Non-yellowing anti-graffiti resin for synthetic leather as well as preparation method of the resin

An anti-graffiti resin and synthetic leather technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of low yellowing resistance, low hydrolysis resistance and high temperature resistance, insufficient wear resistance and bending resistance, complex processing technology, etc. Achieve the effects of firm bonding, excellent wear resistance and bending resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

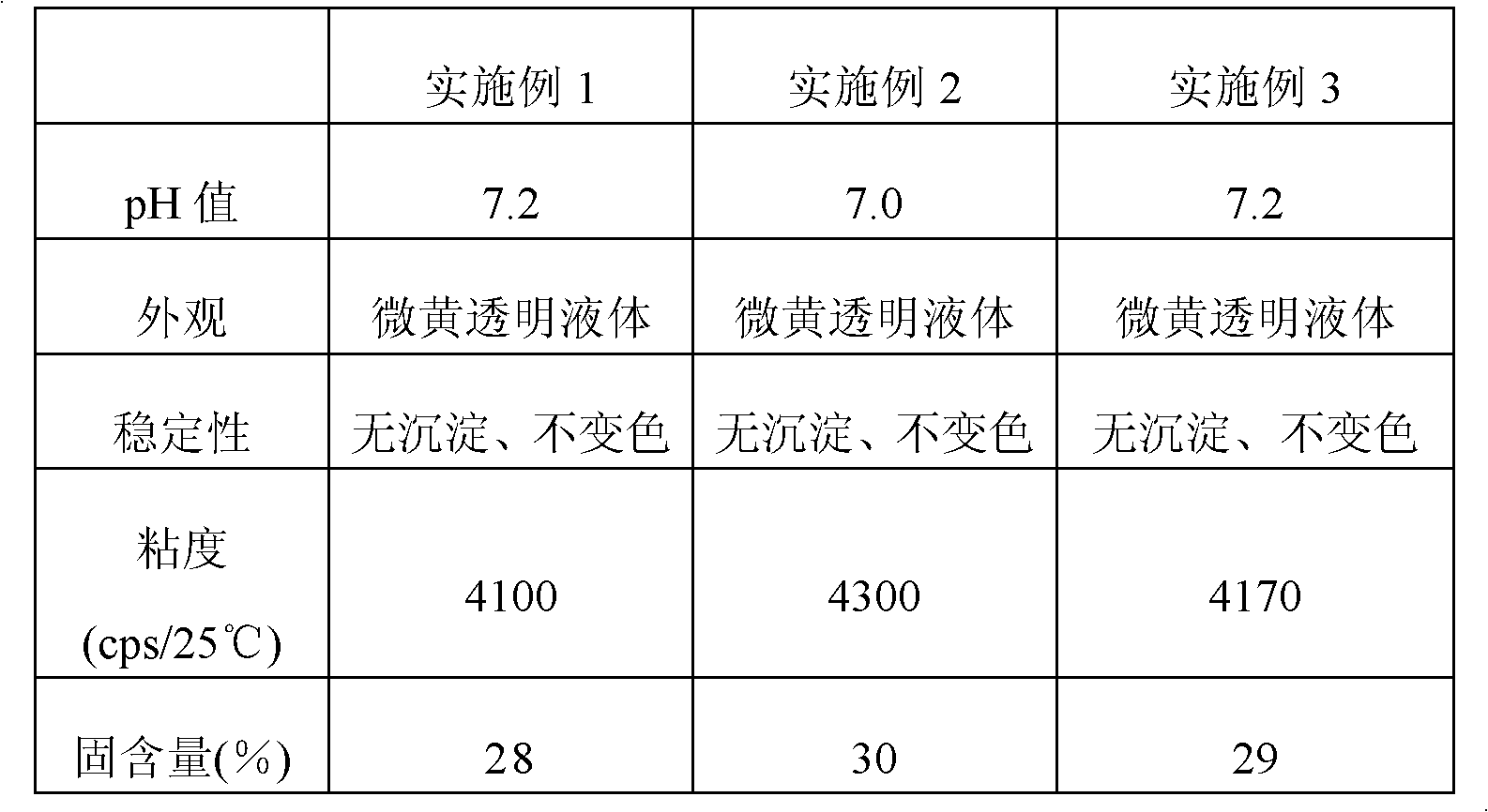

Examples

Embodiment 1

[0021] The non-yellowing anti-graffiti resin for synthetic leather consists of 35 parts by weight of polyether polyurethane resin, 45 parts by weight of DMF, 10 parts by weight of acetone, 3 parts by weight of dimethyl siloxane, 2 parts by weight of organic silicone oil, and 1.5 parts by weight of anti-graffiti additive. It is composed of 0.5 parts by weight of anti-ultraviolet absorber and 3 parts by weight of silicone leveling agent.

[0022] The preparation method of the above-mentioned non-yellowing anti-graffiti resin for synthetic leather is: under normal temperature and pressure, 45 parts by weight of DMF, 10 parts by weight of acetone, 3 parts by weight of dimethylsiloxane, 2 parts by weight of organic silicone oil, 1.5 parts by weight of Part of anti-graffiti additive, 0.5 part by weight of anti-ultraviolet absorber, and 3 parts by weight of silicone leveling agent are mixed, stirred for at least 30 minutes, then ground and filtered, and the filter residue is discarded...

Embodiment 2

[0025] 45 parts by weight of polyether polyurethane resin, 30 parts by weight of DMF, 20 parts by weight of acetone, 2 parts by weight of dimethylsiloxane, 1 part by weight of organic silicone oil, 2 parts by weight of anti-graffiti additive, 0.3 parts by weight of anti-ultraviolet absorber , 5 parts by weight of silicone leveling agent.

[0026] The preparation method of the above-mentioned non-yellowing anti-graffiti resin for synthetic leather is: under normal temperature and pressure, 30 parts by weight of DMF, 20 parts by weight of acetone, 2 parts by weight of dimethylsiloxane, 1 part by weight of organic silicone oil, 2 parts by weight of Part of anti-graffiti additive, 0.3 part by weight of anti-ultraviolet absorber, and 5 parts by weight of silicone leveling agent are mixed, stirred for at least 30 minutes, then ground and filtered, and the filter residue is discarded. Add 45 parts by weight of polyether polyurethane resin to the obtained mixture, filter after stirrin...

Embodiment 3

[0029] The non-yellowing anti-graffiti resin for synthetic leather consists of 40 parts by weight of polyether polyurethane resin, 40 parts by weight of DMF, 15 parts by weight of acetone, 4 parts by weight of dimethylsiloxane, 3 parts by weight of organic silicone oil, and 1 part by weight of anti-graffiti additive It is composed of 0.4 parts by weight of anti-ultraviolet absorber and 4 parts by weight of silicone leveling agent.

[0030] The preparation method of the above-mentioned non-yellowing anti-graffiti resin for synthetic leather is: under normal temperature and pressure, 40 parts by weight of DMF, 15 parts by weight of acetone, 4 parts by weight of dimethylsiloxane, 3 parts by weight of organic silicone oil, 1 part by weight of 1 part of anti-graffiti additive, 0.4 part by weight of anti-ultraviolet absorber, and 4 parts by weight of silicone leveling agent were mixed, stirred for at least 30 minutes, then ground and filtered, and the filter residue was discarded. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com