High-accuracy automatic thickness control method and equipment based on thickness gauge subsection monitoring

A technology of automatic thickness control and thickness gauge, which is used in rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problem of large difference in rolling force, restrict thickness accuracy, and can not improve thickness hit rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1. A kind of automatic thickness control method based on thickness gauge section monitoring:

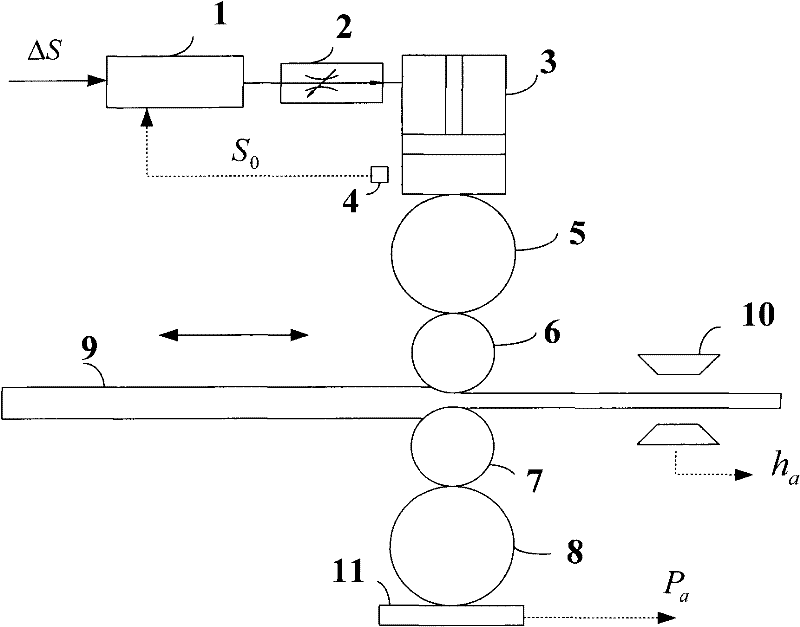

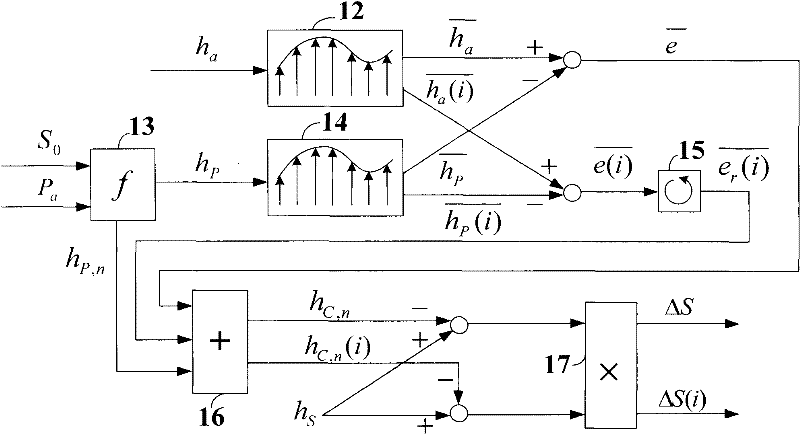

[0052] see figure 1 and figure 2 , the compensation method includes the following steps:

[0053] 1. Obtain the predicted thickness value h p and take the average of

[0054] During the rolling process, from the beginning of biting the steel to the steel throwing of this pass, calculate the predicted thickness, sample the predicted thickness and calculate the average value, specifically:

[0055] (1) Calculate the predicted thickness value from the process of biting steel in this pass until steel throwing.

[0056] Since the reversing rolling mill is rolled back and forth, and equipped with a thickness gauge, the thickness of the steel plate can only be measured in odd or even passes. The thickness of the steel plate can be measured in the pass of the thickness gauge, from the beginning of the steel bite of the rolling mill until the steel throwing of the ro...

Embodiment 2

[0091] Embodiment 2. Automatic thickness control equipment based on thickness gauge section monitoring:

[0092] The structure of the automatic thickness control device is as follows: figure 2 As shown, it includes a predicted thickness calculation device 13 , a sampling average device, an absolute thickness calculation device and an AGC adjustment device 17 which are sequentially connected by electrical signals.

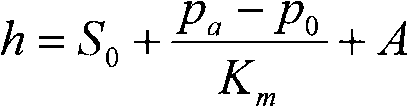

[0093] The predicted thickness calculation device 13 is a device used to calculate the predicted outlet thickness of the steel plate, which is realized by programming on a programmable logic controller, and which is calculated by the following formula:

[0094] h p = S 0 + p a - p 0 K m - T of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com