Mechanical brake system for urban rail vehicles and motor train units

A technology for mechanical braking and urban rail vehicles, which is applied to railway braking systems, braking parts, mechanical equipment, etc., can solve the problems of limited installation space of brake discs, difficult installation and disassembly, and high manufacturing costs, and achieves simple structure, The effect of low manufacturing cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

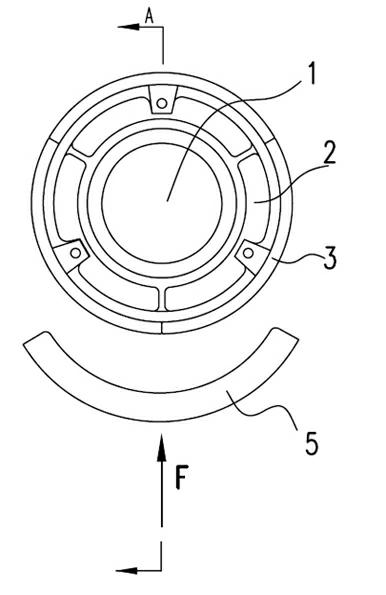

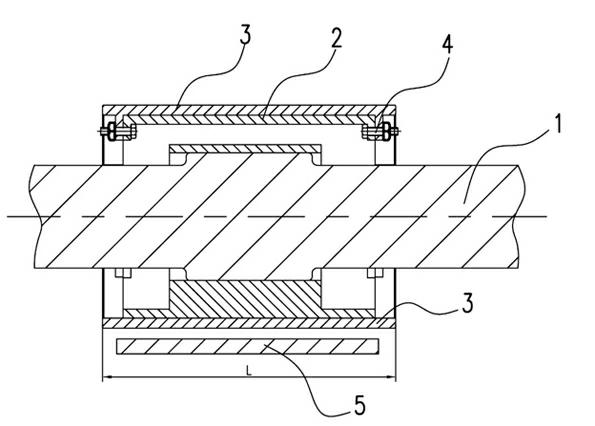

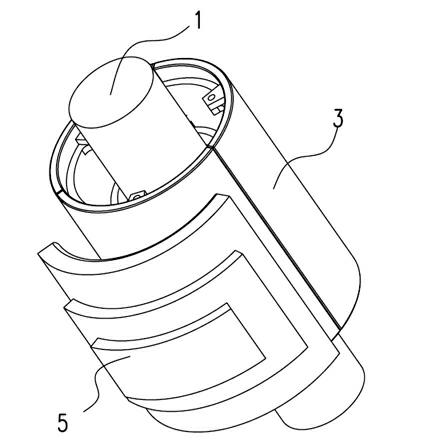

[0025] A mechanical brake system for urban rail vehicles and EMUs, such as figure 1 and 2 As shown, it includes a brake disc mounting seat 2 sleeved on the axle 1, and the axle 1 and the brake disc mounting seat 2 are interference-connected. At least two brake discs 3 are installed in the circumferential direction of the brake disc mounting seat 2, and the outer side of the brake disc 3 is provided with a plurality of brake discs 3 that brake the brake disc 3 under the action of the braking force F. The brake pad 5 is installed on the bogie frame of the rolling stock. Under the action of the braking force F, the brake pads 5 installed on the bogie frame of the locomotive and the brake discs 3 are bonded to convert the kinetic energy of the locomotive into heat energy to realize the braking of the train.

[0026] Such as Figure 5 As shown, the brake disc 3 is arc-shaped, such as image 3 As shown, the brake pads 5 are arc-shaped, and there may be multiple brake pads. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com