Active control test platform and method for vibration of near space aircraft model

A near-space, active control technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems affecting aircraft short-period motion, instability, and failure to respond, and achieve easy vibration testing and vibration active control experiments , Easy installation and removal, and convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the scope expressed by the examples.

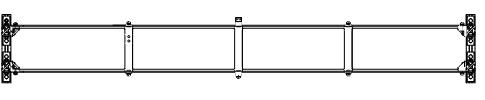

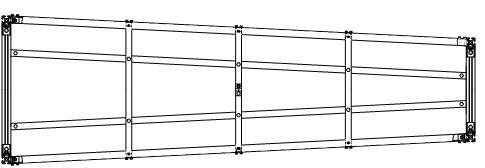

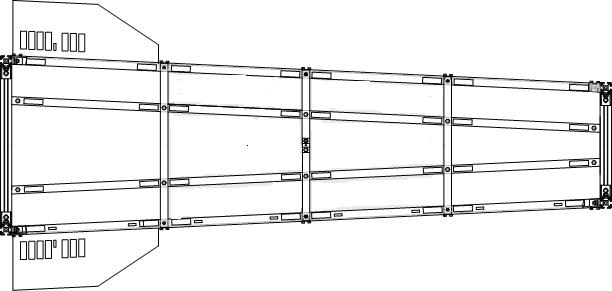

[0035] Such as image 3 As shown, the experimental platform for active vibration control of the near-space vehicle model includes an aluminum alloy outer frame ①, an aircraft model ② frame structure, a sensor network ③ containing multiple groups of piezoelectric sensors, and a set of sensor networks containing multiple groups of piezoelectric sensors. Actuation network of electric actuator ④, one exciter ⑤ (model: JZK-10, manufacturer: Jiangsu Lianeng Electronics Co., Ltd.), multiple piezoelectric drive power amplifiers ⑥ (model: PZT350, manufacturer: Shanghai University Automation Department), multiple charge amplifiers ⑦ (Model: YE5852A, manufacturer: Jiangsu Lianeng Electronics Co., Ltd.), a digital oscilloscope ⑧ (model: GDS-840C, manufacturer: Good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com