Process and equipment for preserving and refining plant oil

A kind of refining equipment and vegetable oil technology, which is applied in the fields of fat oil/fat refining, food science, edible oil/fat, etc., can solve the problems of shortened product shelf life and peculiar smell, and achieve the effects of easy implementation, extended shelf life and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

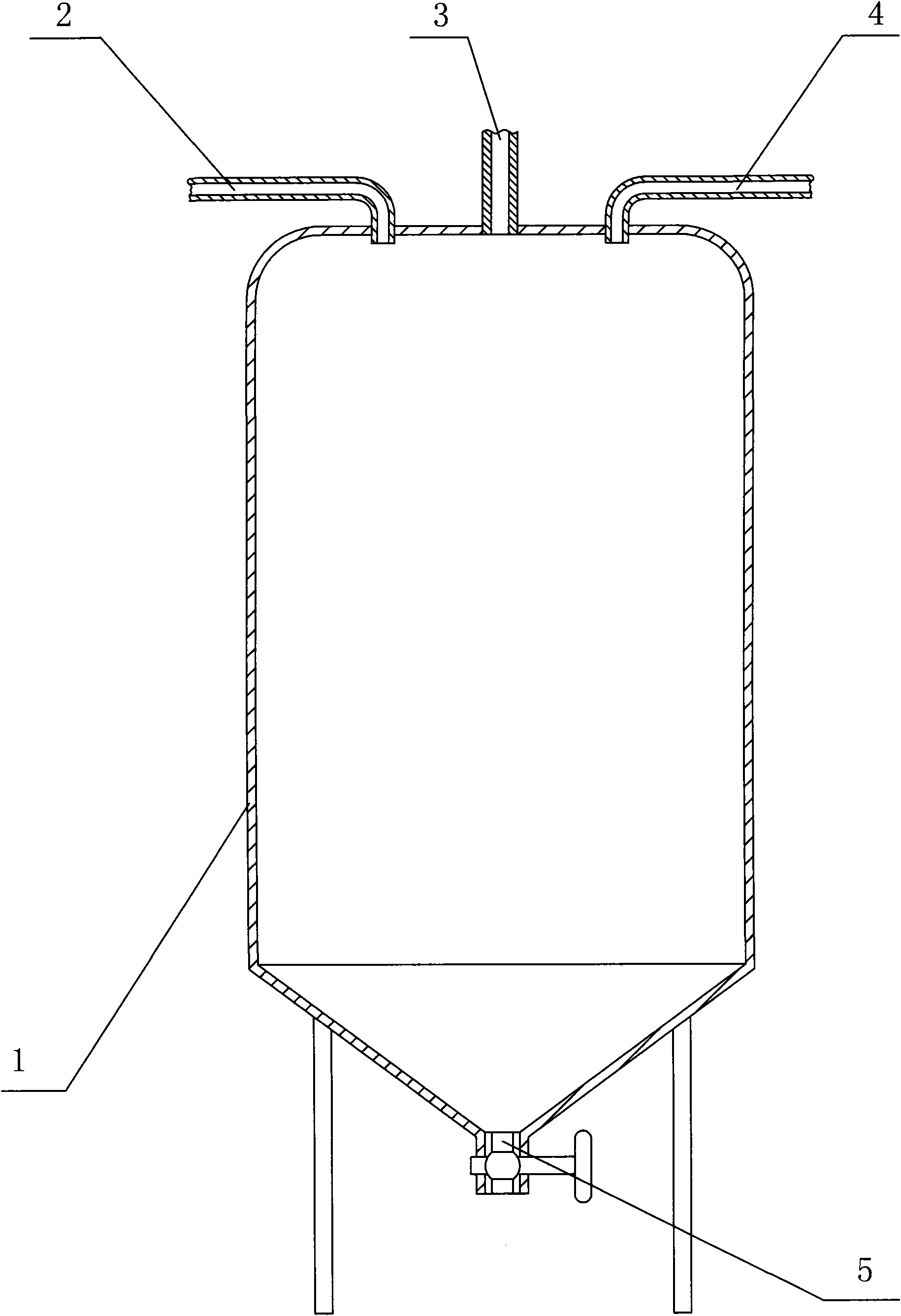

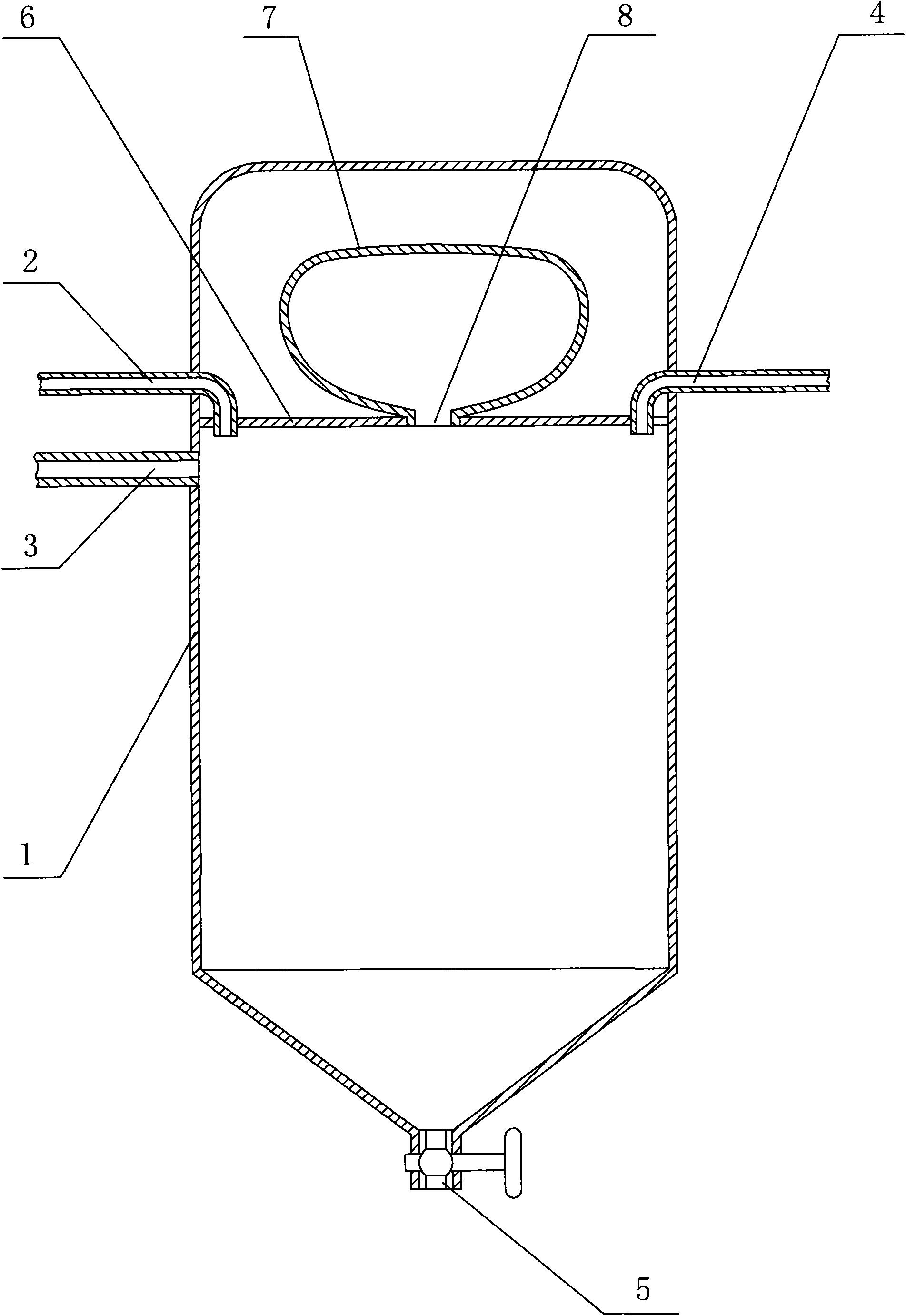

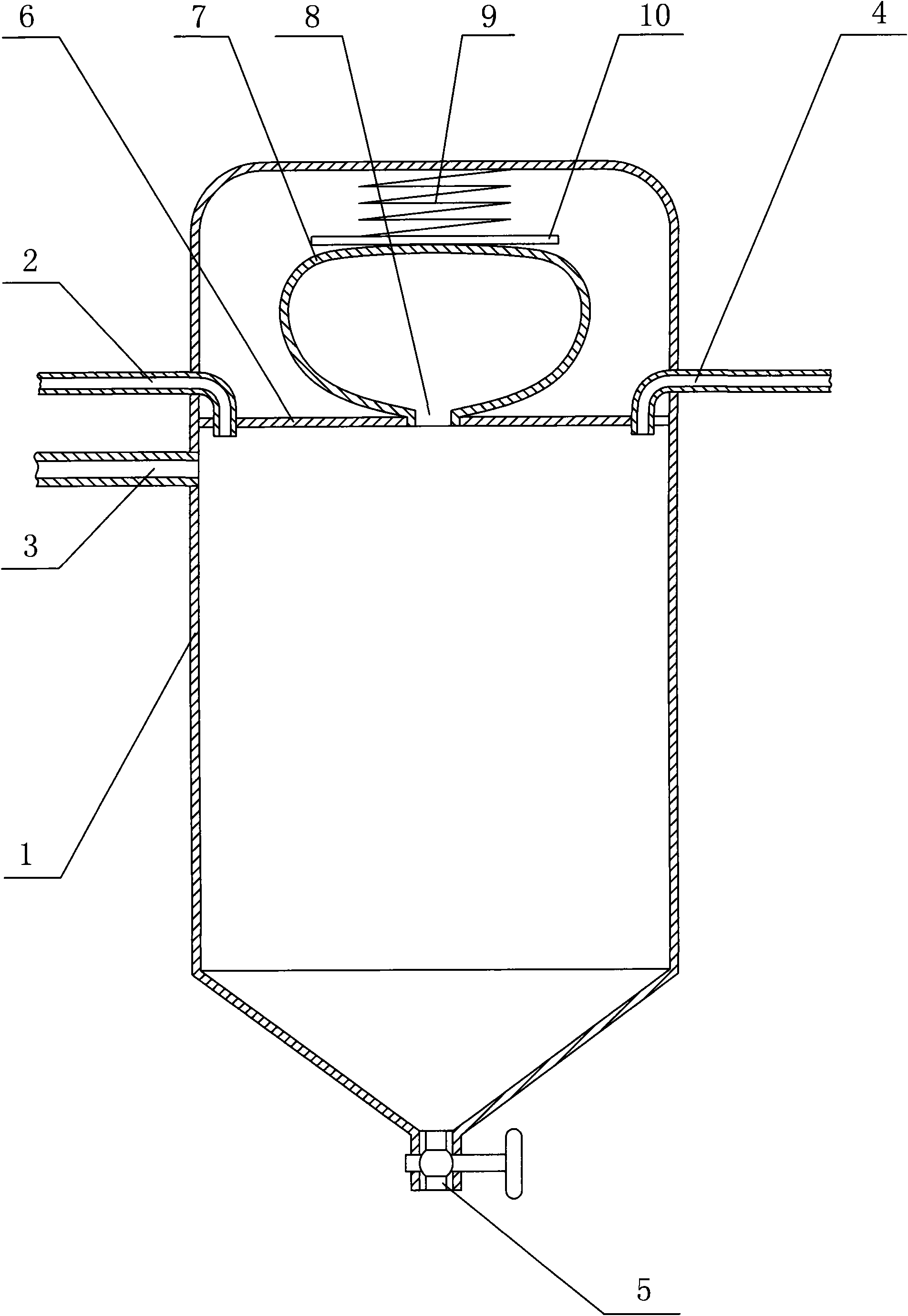

[0021] The first embodiment: as figure 1 The shown tank body 1 represents the container used for oil refining, which can be deacidification tank, degumming tank, decolorization tank, deodorization pot, finished oil tank and filling equipment used for vegetable oil refining, and can be used crude oil tank for edible vegetable oil processing, Hydration tank, alkali refining tank, dewaxing tank, finished oil tank and filling equipment, the tank body 1 is provided with an oil inlet 3 and an oil outlet 5. Of course, the tank body 1 is also provided with other devices such as brackets, which are omitted because they are irrelevant to the description. It is characterized in that two pipes are arranged above the tank body 1, one is an exhaust pipe 2, and the other is a nitrogen filling pipe 4. Exhaust pipe 2 can be a natural exhaust pipe or a one-way pipe that does not advance, and its effect is to get rid of the oxygen in the container. There are many ways to discharge oxygen, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com