Preparation method of flexible carbon nanoparticle and application of method

A carbon nanoparticle, flexible technology, applied in the field of carbon nanoparticle preparation, can solve the problems of difficult synthesis and purification of carbon nanotubes, development obstacles, stability problems, etc., and achieve good field electron emission performance and good emission current stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for producing flexible carbon nanoparticles, used to generate a flexible carbon nanoparticle layer, the method comprises the steps of:

[0024] 1. Cut the carbon cloth to a size of 3cm×0.5cm, clean it and dry it with nitrogen gas for later use.

[0025] 2. Choose a ceramic sheet as the substrate, first ultrasonically clean it in acetone for 5 minutes, then ultrasonically clean it in absolute ethanol for 5 minutes, and finally ultrasonically clean it in deionized water for 5 minutes, and dry it with nitrogen gas for later use.

[0026] 3. Select the alcohol burned by the alcohol lamp as the carbon source of carbon nanoparticles, place the alcohol lamp in an environment without strong air convection, and light the alcohol lamp for standby.

[0027] 4. After the alcohol lamp burns for 10-15 minutes, place the carbon cloth at a distance of 5.5cm from the wick of the alcohol lamp.

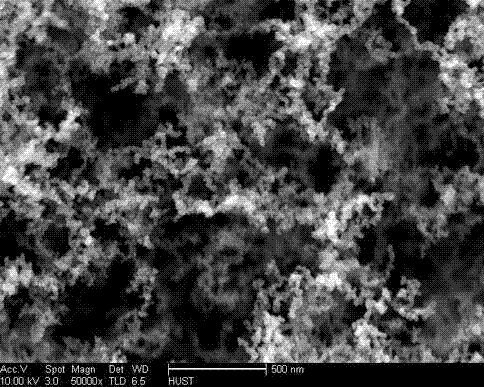

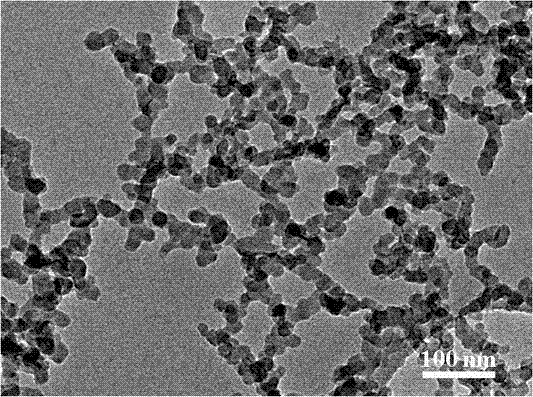

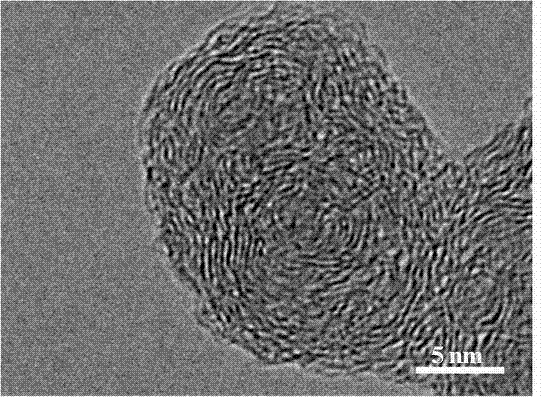

[0028] 5. After 30 seconds to 5 minutes, the carbon cloth is removed, and the carbo...

Embodiment 2

[0030] A method for producing flexible carbon nanoparticles, used to generate a flexible carbon nanoparticle layer, the method comprises the steps of:

[0031] 1. Cut the silicon wafer into 4cm×0.7cm size, ultrasonicate with acetone, alcohol and deionized water for 5 minutes each, and blow dry with nitrogen for later use.

[0032] 2. Choose a silicon wafer as the substrate, first ultrasonically clean it in acetone for 5 minutes, then ultrasonically clean it in absolute ethanol for 5 minutes, and finally ultrasonically clean it in deionized water for 5 minutes, and dry it with nitrogen for later use.

[0033] 3. Select the alcohol burned by the alcohol lamp as the carbon source of carbon nanoparticles, place the alcohol lamp in an environment without strong air convection, and light the alcohol lamp for standby.

[0034] 4. After the alcohol lamp burns for 10-15 minutes, place the silicon wafer at a distance of 5.5cm from the wick of the alcohol lamp.

[0035] 5. Remove the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com