Multielement-doped bismuth titanate group lead-free piezoceramic material and preparation method thereof

A technology of lead-free piezoelectric and ceramic materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of limited development and achieve The effect of less piezoelectric performance and dielectric performance, less drop, and improved piezoelectric performance and dielectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

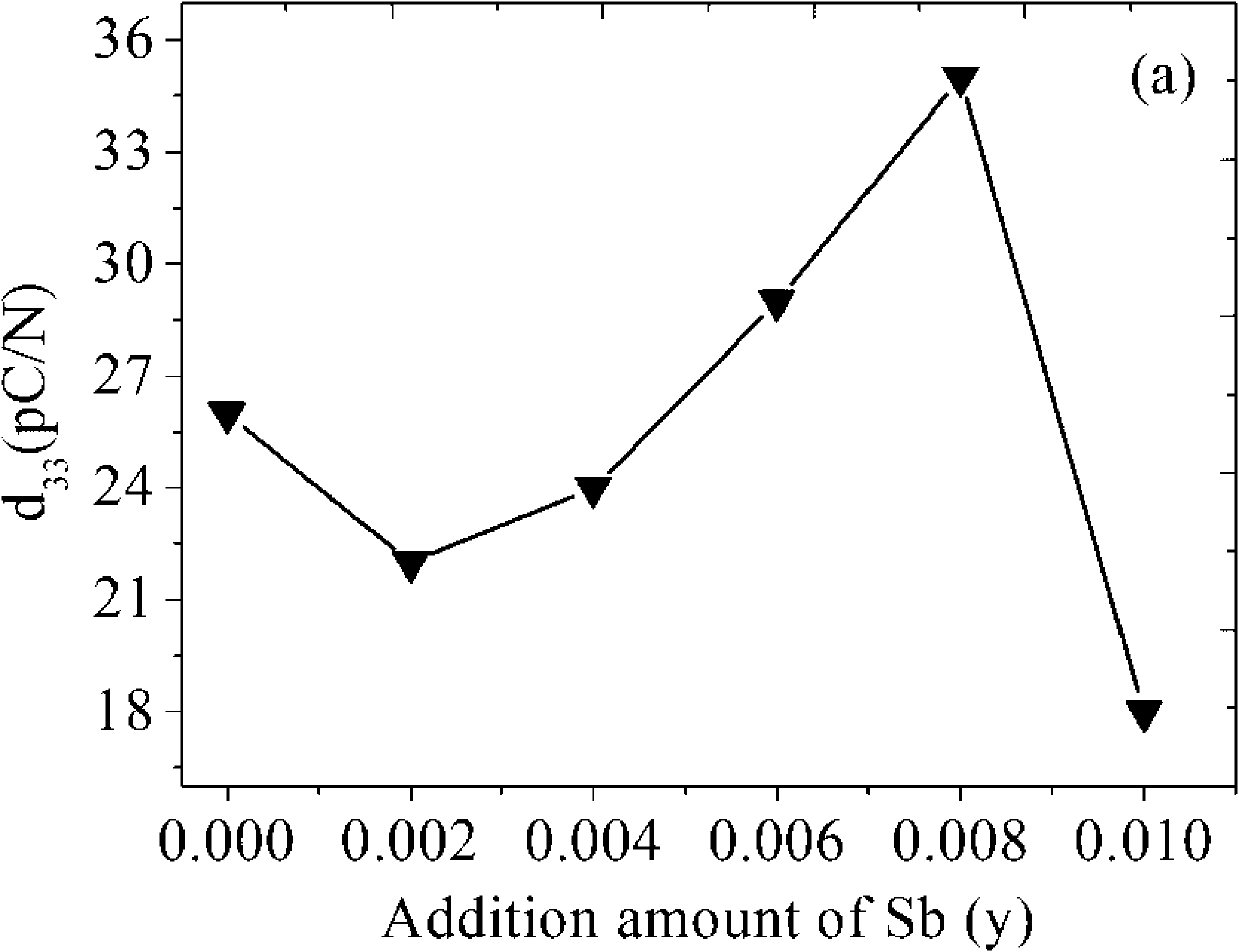

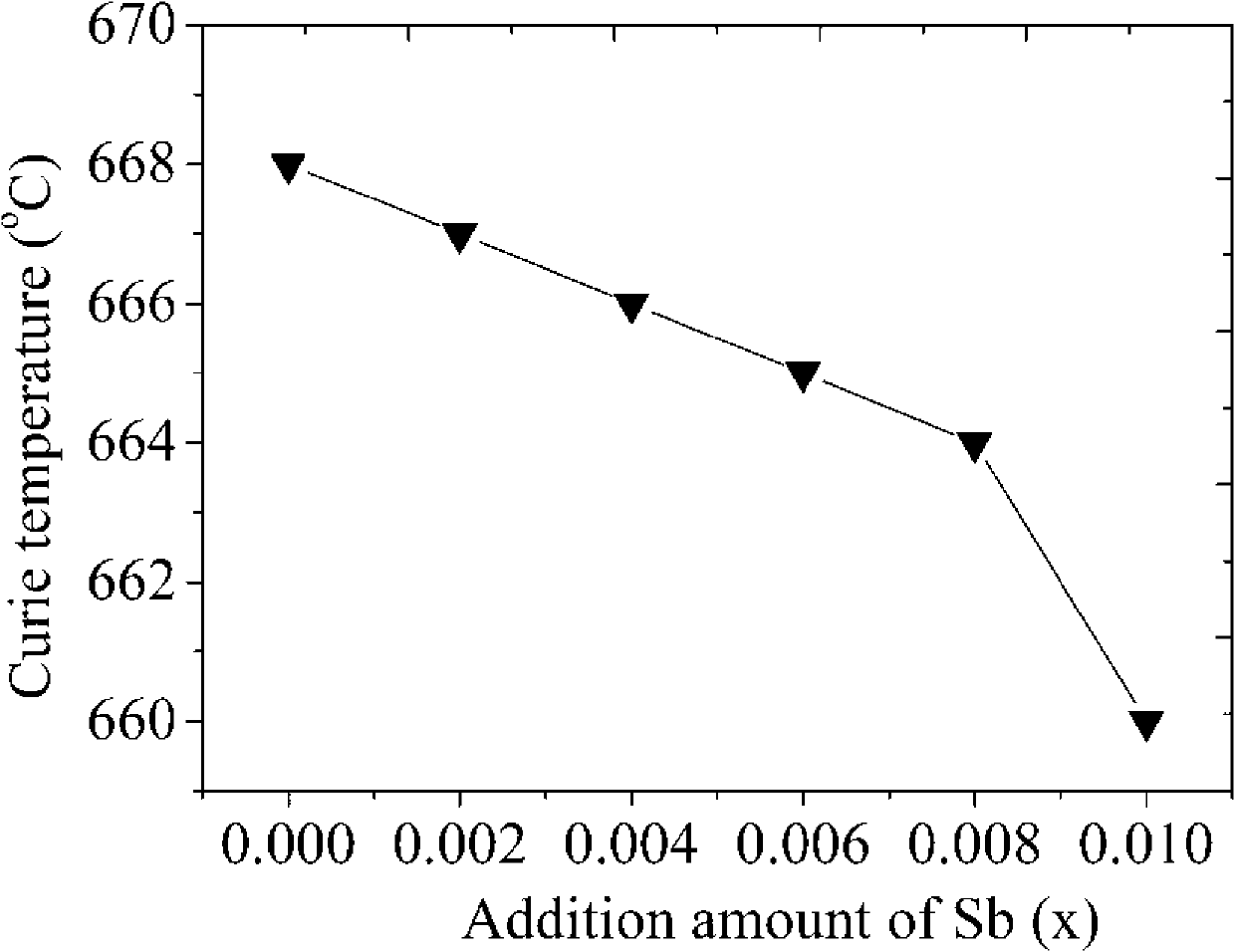

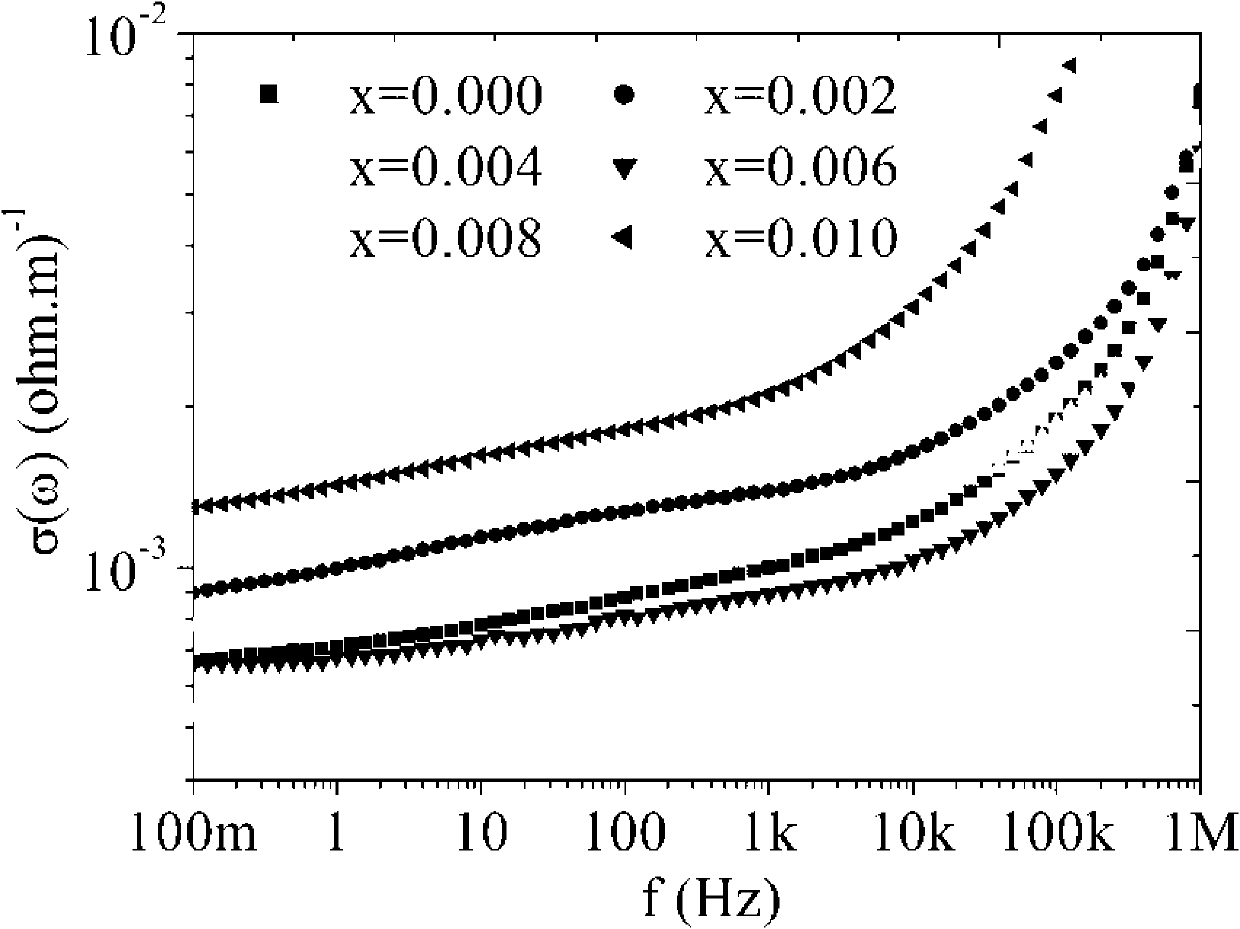

[0024] The test results are as follows: d 33 =35pC / N, Curie temperature Tc=660℃. Conductivity, dielectricity and lossy see image 3 and Figure 4 . exhibited good electrical conductivity and dielectric properties.

[0025] Example 2

Embodiment 2

[0027] The test results are as follows: d 33 =29pC / N, Curie temperature T c =665°C. Conductivity, dielectricity and lossy see image 3 .

[0028] Example 3

Embodiment 3

[0030] The test results are as follows: d 33 =24pC / N, Curie temperature T c =666°C. Conductivity, dielectricity and lossy see image 3 .

[0031] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com