Low-temperature medium liquefaction device

A low-temperature medium and liquefaction device technology, applied in the field of liquefaction, can solve the problems of increasing the gas demand of low-temperature medium, easy to form natural convection, unused heat transfer area, etc., and achieve the effect of avoiding convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

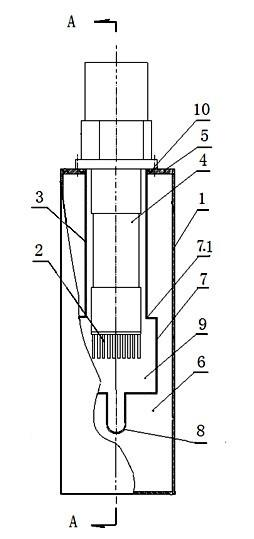

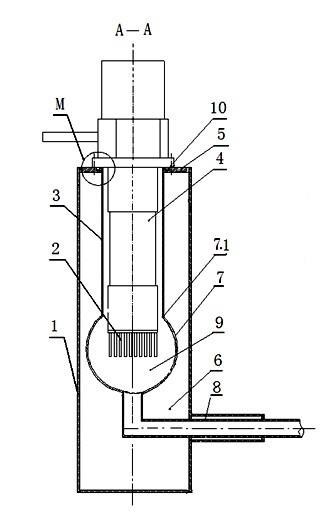

[0025] Example 1: Such as figure 1 , 2 , shown in 3: a low-temperature medium liquefaction device has a Dewar 1 and a heat exchange assembly; 8; wherein the Dewar 1, casing 3, liquid collecting pipe 7 and transmission pipe 8 can be made of stainless steel pipes, and the heat exchanger 2 is made of high thermal conductivity materials, such as red copper. The upper end of the casing 3 is sealed and fixedly connected to the upper part of the inner cavity of the Dewar 1, and the lower end is sealed and fixedly communicated with the liquid collecting pipe 7; one end of the transmission pipe 8 is sealed and fixedly connected with the lower part of the liquid collecting pipe 7, and the middle part is sealed and fixed with the Dewar 1 The other end leads to the outside of Dewar 1; the cold head 4 of the refrigerator is a GM refrigerator cold head, the upper part is sealed and fixedly connected with the Dewar 1, the lower part is in the inner cavity of the casing 3, and the lower en...

Embodiment 2

[0026] Example 2: The difference from Example 1 is that the "O"-shaped sealing ring 10 between the cold head 4 of the refrigerator and the flange 5 is a metal sealing ring; the inner wall of the vacuum area 6 and the outer wall of the Dewar 1 are all sealed. Multi-layer heat insulation layer; the outer wall of casing 3 has a heat insulation layer made of heat insulation material. This embodiment is a heat insulation layer made of ten layers of double-sided aluminized polyester film and glass fiber cloth; For installation, the connecting port 7.1 is on the upper end face; there is a gap of 0.5 mm between the inner wall of the casing 3 and the cold head 4 of the refrigerator.

Embodiment 3

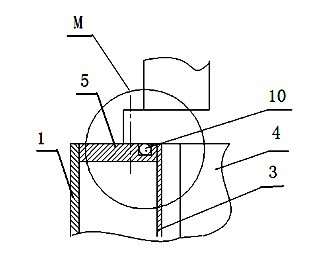

[0027] Embodiment 3: Such as figure 2 , 3 As shown in , 4, the difference from Embodiment 1 is that it is an integrated cryogenic medium liquefaction device with 2 heat exchange components, with 1 Dewar 1 and 2 heat exchange components; each heat exchange component includes 1 A heat exchanger 2, a sleeve pipe 3 and a refrigerator cold head 4; each heat exchange component has a liquid collection pipe 7 and a transmission pipe 8; the upper end of the sleeve pipe 3 is sealed and fixedly connected to the Dewar 1 The upper part of the inner cavity and the lower end are sealed and fixedly communicated with the liquid collecting pipe 7; one end of the transmission pipe 8 is sealed and fixedly connected with the lower part of the liquid collecting pipe 7, the middle part is sealed and fixedly connected with the Dewar 1, and the other end leads to the outside of the Dewar 1; The upper part of the refrigerator cold head 4 is sealed and fixedly connected with the Dewar 1, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com