Method for manufacturing EVA (ethylene vinyl acetate copolymer) multi-color and multi-hardness sole

A production method and multi-hardness technology, applied in the field of sports shoes, can solve the problems of increasing production costs, increasing labor, and poor results, and achieve the effect of reducing material cost loss, reducing labor costs, and increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

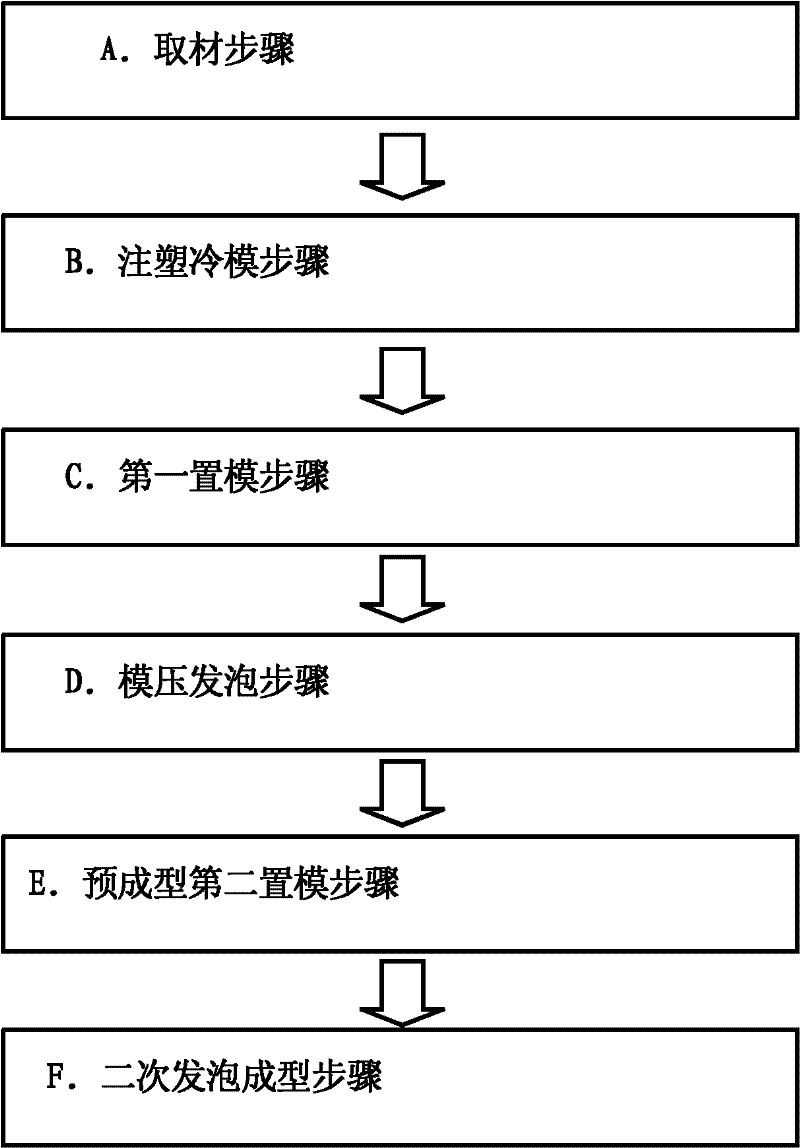

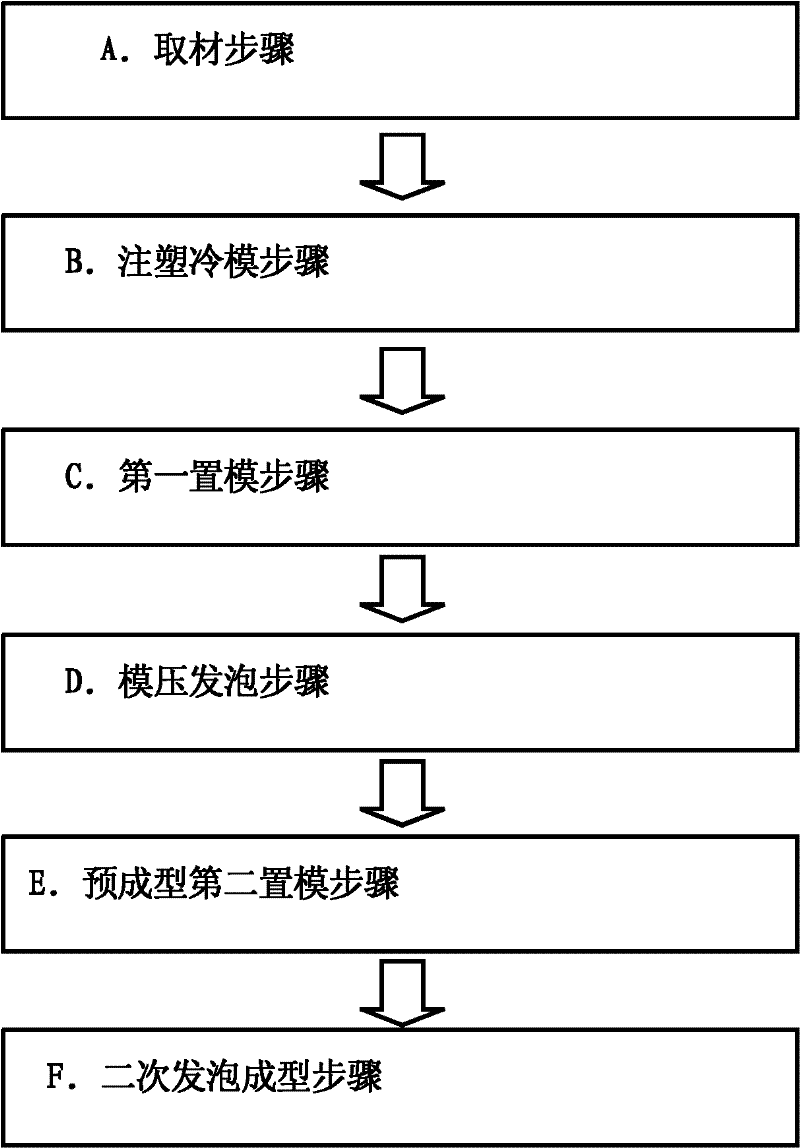

Method used

Image

Examples

Embodiment 1

[0028] A kind of three-color sole, the hardness of the side is greater than that of the middle sole. The red, yellow and blue EVA grains are poured into different injection chambers of the injection molding machine. The hardness of the red and yellow grains is greater than that of the blue grains, but the three colors The expansion ratio of the EVA particles is the same.

[0029] The blue EVA pellets are injected into the mold cavity in the center of the sole mold, and after the injection molding, the red EVA pellets and the yellow EVA pellets are respectively injected into the side parts of the sole in the sole mold; at the same time, the injection molded product is cooled to obtain Cold molded products, that is, cold molded products in which three colors coexist in the same sole mold.

[0030] Place the cold molded product of three-color injection in the mold cavity of the foaming mold, raise the temperature until the EVA particles start to foam, and maintain it until the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com