Multi-phase optical fiber embedded power cable

A power cable and embedded technology, which is applied in the field of multi-phase electric optical fiber embedded power cables, can solve the problems of easy aging and failure of optical fiber cables, and achieve the effect of low cost and improving the degree of informatization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

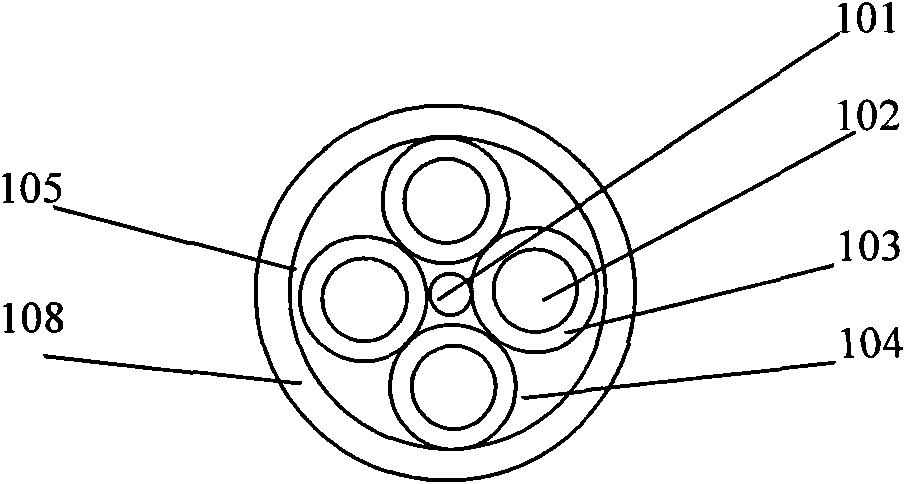

[0023] refer to figure 2 As shown, the present invention includes a multi-phase electric fiber embedded power cable, which includes an optical fiber cable 101, several cable assemblies clamping the optical fiber cable 101, a polymer material filling rope 104 surrounding the optical fiber cable 101 and the cable assembly , the wrapping layer 105 surrounding the optical fiber cable 101 and the cable assembly and the polymer material filling rope 104, the outer sheath 108 surrounding the wrapping layer 105; in the present invention, the copper core cable assembly is preferably 3 groups, which can be The fiber optic cable 101 is clamped. The cable assembly includes a copper core conductor 102 and an XLPE insulating layer 103 wrapping the copper core conductor 102 .

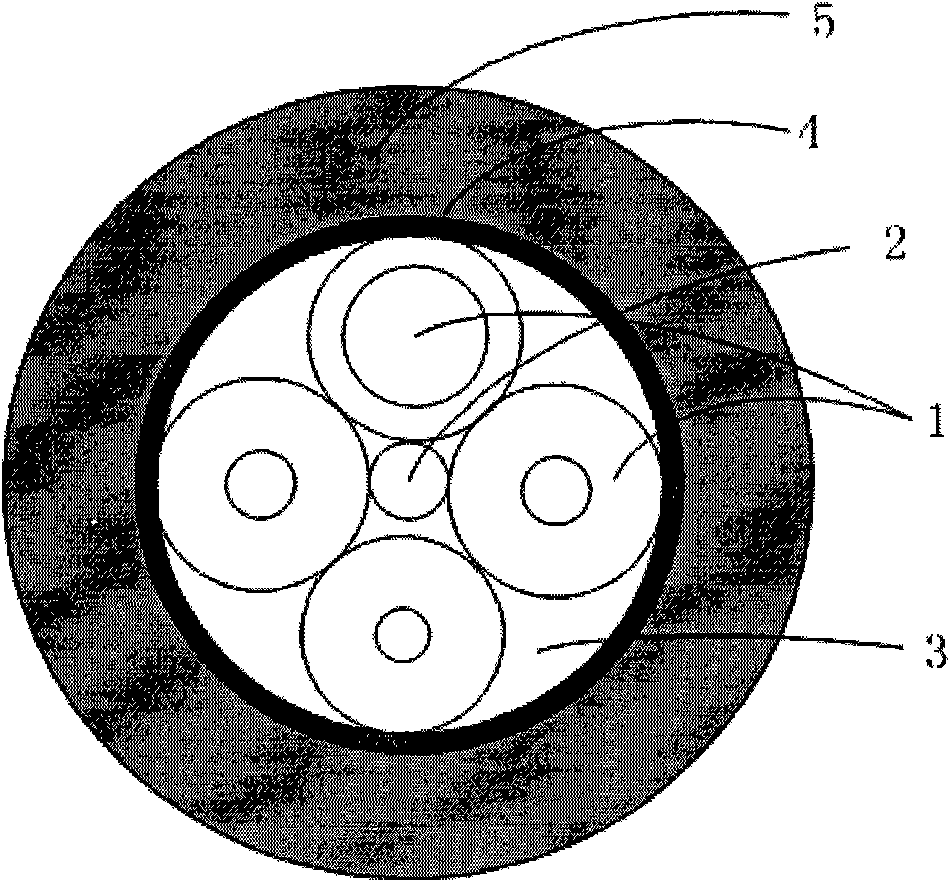

[0024] specific reference figure 1 , the multi-core special structure optical fiber cable used in the patent of the present invention, which includes a glass fiber reinforced resin composite (FRP) strengthening cor...

Embodiment 2

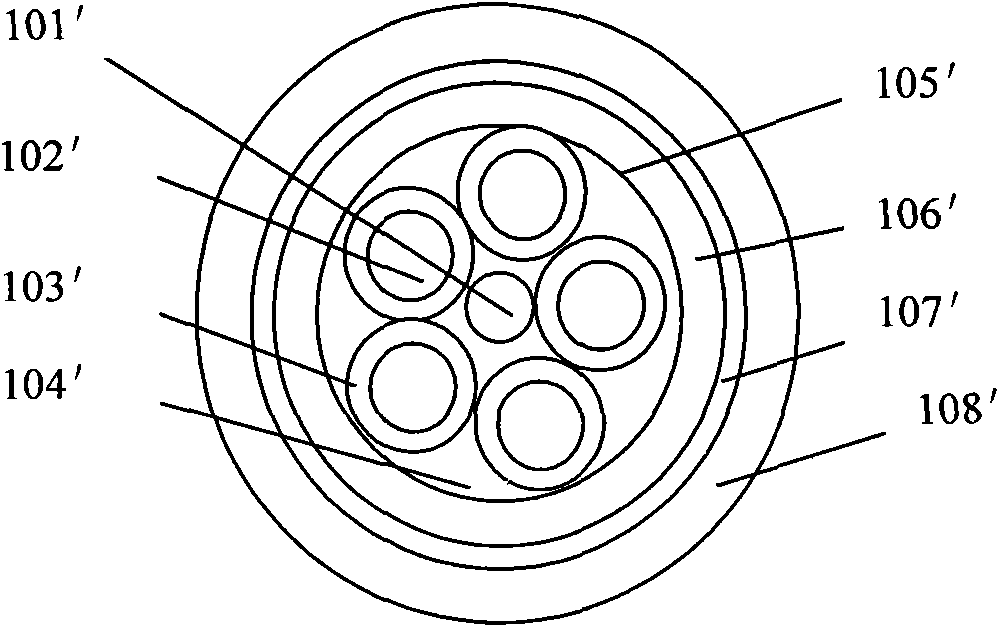

[0034]refer to image 3 As shown, the difference between this embodiment and the first embodiment is that: a polyethylene inner sheath '106 surrounding the wrapping layer 105' and a polyethylene inner sheath '106 surrounding the wrapping layer 105' are provided between the wrapping layer 105' and the outer sheath 108'. Metal armor 107' of sheath 106'.

[0035] Specifically, a multi-phase electrical fiber embedded power cable, which includes an optical fiber cable 101', several cable assemblies clamping the optical fiber cable 101', a filling rope 104' surrounding the optical fiber cable 101' and the cable assembly, wrapping The optical fiber cable 101', the cable assembly and the wrapping layer 105' of the filling rope 104' and the outer sheath 108' surrounding the wrapping layer 105'; the cable assembly includes a copper core conductor 102' and a wrapped copper core conductor XLPE insulating layer 103' of 102'; said optical fiber cable 101' includes a fiber-reinforced compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com