Method for predicting yield of coal tar

A prediction method and technology of tar yield, applied in the field of coal chemical industry, can solve the problems of low accuracy and achieve the effect of strong practicality and pertinence, optimization of coal blending structure, and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

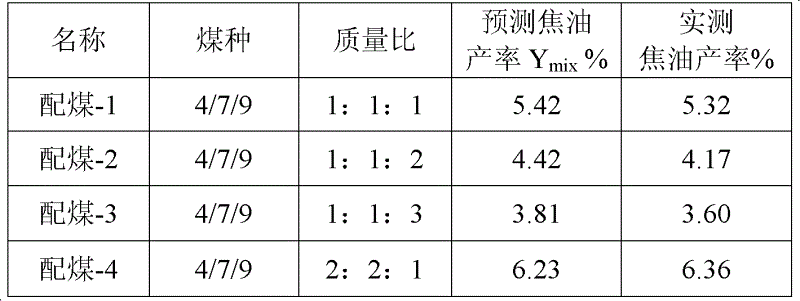

Examples

Embodiment Construction

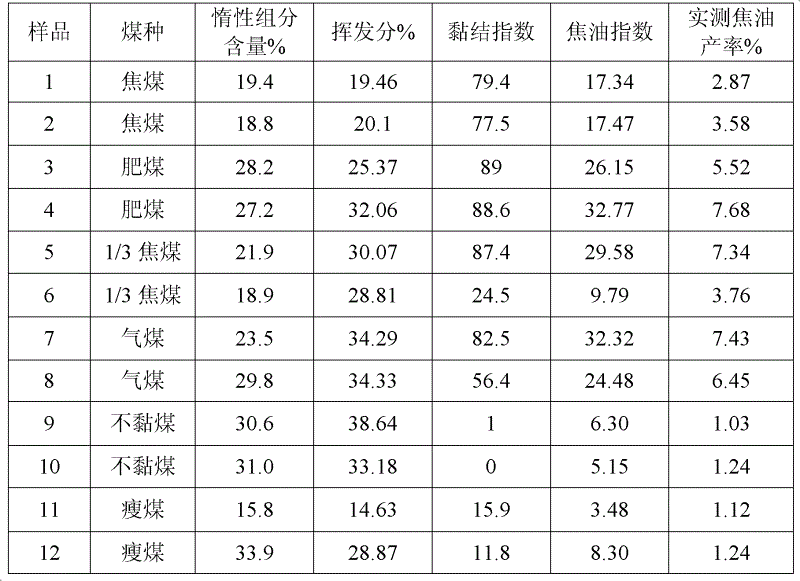

[0029] 1 Single coal experiment

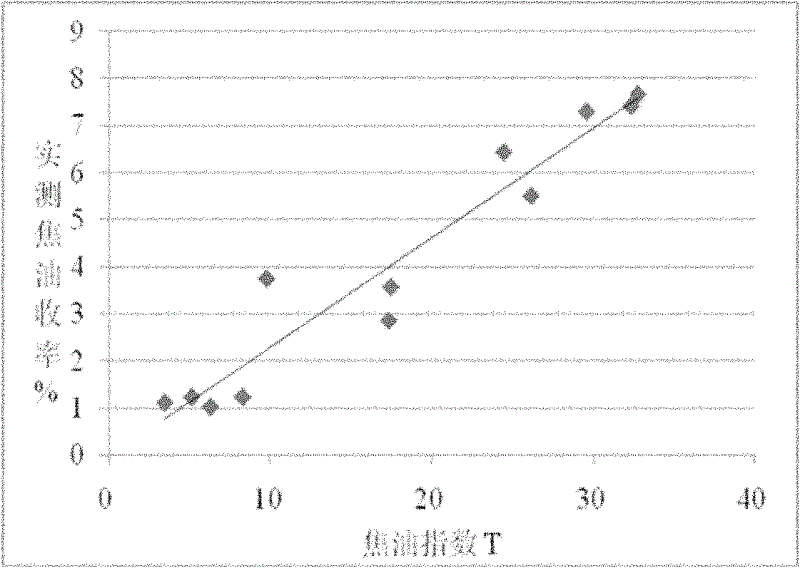

[0030] This experiment selects the coking coal types commonly used in various coking plants of Shougang at present, involving six different coal types of coking coal, 1 / 3 coking coal, fat coal, gas coal, lean coal and weakly caking coal, and chooses 2 for each coal type Samples, a total of 12 coal samples for heating experiments. The heating experiment conditions are as follows: in a nitrogen atmosphere, the coal sample is heated from room temperature to 800°C for 3 hours, the resulting coal gas is condensed with ice water to obtain tar, and the tar yield of each sample is calculated after removing the water in it. The volatile matter, cohesion index, and inert component content of each sample were determined according to national standards, and the test conditions of all samples were consistent. The tar index is according to the formula T=(AG+B∑I)×V daf ×100% calculated. Under the conditions of this experiment, A=1, B=0.5.

[0031] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com