Non-homogenous multi-layer core holder for CT (computed tomography) scanning

A core holder, CT scanning technology, applied in instruments, scientific instruments, suspension and porous material analysis, etc., can solve problems such as impermeability, achieve excellent dielectric properties, good self-lubrication, and reduce experimental effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

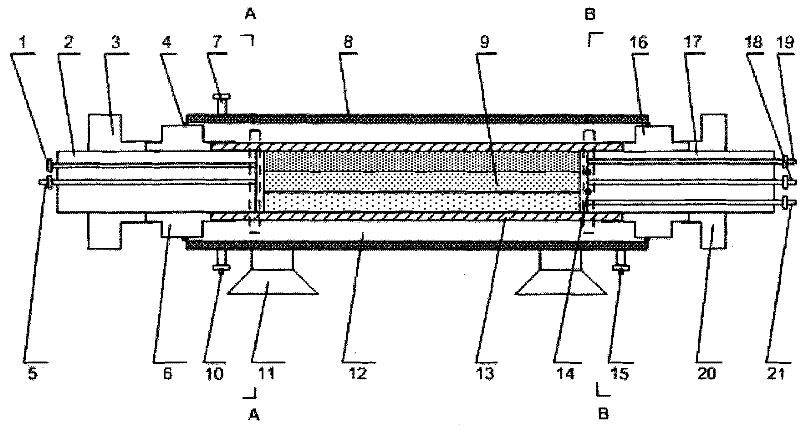

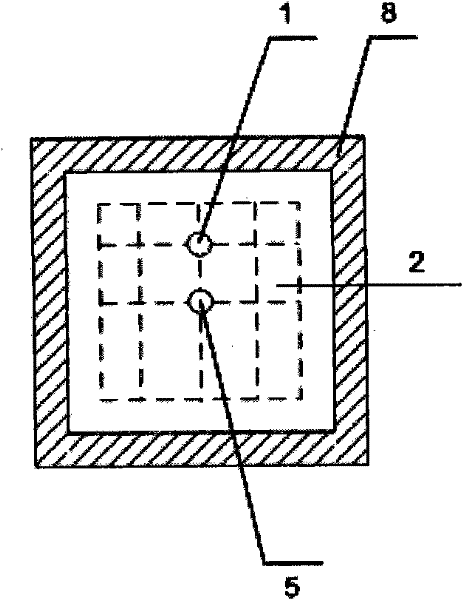

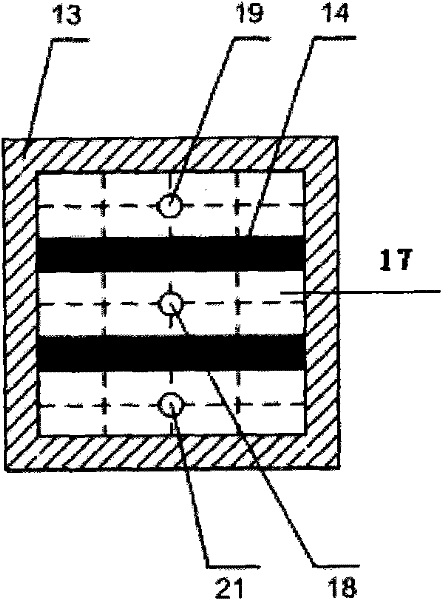

[0019] Example 1 Heterogeneous Multilayer Core Holder for CT Scanning

[0020] Figure 1-3 Shown is a schematic structural diagram of a heterogeneous multilayer core holder for CT scanning in a preferred embodiment of the present invention, a heterogeneous multilayer core holder for CT scanning consists of a housing 8, rubber Tube 13, rock core left plug 2, rock core right plug 17, left fixed sleeve 6, right fixed sleeve 16, left fastening sleeve 3, right fastening sleeve 20 and fixed bracket 11 constitute;

[0021] The polyether ether ketone resin casing 8 is cylindrical, and the rubber casing 13 is placed inside the casing 8, coaxial with the casing 8; the multi-layer core model 9 is located in the inner cavity of the rubber casing 13; the left plug of the rock core 2, the right plug of the rock core 17 is detachably abutted against the two ends of the multi-layer core model 9 in the rubber tube 13, and its shape and size are consistent with the inner wall of the rubber tub...

Embodiment 2

[0022] Example 2 CT scan evaluation experiment of water flooding efficiency of heterogeneous model in layer

[0023] Firstly, three natural oil reservoir cores collected from different depths were taken to make cuboid single-layer core models with the same specifications. Measure the porosity and air permeability of each single-layer core model respectively; saturate each single-layer core with formation water, and measure the water-phase permeability respectively; then carry out oil flooding on each single-layer core respectively, and measure the oil permeability after reaching the state of bound water; The effective permeability of the facies and calculate the irreducible water saturation of each monolayer core.

[0024] The rock cores of each layer containing irreducible water are placed in the rock core chamber of the rock core holder described in embodiment 1 according to the anti-rhythm arrangement; the rock core upper and lower plugs and upper and lower fixing sleeves o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com