Shape appliance digitalizing method of cleft palate alveolar bone

A technology of alveolar bone and appliances, applied in the medical field, can solve the problem that the accuracy cannot meet the digital precision design of alveolar bone shaping appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

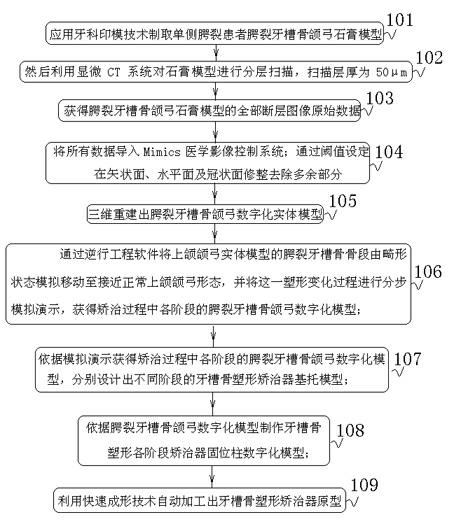

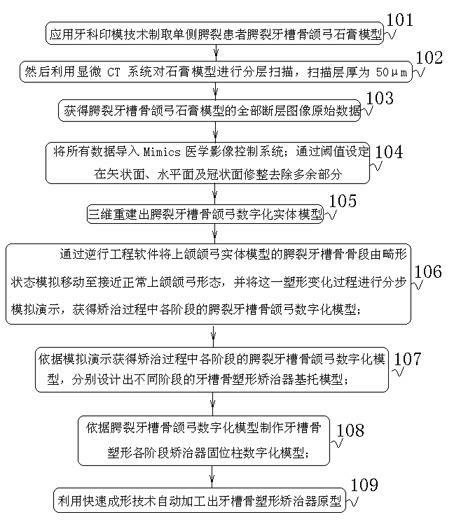

[0030] Such as figure 1 As shown, a digital method for cleft palate alveolar bone shaping appliance, at least includes the following steps:

[0031] Step 101, using dental impression technology to make a plaster model of the alveolar bone and jaw arch of patients with unilateral cleft palate;

[0032] Step 102, and then use the micro-CT system to scan the plaster model in layers, and the scanning layer thickness is 50 μm;

[0033] Step 103, obtaining the original data of all tomographic images of the plaster model of the cleft palate alveolar bone and maxillary arch;

[0034] Step 104, importing all data into the Mimics medical image control system; trimming and removing redundant parts on the sagittal plane, horizontal plane and coronal plane through threshold setting;

[0035] Step 105, three-dimensional reconstruction of the digital solid model of the cleft palate alveolar bone and jaw arch;

[0036] In step 106, the cleft palate alveolar bone segment of the maxillary ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com