Engine device

A technology for engines and exhaust gas purification devices, which is applied in the direction of power devices, engine components, combustion engines, etc., can solve the problems of exhaust gas temperature drop in exhaust gas purification devices, and achieve the effects of improving versatility and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments embodying the present invention will be described with reference to the drawings. In addition, in the following description, the exhaust gas inflow side is simply referred to as the left side, and similarly, the exhaust gas discharge side is simply referred to as the right side.

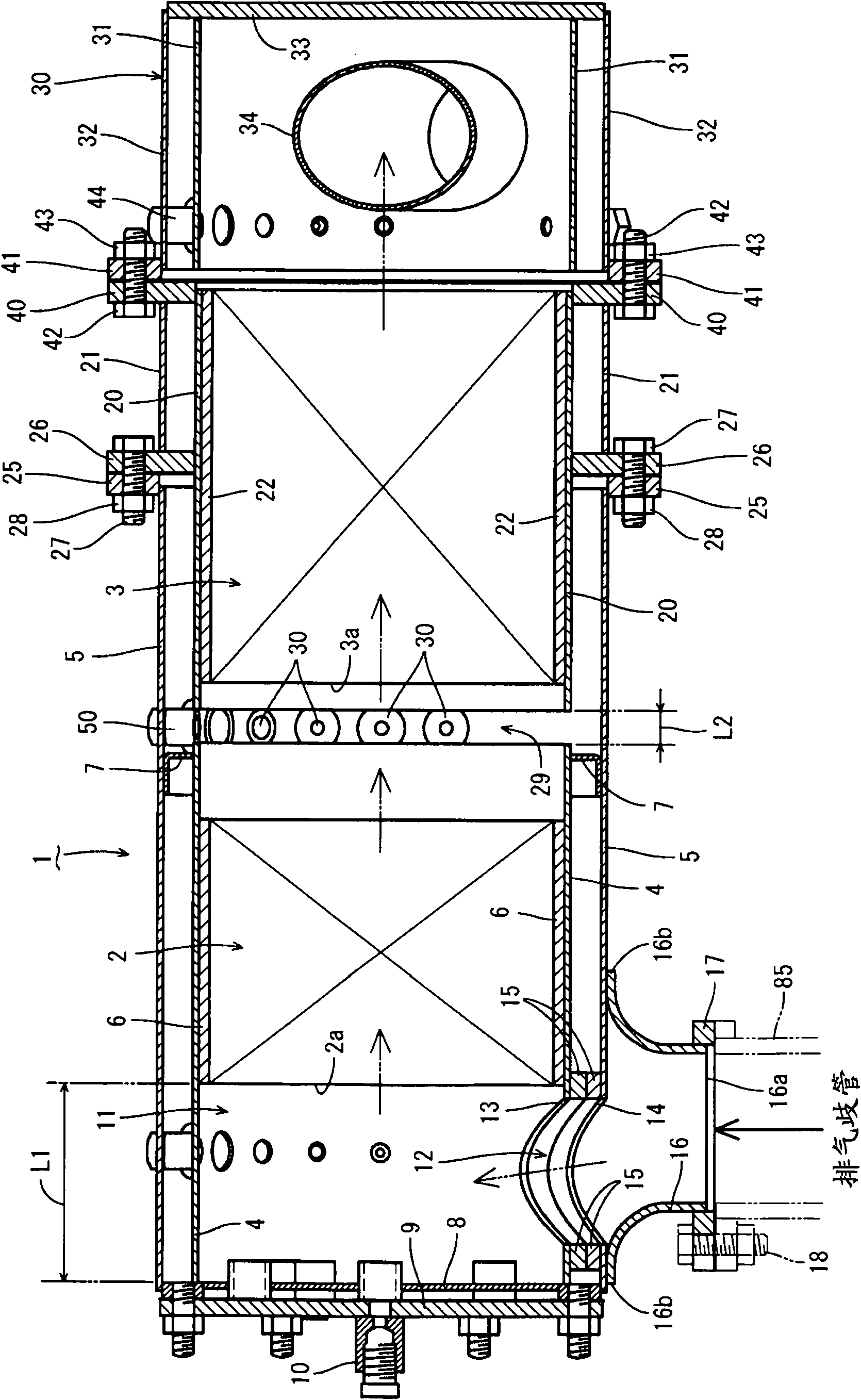

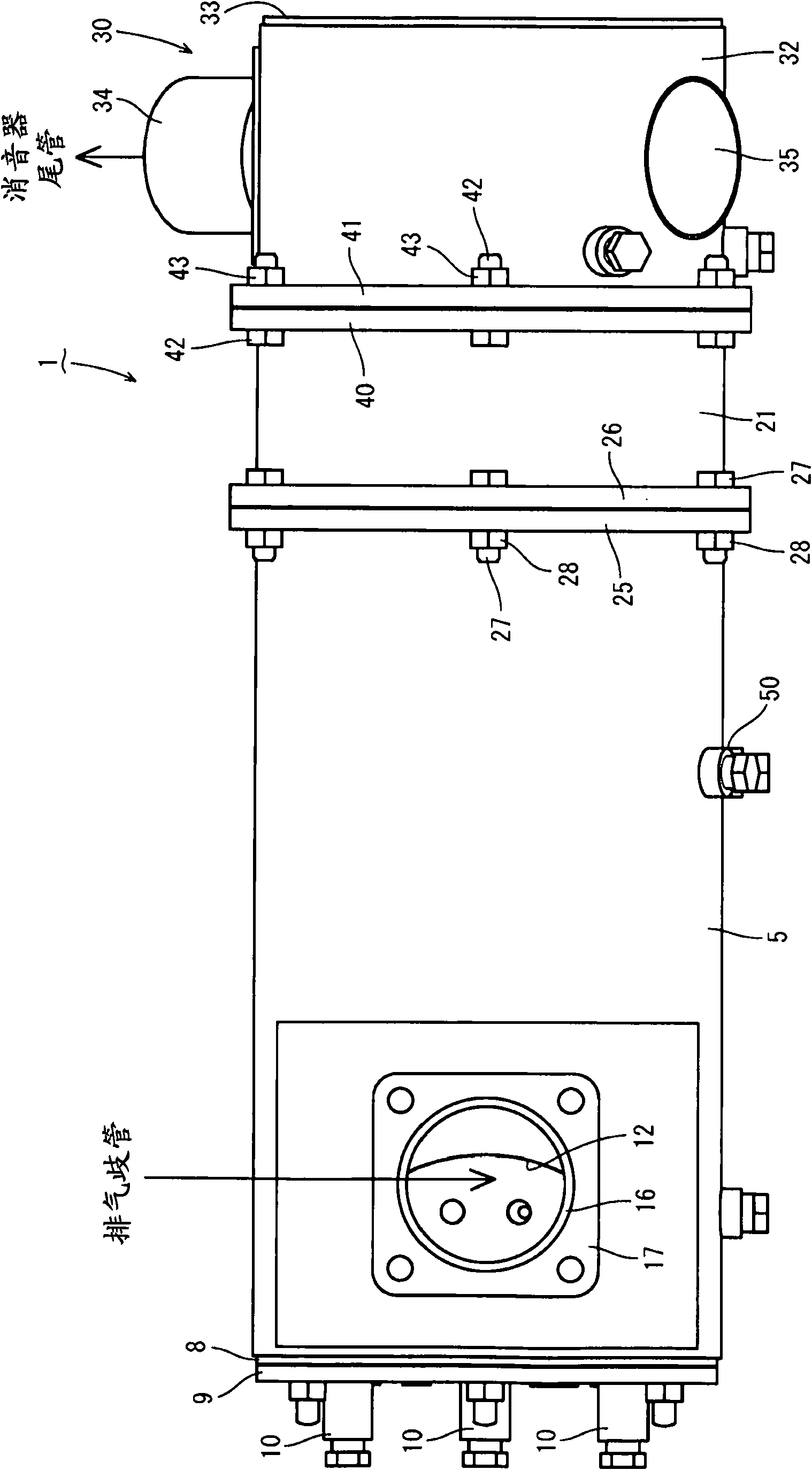

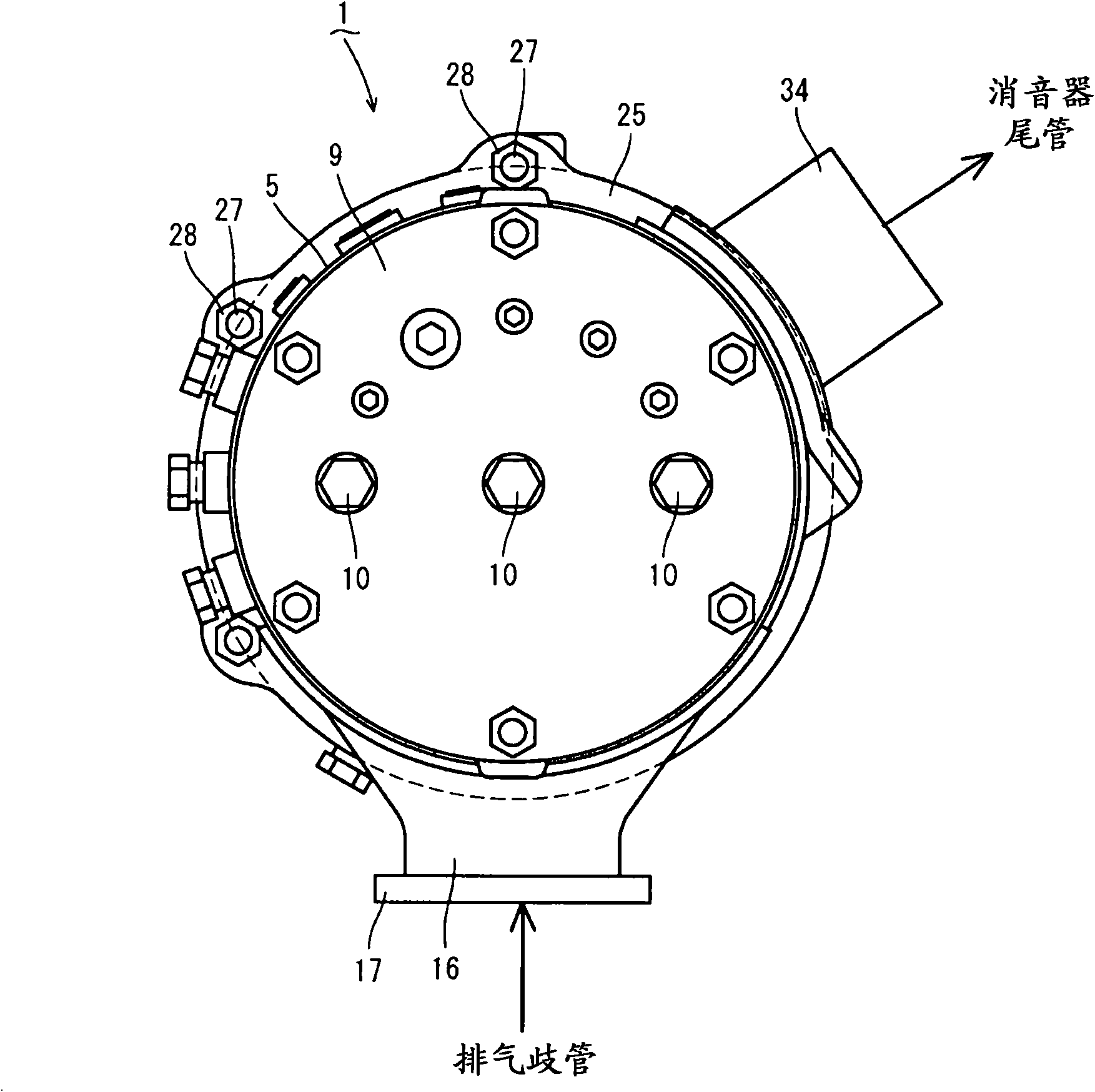

[0047] First, refer to Figure 1 to Figure 9 The overall structure of the exhaust gas purification device will be described. like Figure 1 to Figure 5 As shown in FIG. 1 , a continuously regenerative diesel particulate filter 1 (hereinafter, referred to as DPF) is provided as the exhaust gas purification device of the present embodiment. The DPF1 is used to physically trap particulate matter (PM) and the like in exhaust gas. DPF1 is in the direction of exhaust gas movement (from figure 1 Diesel oxidation catalyst 2 such as platinum that generates nitrogen dioxide (NO2) and a honeycomb structure soot filter that continuously oxidizes and removes captured particulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com