Method for realizing order analysis of rotating machinery

A technology of order analysis and implementation method, applied in the field of signal processing, can solve problems such as high difficulty, high cost of frequency multiplier, and reduced system reliability, so as to reduce production cost, reduce cost and installation difficulty, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

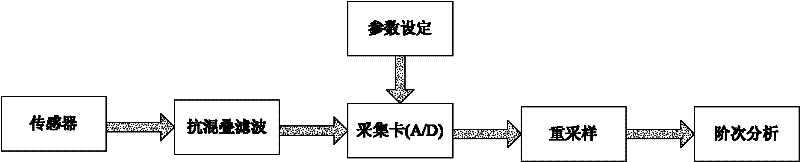

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

[0024] 1) Round the transmission ratio m (one is not an integer, such as 3.24) to get n.

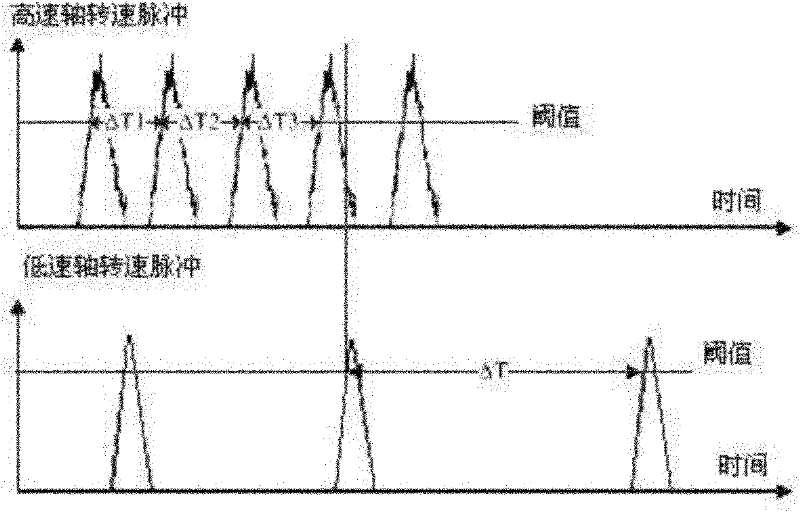

[0025] 2) Acquire the number of n pulses on the existing high-speed axis.

[0026] 3) Calculate the time interval between n pulse numbers (ΔT 1 ΔT 2 . . . ΔT n ).

[0027] 4) Calculate the pulse interval ΔT of the low-speed shaft according to the following formula, ΔT = m × Δ T 1 + Δ T 2 + · · · + Δ T n n

[0028] 5) Generate a new low-speed shaft pulse according to the ΔT obtained from the above calculation.

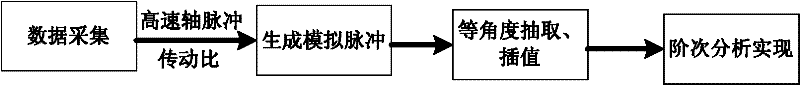

[0029] 6) According to the obtained analog pulse a...

Embodiment 2

[0032] This method is applied to the on-site work equipment of a high-line finishing mill in a steel plant in Tangshan. The on-site transmission gearbox is divided into three stages, and the transmission ratios are 5.16 and 2.54 respectively. Since the speed sensor is only installed on the shaft end of the motor, the other part of the gearbox The two output shaft ends are not equipped with rotational speed sensors, and n and m obtained by the order analysis technology proposed by the present invention are respectively 5.16, 2.54 and 5, 2. If there is no technology provided by the present invention, the gearbox can only be processed Reinstalling the sensor greatly increases the cost, and the application of the present invention still completes the task of order analysis without modification.

Embodiment 3

[0034] The deceleration gearbox in a precision forging workshop of a forging steel plant in Fushun monitors its state. According to the new technology of order analysis provided by the present invention, only a speed sensor needs to be installed at the motor end, and the transmission ratio of the gearbox is 4.56, and n is obtained. m are 4.56 and 4 respectively, according to this parameter and the speed pulse at the motor end, the analog pulse at the output end can be generated, and finally the order analysis of the gearbox can be realized.

[0035] Aiming at the shortcomings of relying too much on the rotational speed pulse in the implementation process of traditional order analysis, the present invention proposes an order analysis technology based on analog pulses. This technology can not only perform order analysis on equipment well, but also does not require Both ends are equipped with speed sensors, which reduces the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com