Carbon nanotube film three-electrode gas temperature sensor and temperature measuring method thereof

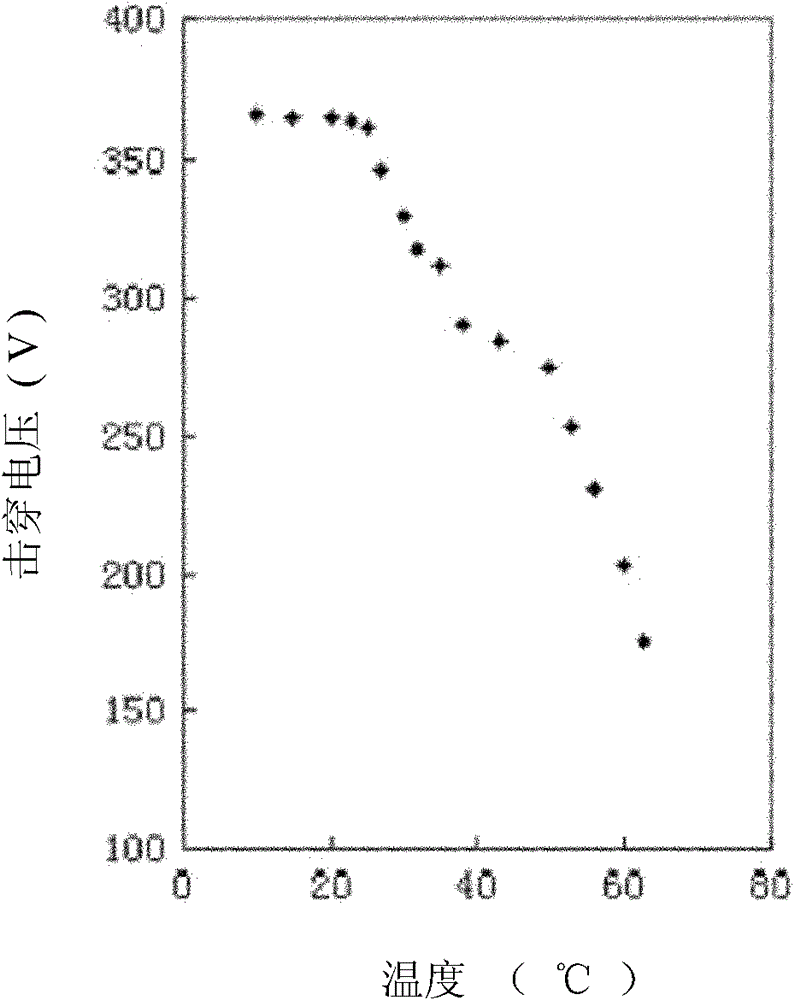

A technology of carbon nanotube film and gas temperature, applied in thermometers, thermometers with directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the problem of no temperature sensor, high working voltage, up to 360 volts, and temperature of At 60 degrees Celsius, the breakdown voltage is also above 150 volts, etc., to achieve accurate measurement and wide temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

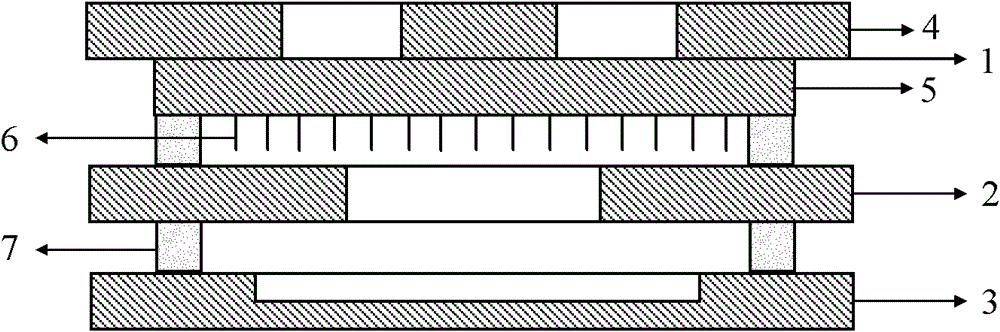

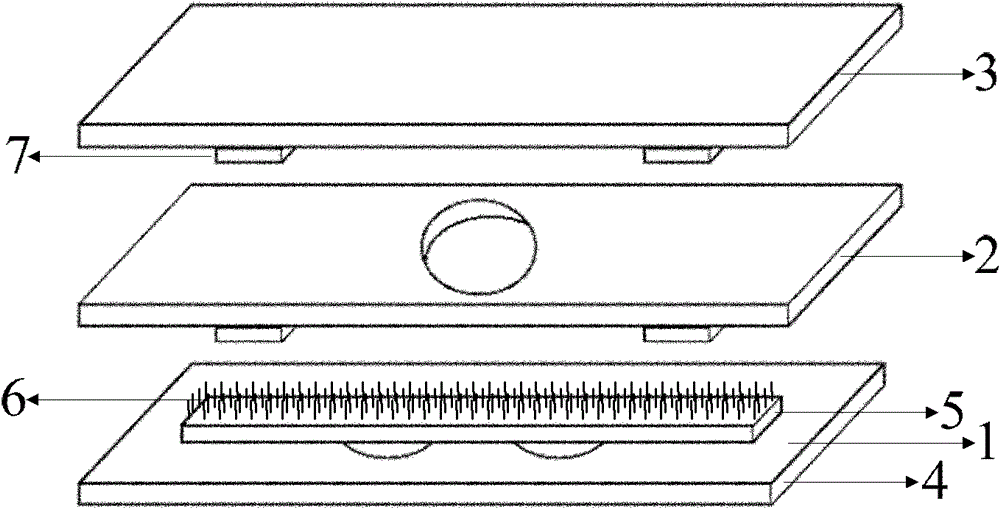

[0035] Such as figure 2 , image 3 As shown, the carbon nanotube thin film three-electrode gas temperature sensor consists of three electrodes stacked one after the other from top to bottom. The three stacked electrodes are respectively provided with a first electrode 1, a second electrode 2 and a third electrode. Electrode 3, the first electrode 1 of which is composed of a substrate 5 with a carbon nanotube film distributed on the inner surface and an electrode 4 with air holes; the second electrode 2 is composed of a lead-out plate with a lead-out hole in the center; The third electrode 3 is composed of a collector with a blind hole on the electrode plate surface; the three electrodes are separated from each other by insulating pillars 7 .

[0036] figure 2 In the shown embodiment of the carbon nanotube thin film three-electrode gas temperature sensor, there are two vent holes on the electrode surface of the first electrode 1, and the vent holes are circular; carbon nano...

Embodiment 2

[0044] The basic structure of the sensor of this embodiment is the same as that of Embodiment 1, the difference is:

[0045] Among the three electrodes of the carbon nanotube film three-electrode gas temperature sensor, the electrode spacing between two adjacent electrodes is fixed at 170 μm, the first electrode 1 has two vent holes, the second electrode 2 has one lead-out hole, and the third There is one blind hole for the electrode 3 .

[0046] Using the carbon nanotube film three-electrode gas temperature sensor with fixed electrode spacing, the single-value temperature characteristics in nitrogen were obtained experimentally ( Figure 5 Shown), the temperature measurement model established by the fusion of the ion current input data output by the sensor, and the temperature measurement value in nitrogen with an accuracy of less than 1% is obtained.

[0047] Figure 5 In the embodiment shown in which the carbon nanotube film three-electrode gas temperature sensor measures...

Embodiment 3

[0049] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the electrode spacing between two adjacent electrodes in the three electrodes of the carbon nanotube film three-electrode gas temperature sensor is 250 μm and 30 μm respectively, and the first electrode 1 and the second electrode The area of two electrodes and two plates facing each other is 0.01mm 2 , the area of the plate facing the second electrode 2 and the third electrode 3 is 0.01mm 2 .

[0050] There is one vent hole on the electrode surface of the first electrode 1, and the vent hole is quadrilateral, pentagonal or hexagonal; the second electrode 2 has 4 center lead-out holes, and the lead-out holes are quadrilateral, pentagonal or hexagonal ; The number of blind holes in the third electrode 3 is 4, and the blind holes are 3-6 prisms or pyramids.

[0051] The temperature measuring method of the present embodiment is basically the same as embodiment 1, the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com