Pulse detonation engine with ejector and method for processing main detonation tube

A technology of pulse detonation and ejector, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as uneven heat transfer and poor fluidity, achieve good ejection effect, improve thermal fatigue life, The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

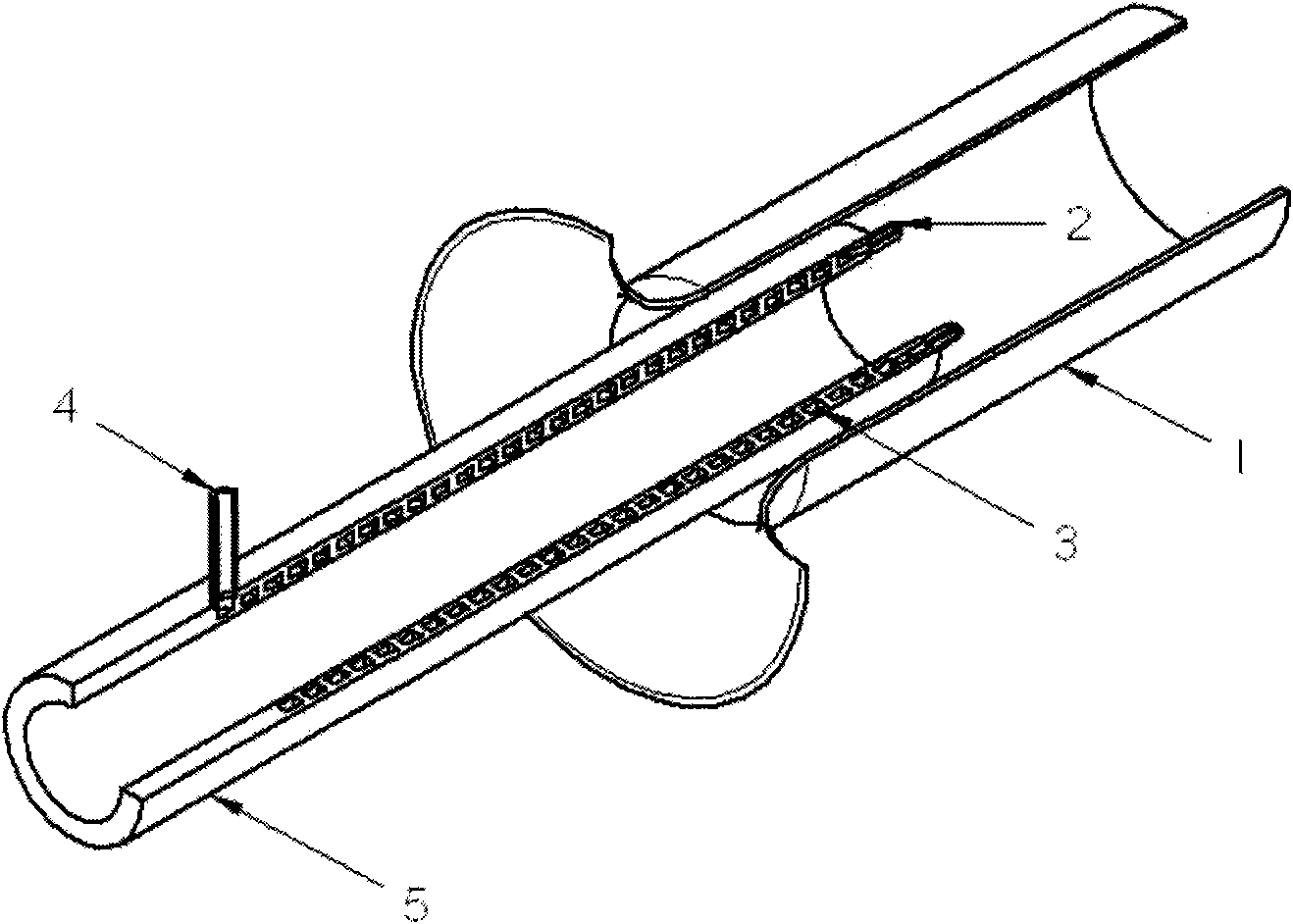

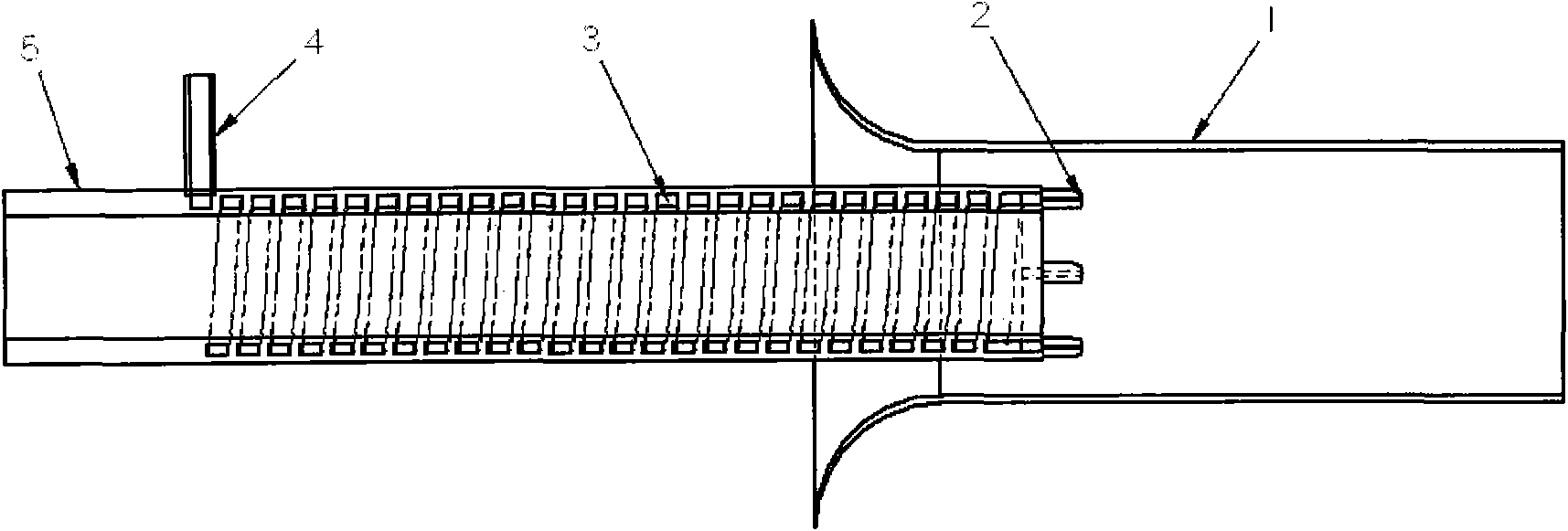

[0021] Refer to attached figure 1 And attached figure 2 , This embodiment includes an ejector 1, a fuel nozzle 2, a spiral channel 3, an oil inlet nozzle 4 and a main detonation tube 5.

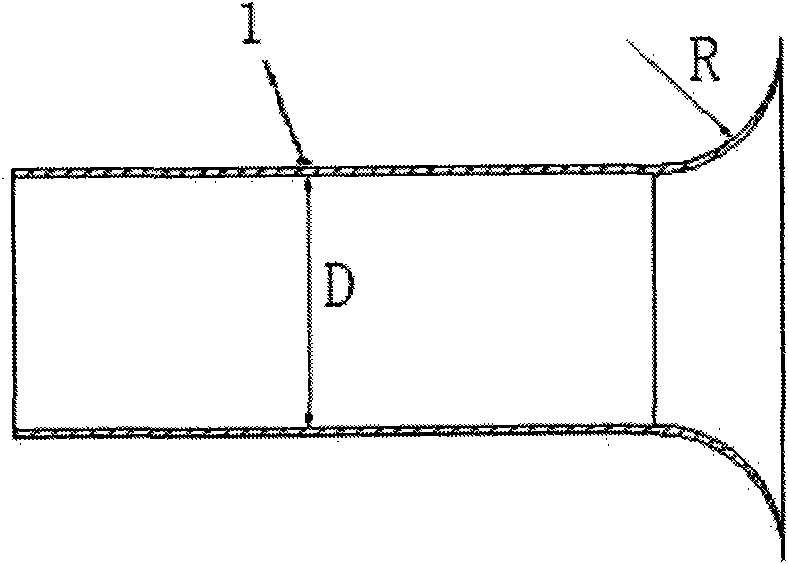

[0022] Refer to attached image 3 , One end of the inlet of ejector 1 is a trumpet-shaped expansion section, and the rest is a cylindrical section. The wall surface of the expansion section is a 1 / 4 arc wall surface, and the relationship between the arc radius R and the inner diameter D of the cylindrical section is R / D=0.5. Refer to attached figure 2 , the ejector 1 is coaxially installed with the main detonation tube 5; the requirements for the inner diameter D of the cylindrical section of the ejector 1 must firstly provide a sufficient area for ejecting the secondary flow, and secondly ensure that the inside of the ejector 1 is in contact with the outside world Therefore, in this embodiment, the relationship between the inner diameter d of the main detonation tube 5 and the inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com