Method for reducing center martensitic structure of high-carbon steel coil rod

A wire rod core and martensite technology, which is applied in the field of martensite structure in the core of hot-rolled wire rods, can solve the problems of extensive control process, reducing the content of martensite structure in the core, and short length of the air-cooling line, etc. The effect of reducing cup-cone fracture and plied wire breakage, reducing martensitic structure and improving plasticity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

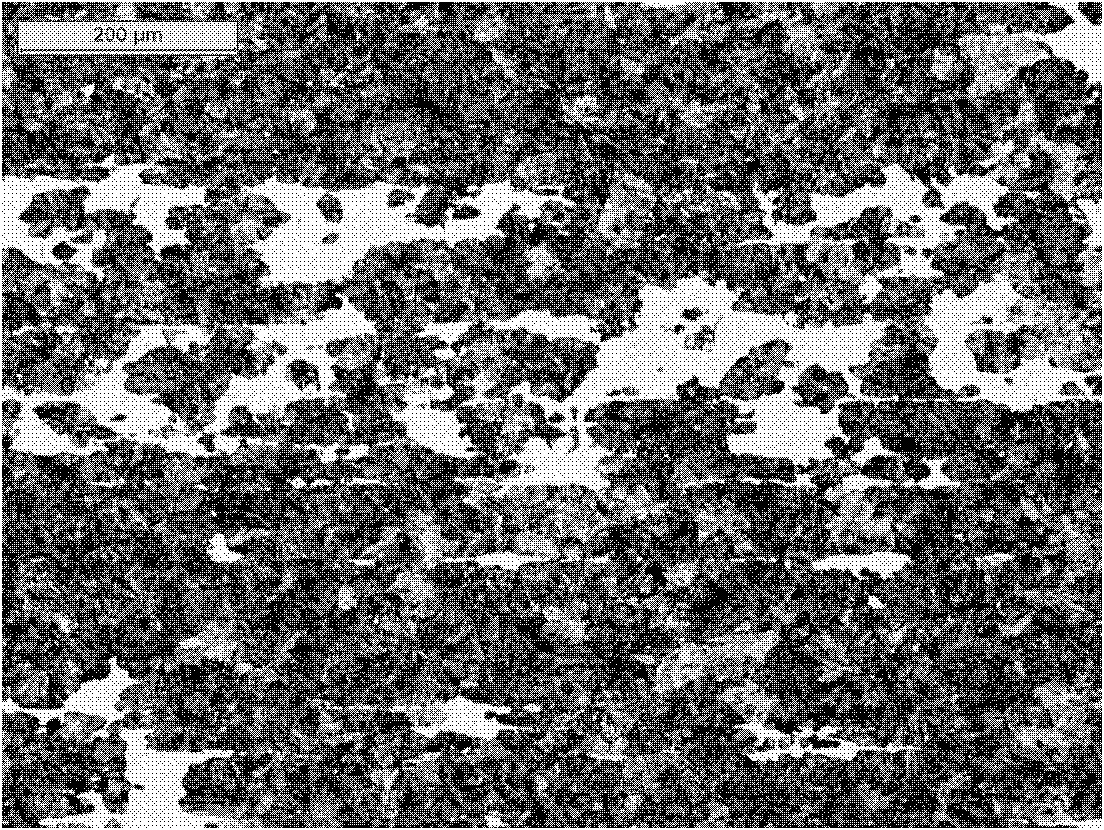

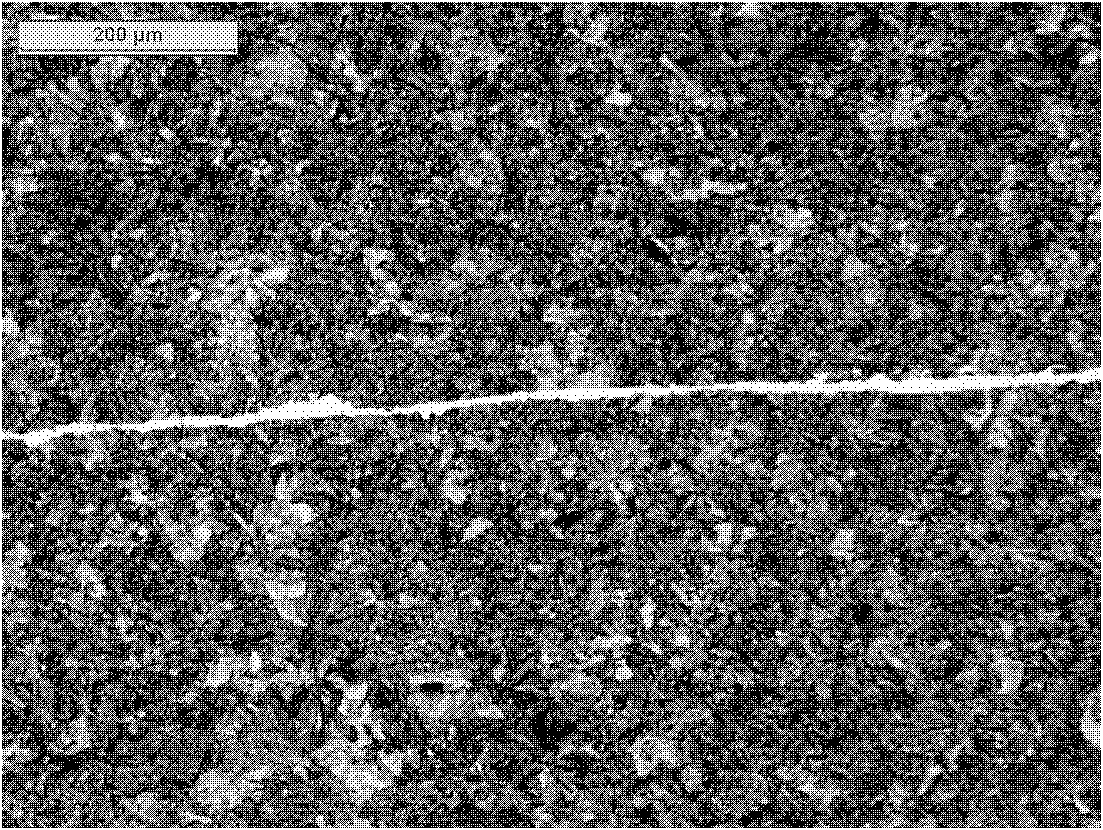

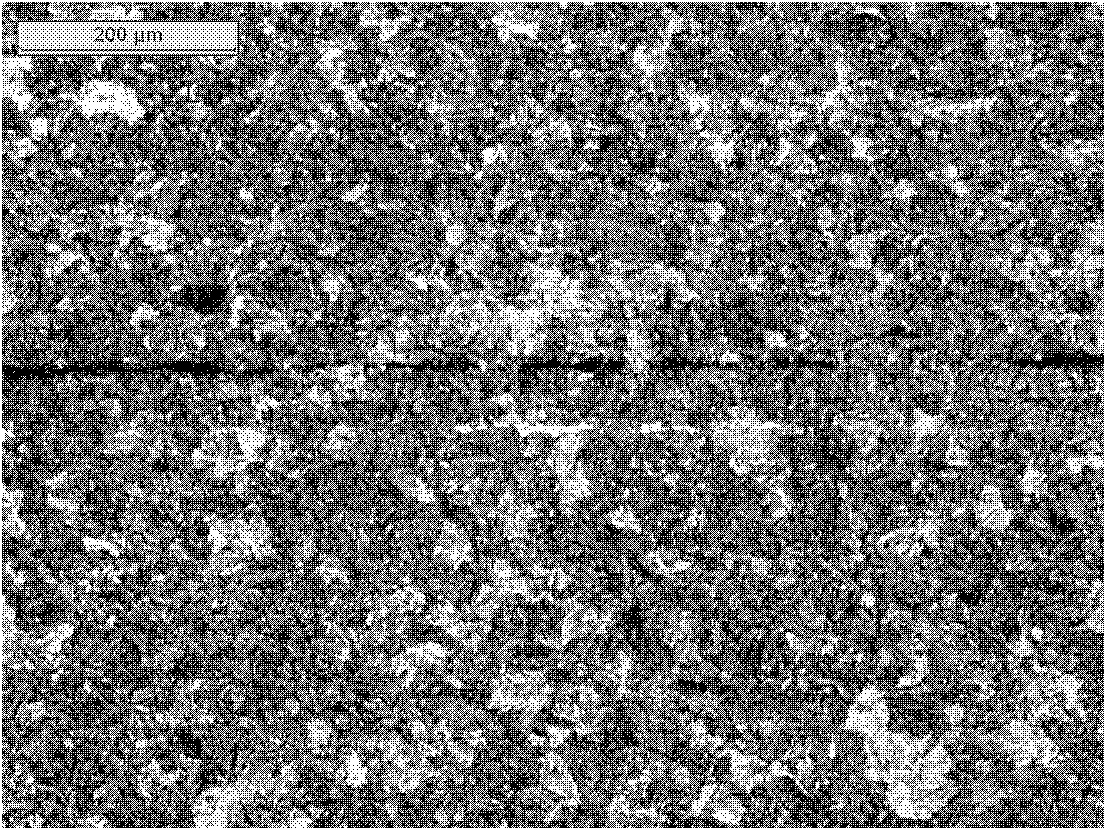

[0024] The present invention is used in the 160mm wire rod of Shougang 2 It has been applied in the production of ¢12.5mm 82B-1 wire rod, and the martensitic structure in the core of the wire rod has been significantly reduced. The specific process is as follows:

[0025] 1. The temperature in the heating section of the heating furnace is controlled at 1080-1110°C, the soaking temperature is controlled at 1060-1070°C, and the soaking section takes 30 minutes.

[0026] 2. Rough rolling adopts 6-pass deformation, and the elongation coefficients of each pass are 1.29, 1.26, 1.50, 1.22, 1.35, 1.33. Intermediate rolling adopts 6-pass deformation, and the pass elongation coefficients are 1.38, 1.28, 1.40, 1.30, respectively. 1.38, 1.26, the finishing rolling process adopts the 4-stand continuous rolling method, and the finishing rolling inlet temperature is controlled at 900-940°C.

[0027] 3. Adjust the fan opening of the air-cooling line. After spinning, the cooling rate of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com