Five-axis NC (numerical control) milling method for internal surfaces of bent pipes

A processing method and CNC milling technology, which are applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of difficulty in machining the inner surface of elbow parts, and achieve easy guarantee of machining accuracy, transmission accuracy, and reduction of Effects of cutting shock loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

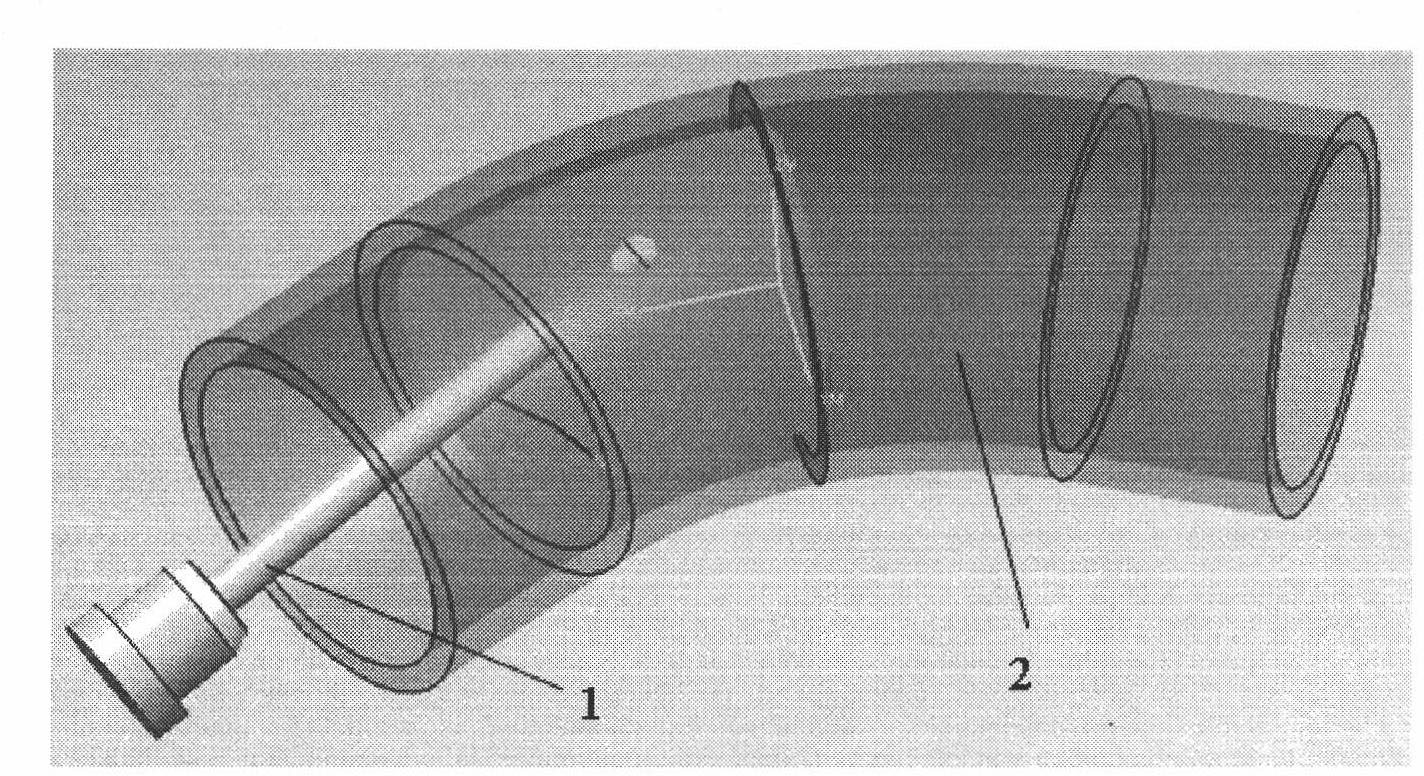

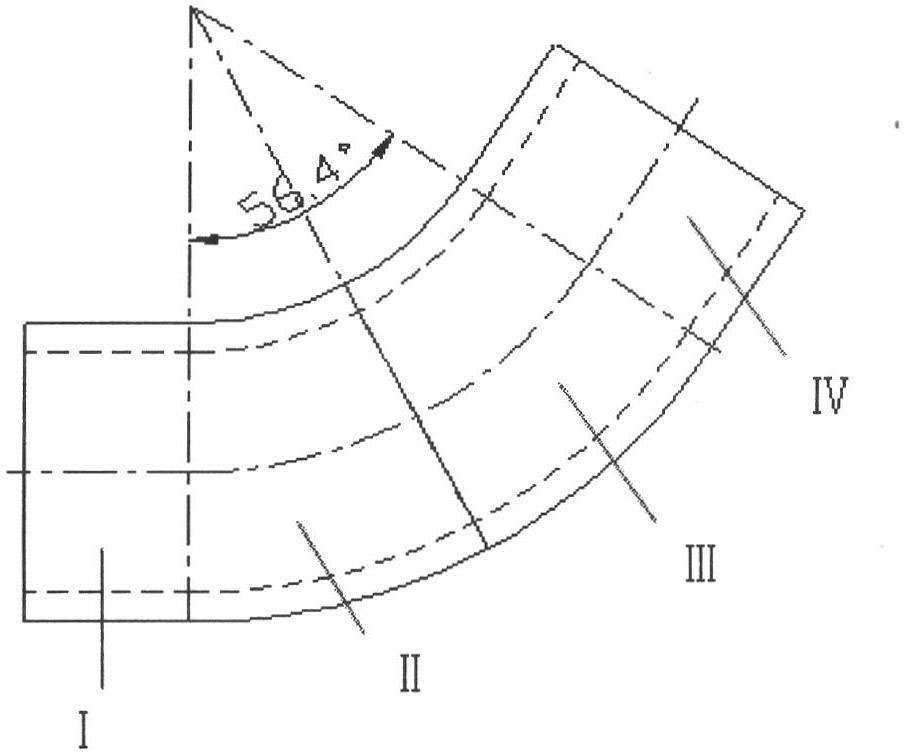

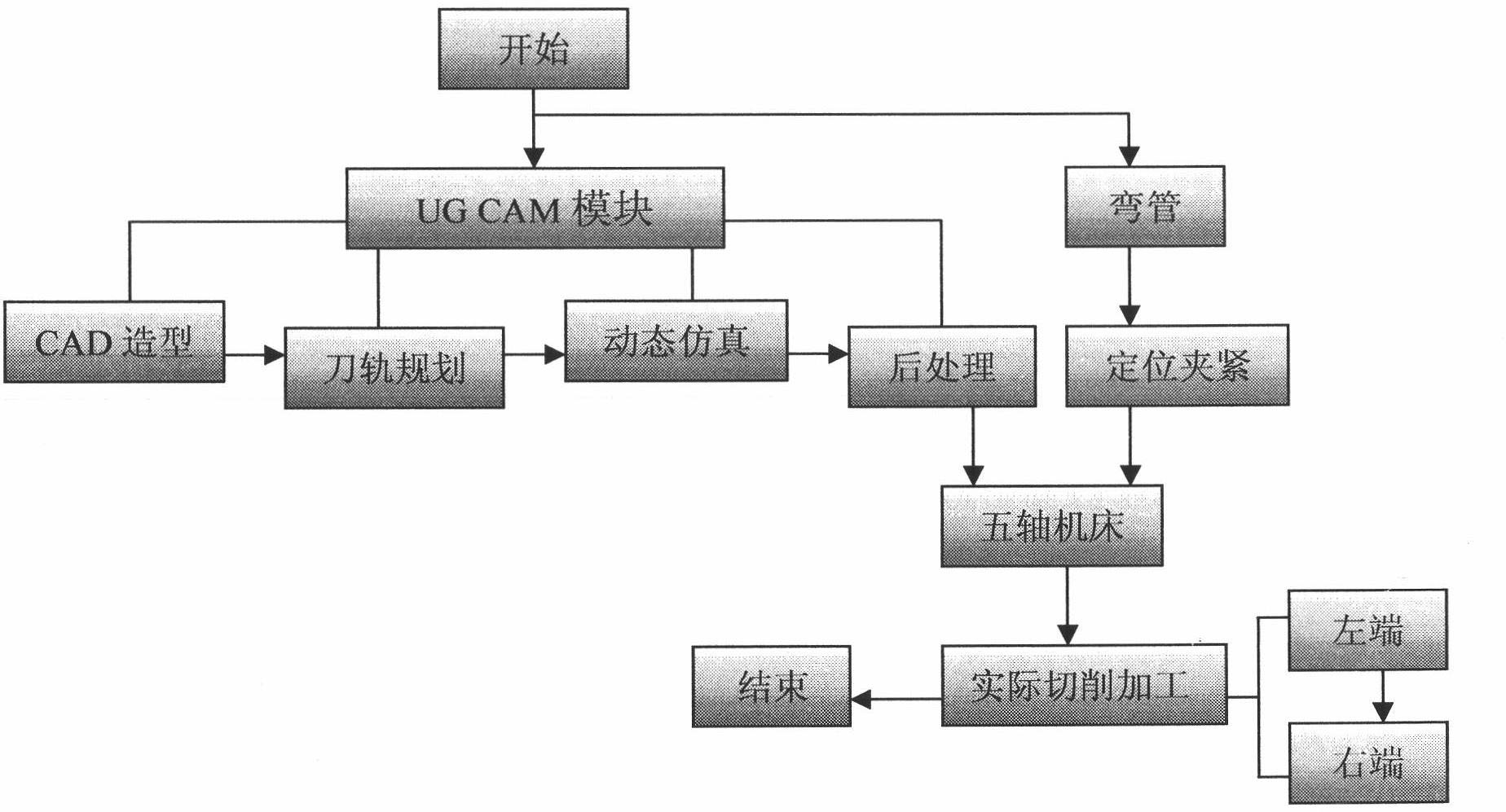

[0019] The specific embodiments of the present invention will be described in detail with reference to the accompanying drawings and technical solutions. figure 1 It is a schematic diagram of the inner surface processing of the elbow. As shown in the figure, the machine tool spindle directly drives the extended ball nose tool 1 to perform cutting motion. During processing, the cutting movement of the tool is along the circumference of the inner surface of the elbow part 2 to ensure that the centerline of the tool axis always bends. The fixed point of the circle center of the pipe end; after processing the first and second areas I, II of the left end of the elbow, the tool withdraws from the elbow and moves to the right end of the elbow to process the third and fourth areas III, IV , see attached figure 2 ;Specific steps are as follows,

[0020] The specific implementation of the processing object is a typical elbow type part, the structure is symmetrical, the outer surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com