Method and device for detecting knocking occurrence during switching process between operating modes of internal combustion engine

A technology of conversion process and internal combustion engine, which is applied in the field of knock recognition, and can solve the problems of not recognizing knock and wrongly identifying knock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

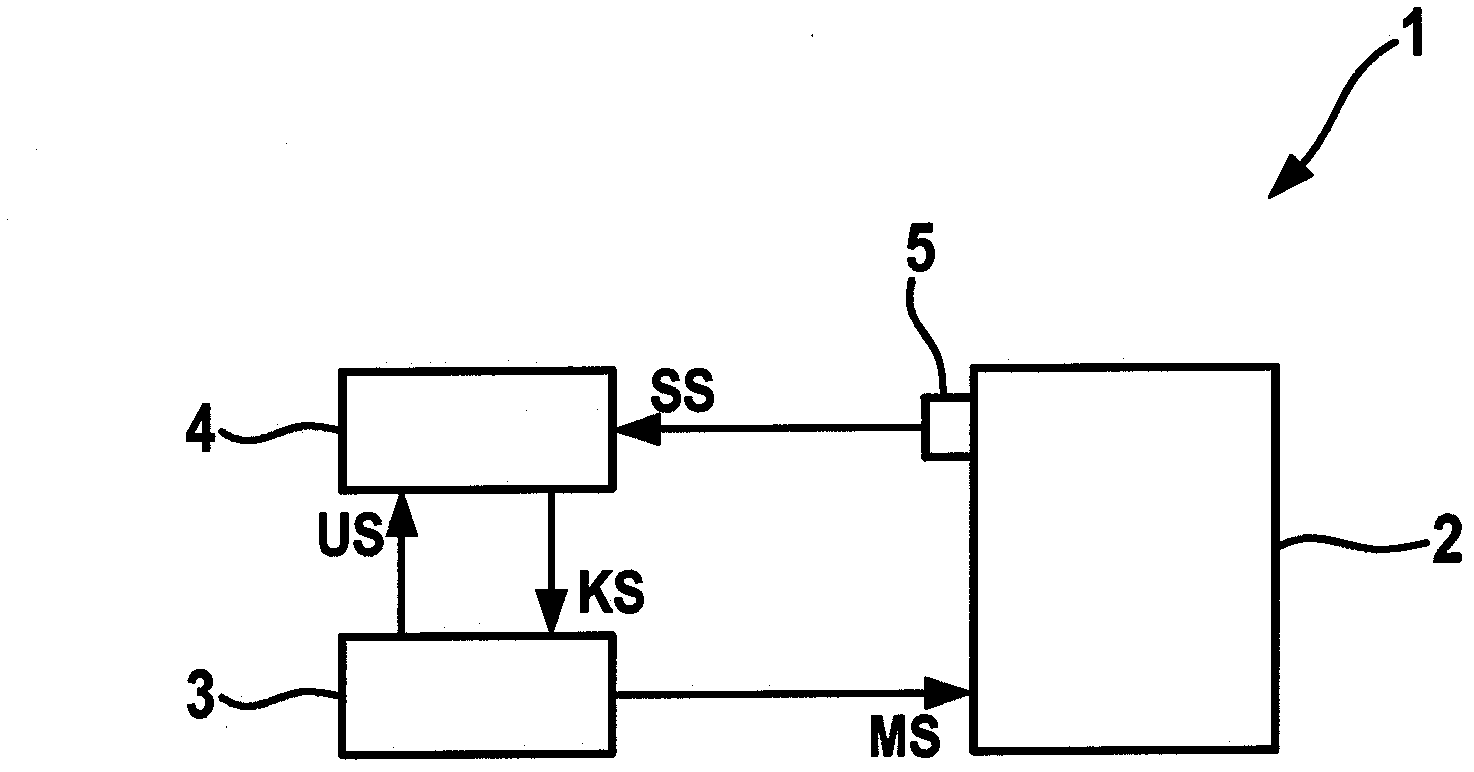

[0040] figure 1 An engine system 1 is shown with an internal combustion engine 2 , which is controlled by a control unit 3 . The control unit 3 is contained, for example, in a conventional engine controller and can control all or some of the functions required for operating the internal combustion engine 2 .

[0041] The internal combustion engine 2 is designed for operation with different fuel types, for example natural gas (CNG) or petrol, wherein the engine control unit 3 can adjust the operating mode automatically or manually (that is to say specified by the driver). The control unit 3 controls the internal combustion engine 2 with the aid of engine control signals MS, which can prescribe, for example, the throttle position, the injection quantity (for example by adjusting the opening and closing times of the injection valves), the ignition timing, etc.

[0042] In addition, a knock detection unit 4 is provided, which can receive the acoustic signal SS, for example in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com