Valve core of throttle valve for petroleum drilling manifold

A choke manifold and oil drilling technology, which is applied in the field of choke valve cores used in oil drilling choke manifolds, can solve problems such as unstable liquid flow, large end surface contact area, and large opening and closing strokes, achieving Long service life, easy processing, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

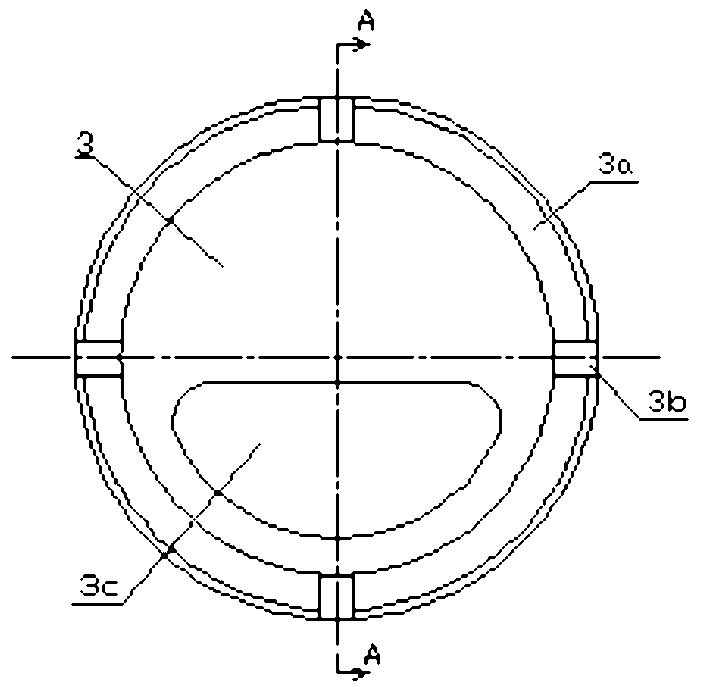

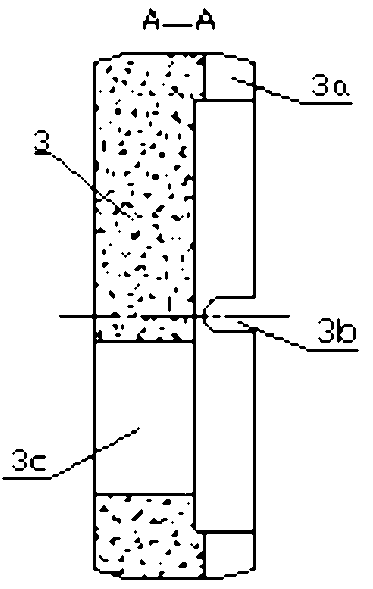

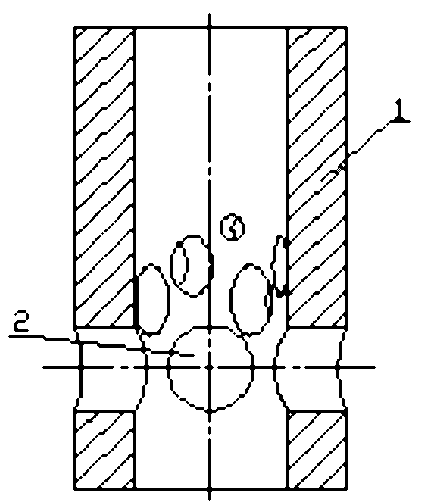

[0013] Depend on image 3 and Figure 4 As shown, the choke valve spool used for oil drilling choke manifold includes a cylindrical spool 1, and four groups of helically arranged choke holes are evenly distributed on the side wall of the spool 1, Each group of throttle holes includes four throttle holes 2, and the aperture diameter of each group of spirally arranged throttle holes 2 decreases sequentially from bottom to top, and each throttle hole 2 communicates with the inner hole of the valve core 1;

[0014] The spool 1 adopts a cylindrical structure, and the surface is easy to be ground, polished, and polished, and it is convenient to ensure the processing quality and achieve high matching accuracy; because the force on the circumference is uniform in all directions, the spool 1 will not be axially twisted in the valve seat. To run and run radially, and the gap i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com