Humidifying and purifying module

A purification module and cement technology, which is applied in the field of air purification, humidification, and cooling devices, and can solve the problems of complicated production, difficult cleaning of air purification membranes, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for manufacturing a humidifying and purifying module, the method comprising the following steps:

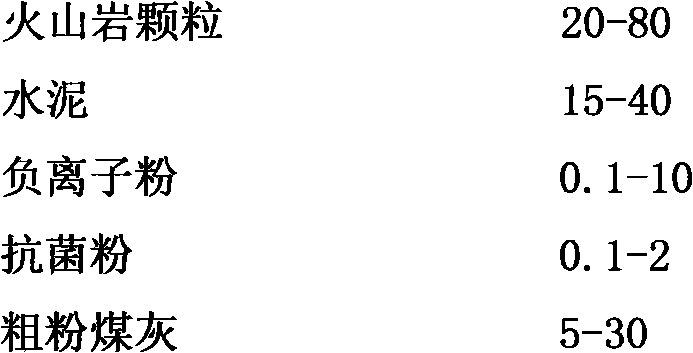

[0013] (1) Prepared according to the following weight percentages:

[0014]

[0015] (2) Put the prepared materials into the blender and stir for 2 minutes, add 9 kg of water, and stir thoroughly for 3-5 minutes.

[0016] (3) Send the stirred material into the mold for compact vibration to form, and the formed product is packaged and put into storage after curing.

Embodiment 2

[0018] A method for manufacturing a humidifying and purifying module, the method comprising the following steps:

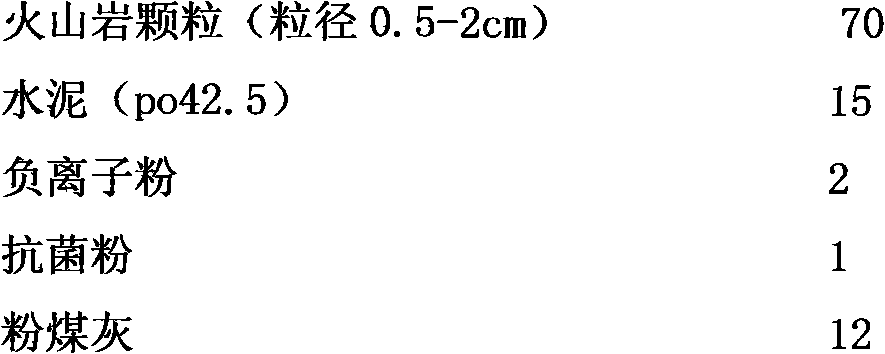

[0019] (1) Configured according to the following weight percentages:

[0020]

[0021] (2) Put the prepared materials into the blender and stir for 2 minutes, add 11 kg of water, and stir thoroughly for 3-5 minutes.

[0022] (3) Put the stirred material into the mold and vibrate compactly to form it. After standing for 8 hours, the formed product is washed with water. The processed product is packaged and put into storage after curing.

Embodiment 3

[0024] A method for manufacturing a humidifying and purifying module, the method comprising the following steps:

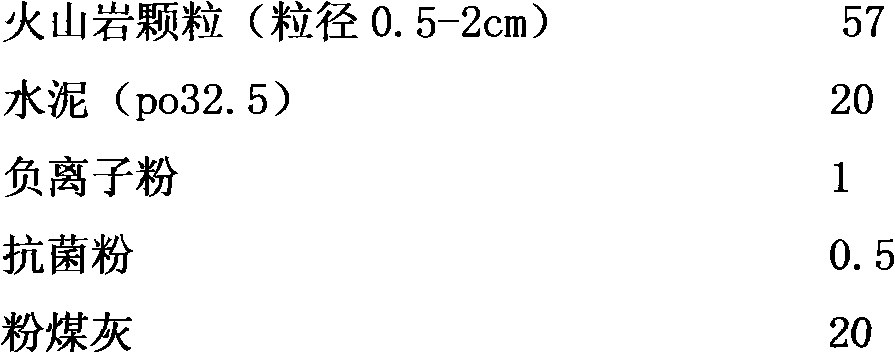

[0025] (2) Prepared according to the following weight percentages:

[0026]

[0027] (2) Put the prepared materials into the blender and stir for 2 minutes, add 9 kg of water, and stir thoroughly for 3-5 minutes.

[0028] (3) Put the stirred material into the mold and vibrate to form it. After curing, the formed product will be sandblasted, and the processed product will be packed into the warehouse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com