Method for manufacturing solid pine board

A technology of solid board and pine wood, which is applied in the jointing of wooden veneers, manufacturing tools, flat products, etc. It can solve the problems of poor strength and toughness, easy deformation of woodworking boards, poor corrosion resistance, etc., and achieve full and smooth lines. Beautiful color and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

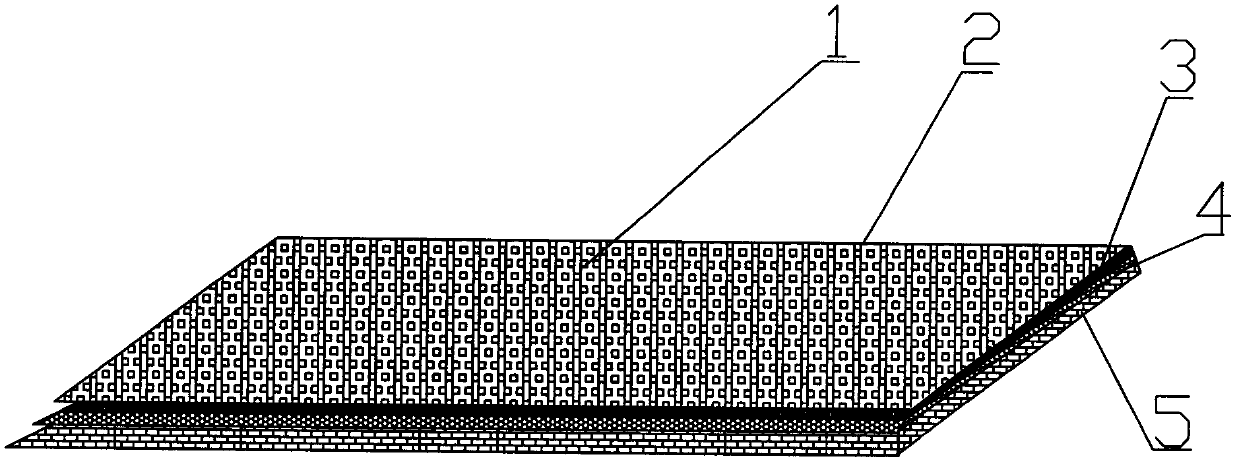

[0015] With reference to accompanying drawing, the present invention is made of pine veneer 2, poplar, Chinese fir, elm, linen, chemical fiber cloth, glass glue by a kind of pine plywood, concrete method steps are as follows: first poplar, Chinese fir, elm , the chemical fiber cloth is pulverized for later use; then the glass glue 4 is put into a heating tank to melt; the pulverized poplar, fir, elm, and chemical fiber cloth are put into the heating tank and mixed together with the glass glue 4, and put into a mold for pressing and forming , form the base board; the surface of the base board is coated with hot-melt glue, then the linen cloth 3 is covered on the hot-melt glue, and a layer of pine veneer 2 is covered on the hot-melt glue; uniformly pressed on the pine veneer 2 One layer of wear-resistant layer 1, and finally the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com