Roof for sun room or canopy

A technology for sun room and tent, which is applied to roofs, roofs, roof coverings and other directions using flat/curved panels, can solve the problems of low manufacturing efficiency, water leakage of glass sheets, and high cost, achieves easy installation, avoids water leakage, reduces The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

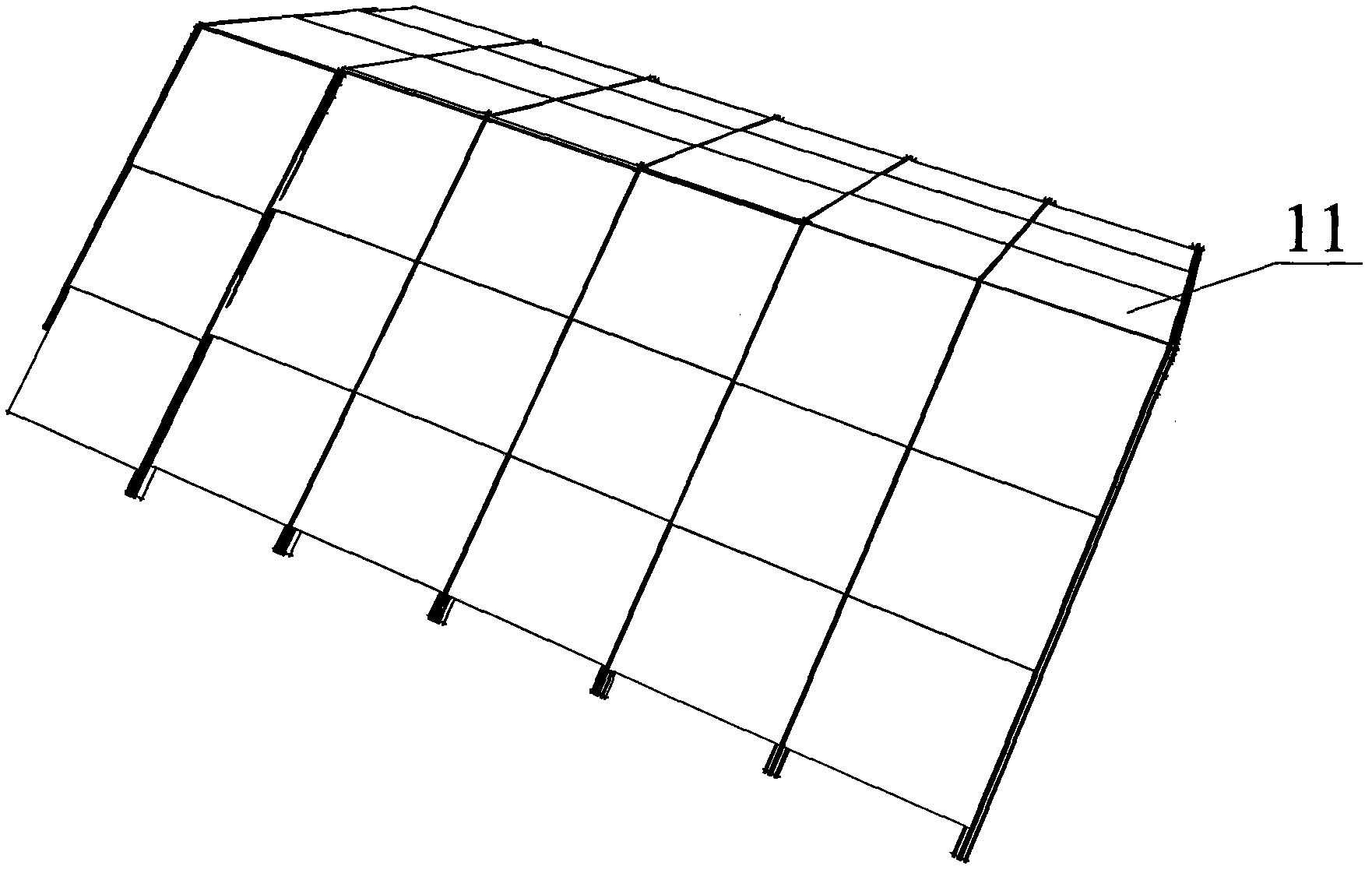

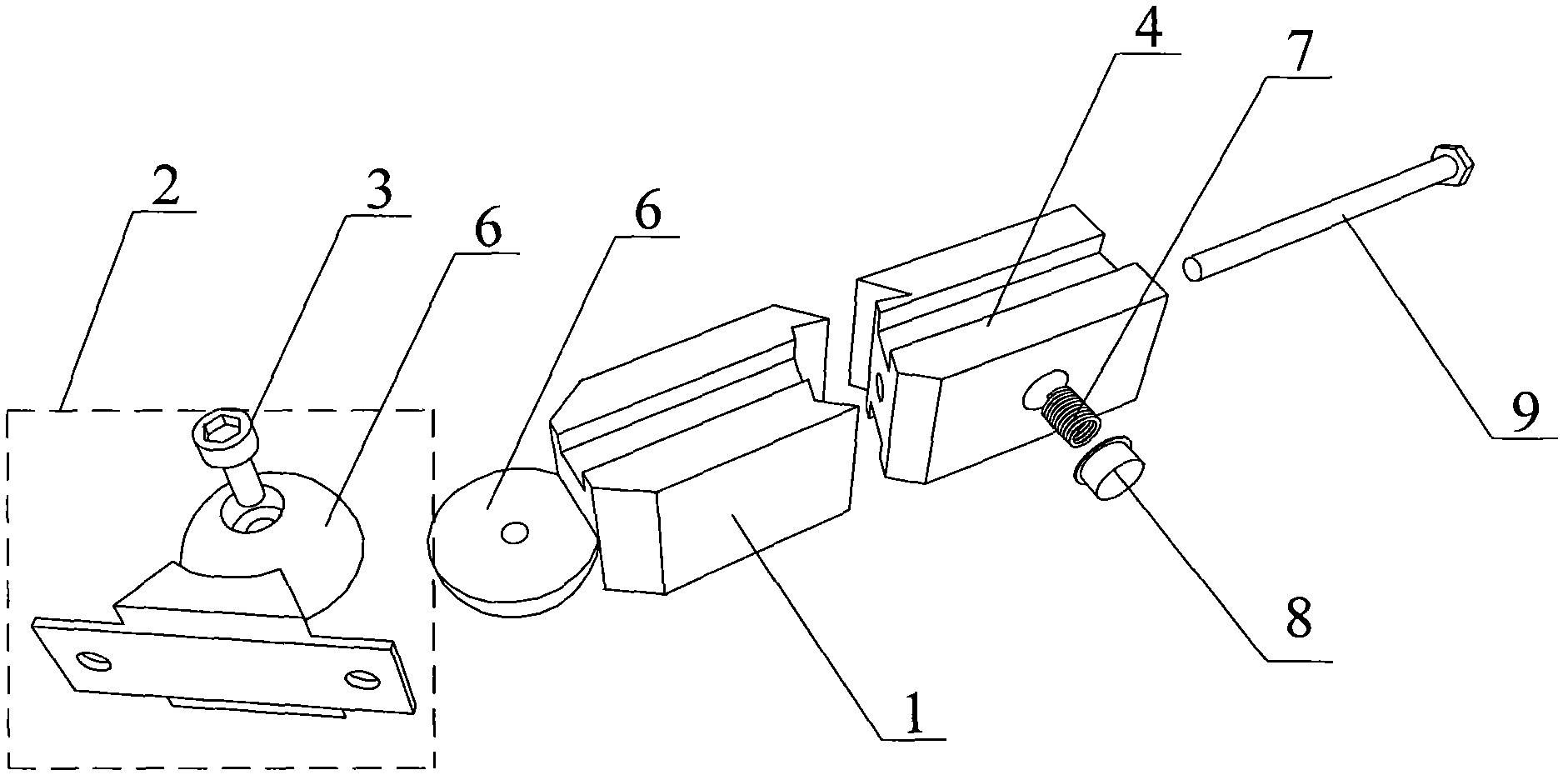

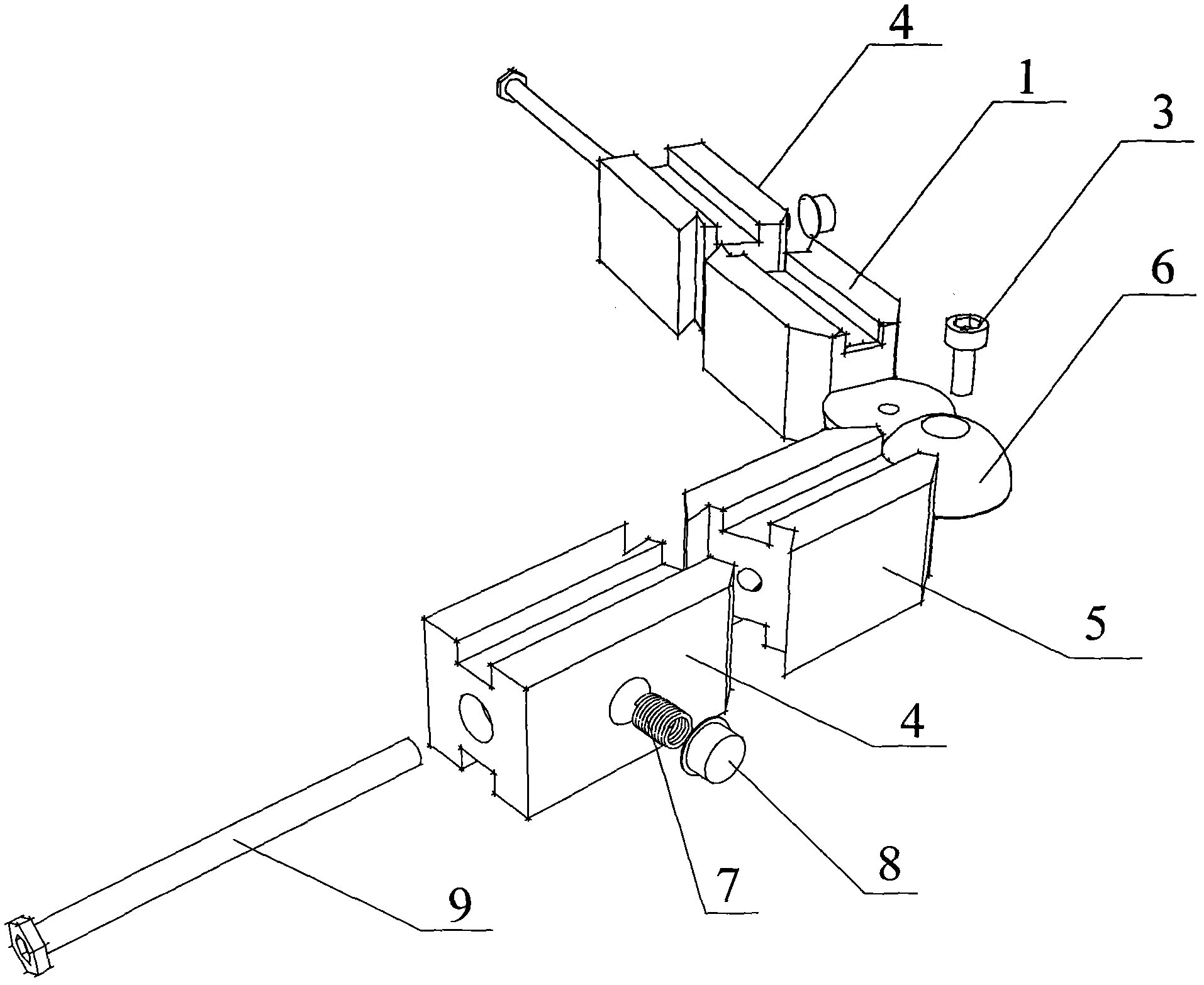

[0029] Such as figure 1 As shown, the roof of the present invention is mainly composed of more than two connecting members arranged parallel to each other, and a light-transmitting component is fixed between every two adjacent connecting members. Such as figure 2 As shown, each connecting member is composed of a connecting end 2 and a spar 1 in a bar-like structure in a hinged manner. That is, a hinged end 6 is provided at one end of the spar 1 and the connecting end 2, and the two hinged ends 6 are overlapped with each other and then hinged by the main screw 3 to ensure that the connection between the connecting end 2 and the spar 1 is fixed. The angle between them can be adjusted arbitrarily. According to needs, the hinged end 6 can be a separate part, and can also be integrally formed with the spar 1 and the connecting end 2 .

[0030] In order to meet the needs of different occasions, the connecting end 2 of this embodiment is realized by a common fixing piece, that is...

Embodiment 2

[0041] Compared with Embodiment 1, this embodiment has the same overall structure, the only difference is that the connection end 2 is not realized by a fixing piece, but by an auxiliary spar 5 whose shape and size are exactly the same as that of the spar 1. implementation, whose structure is as figure 2 shown.

[0042] Correspondingly, when the auxiliary spar 5 is used as the connecting end 2 , the connecting piece 4 is also connected to the other end of the auxiliary spar 5 through a connecting screw 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com