High-pressure hot-blowing deicing and snow removing vehicle

A technology of hot air blower and snow removal vehicle, applied in snow surface cleaning, cleaning method, construction and other directions, can solve the problems of expensive operation, inability to move, incomplete road cleaning, etc., achieve good social and economic benefits, and clean the road surface cleanly Completely improve the effect of flight punctuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

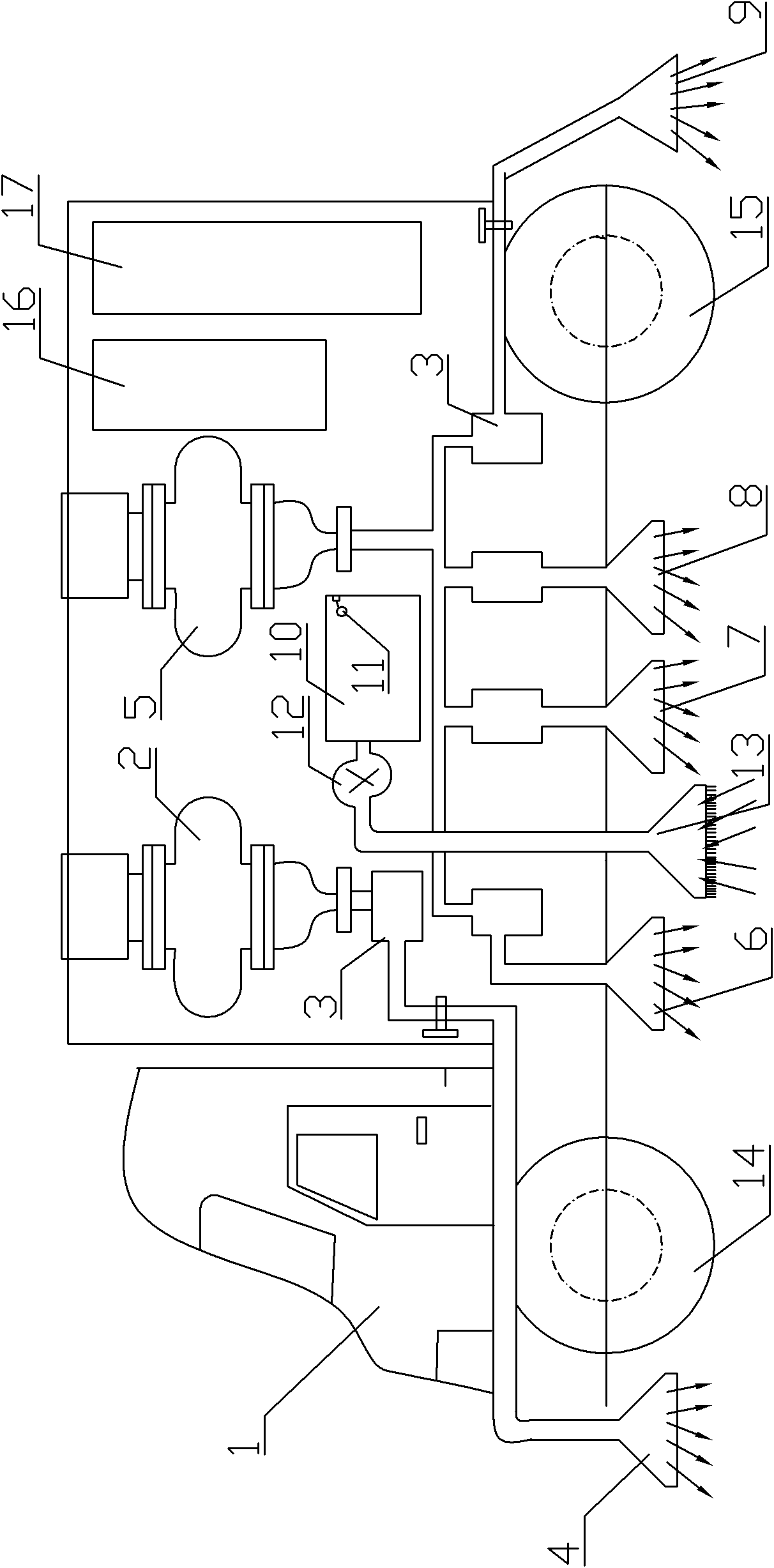

[0025] Refer to attached figure 1 :

[0026] The high-pressure hot air blowing type deicing and snow removal vehicle of the present invention includes a vehicle body, a cab 1, a high-pressure hot air snow-melting system, water and dust suction equipment, and a low-pressure drying system. In the middle of the car body, the low-pressure drying system is arranged at the rear of the car body, and the high-pressure hot air snow-melting system, water and dust suction equipment and low-pressure drying system are respectively connected with the electrical control cabinet 16 and the generator set 17. Generator set 17 adopts diesel generator set.

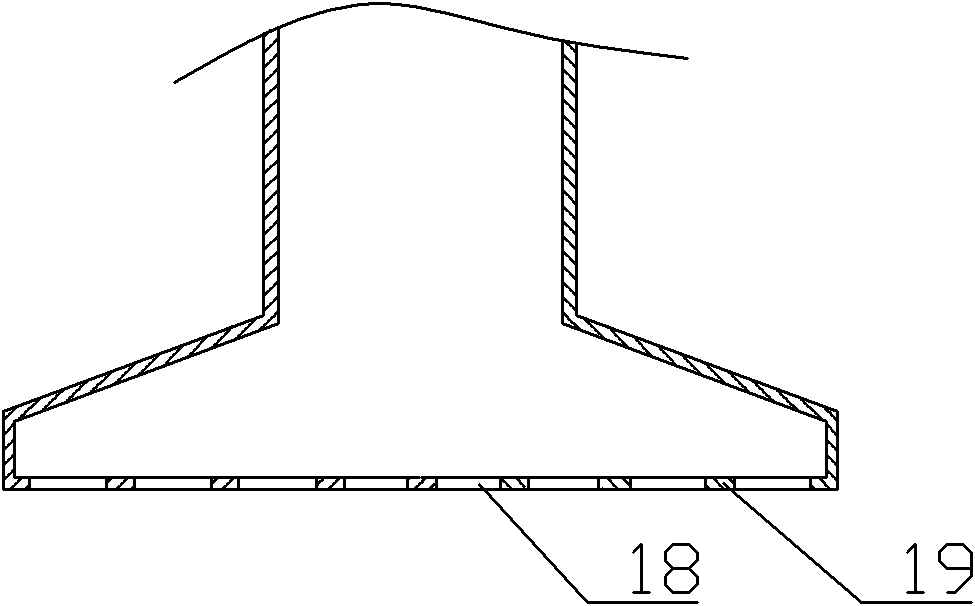

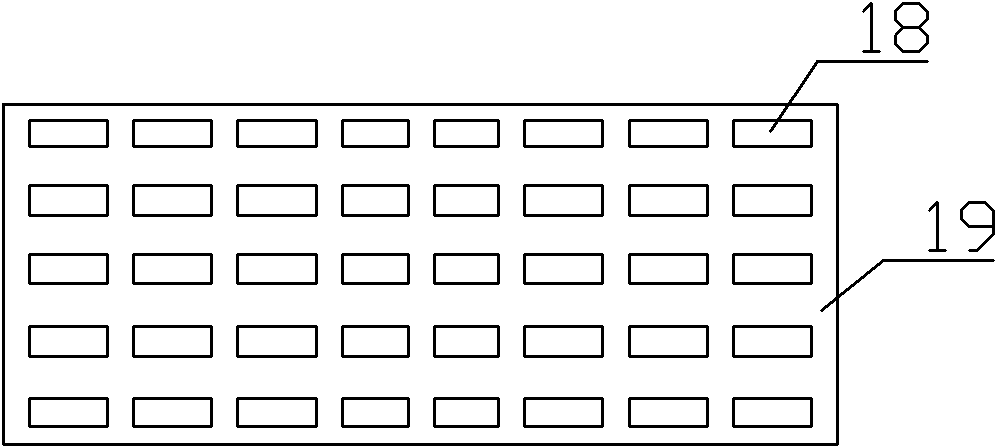

[0027] Wherein, the high-pressure hot air snow melting system includes a high-pressure blower 2 and a first air outlet 4 connected with the high-pressure blower 2, the first air outlet 4 is installed in front of the front wheel 14, and an air heater is installed on the pipeline connecting the high-pressure blower 2 and the first air outlet 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com