Automatic sampling device of bucket-type lifter

A bucket elevator and automatic sampling technology, which is applied in the direction of sampling devices, etc., can solve the problems of high labor intensity, unsafe and poor accuracy of manual coal sampling by bucket elevator, so as to reduce labor intensity, save manpower, improve representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

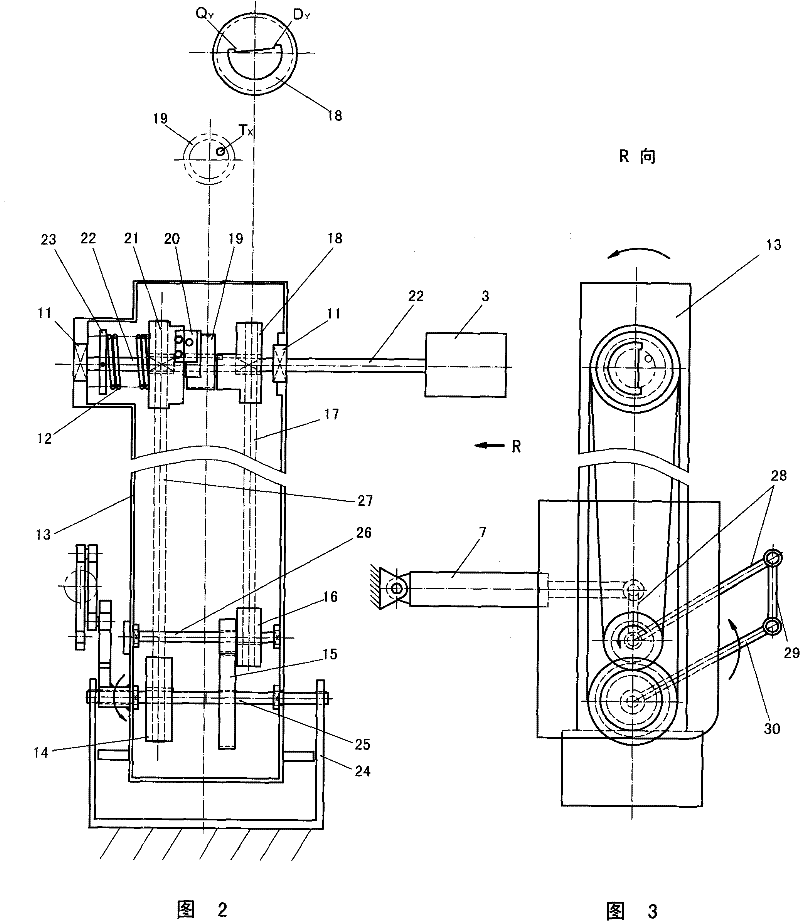

[0027] Since the automatic sampling device of the bucket elevator is installed in the discharge chute of the bucket elevator, the external dimensions are limited. In addition, it should be easy to remove and not affect the maintenance of the bucket elevator. Therefore, each part of the sampling machine is connected by a shaft or a hinge to facilitate disassembly and installation.

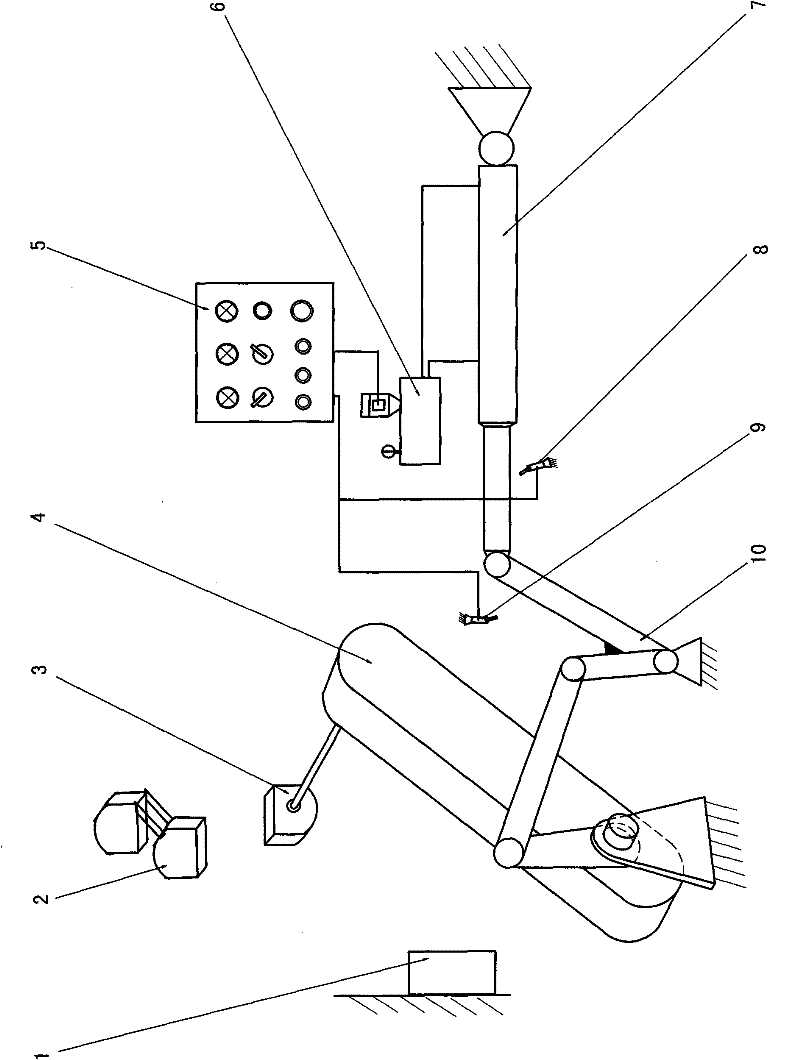

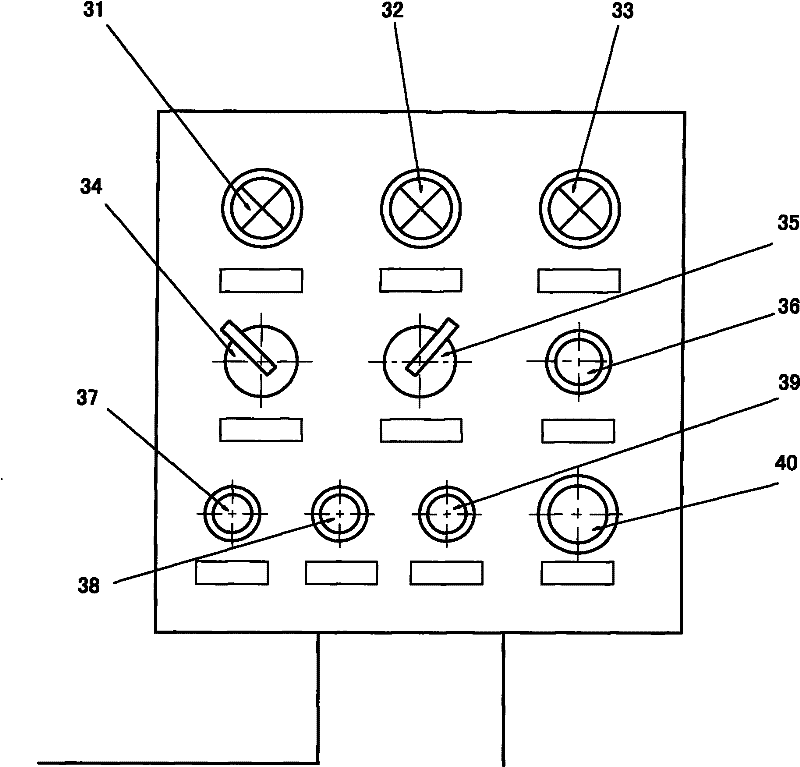

[0028] exist figure 1 The overall structure of the bucket elevator automatic sampling device of the present invention is shown. Bucket elevator automatic sampling device, referred to as bucket sampling machine. It is mainly composed of a sampling mechanism, a hydraulic push rod 7 and its hydraulic pump station 6, and a PLC control system. The sampling mechanism is mainly composed of a transmission link 10, a sampling arm transmission mechanism 4, a sampling hopper 3 and a hopper 1. Hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com