Coke furnace temperature predicting method based on dynamic working conditions in coke furnace heating and burning process

A combustion process and prediction method technology, applied in the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc., can solve problems such as model difficulties, model online update difficulties, and changing working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

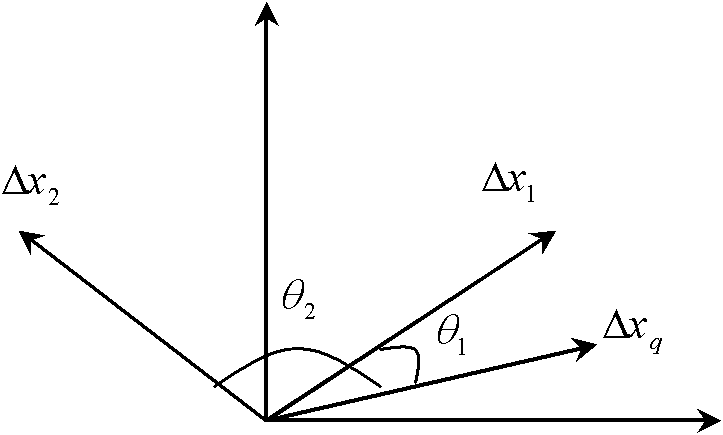

Method used

Image

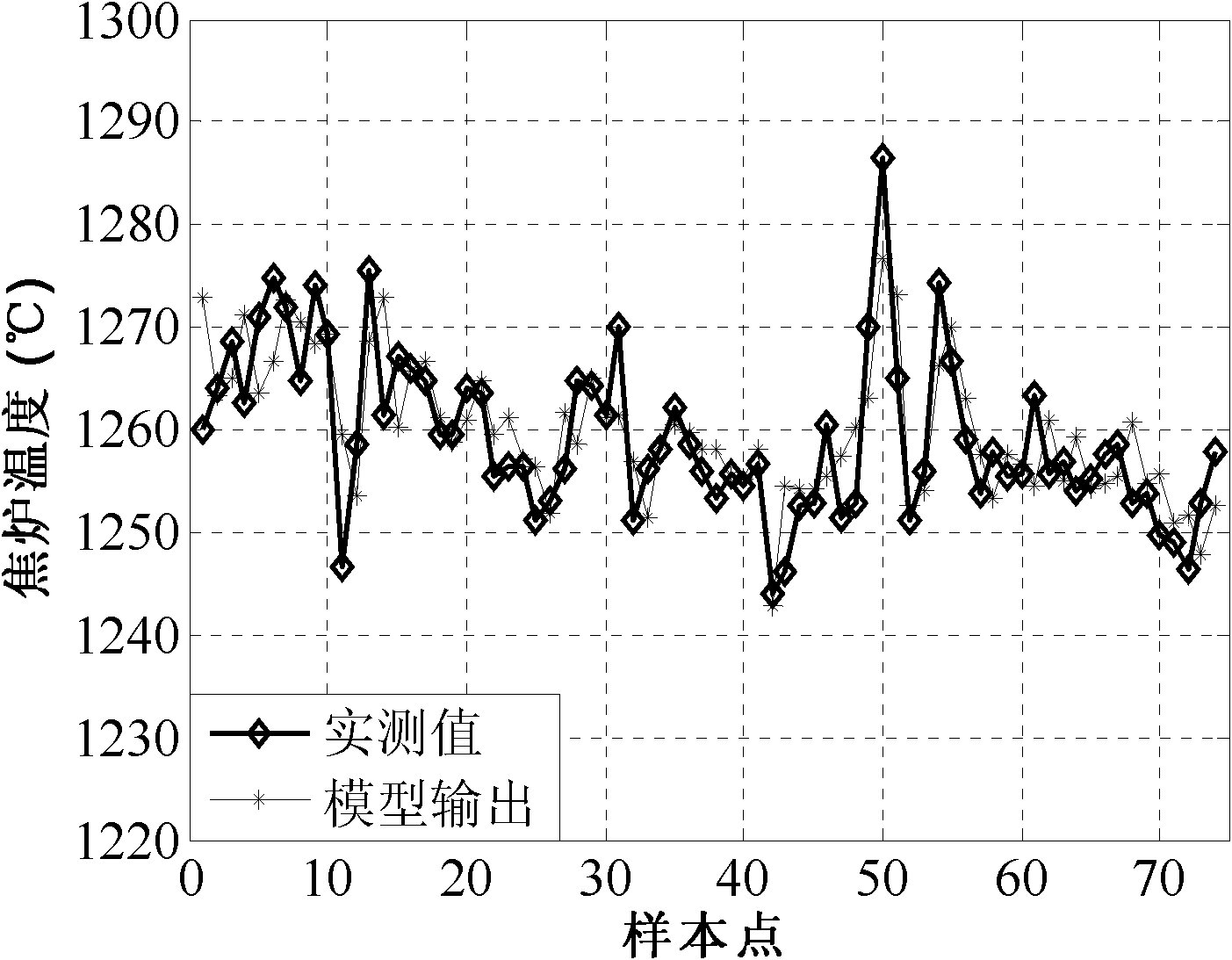

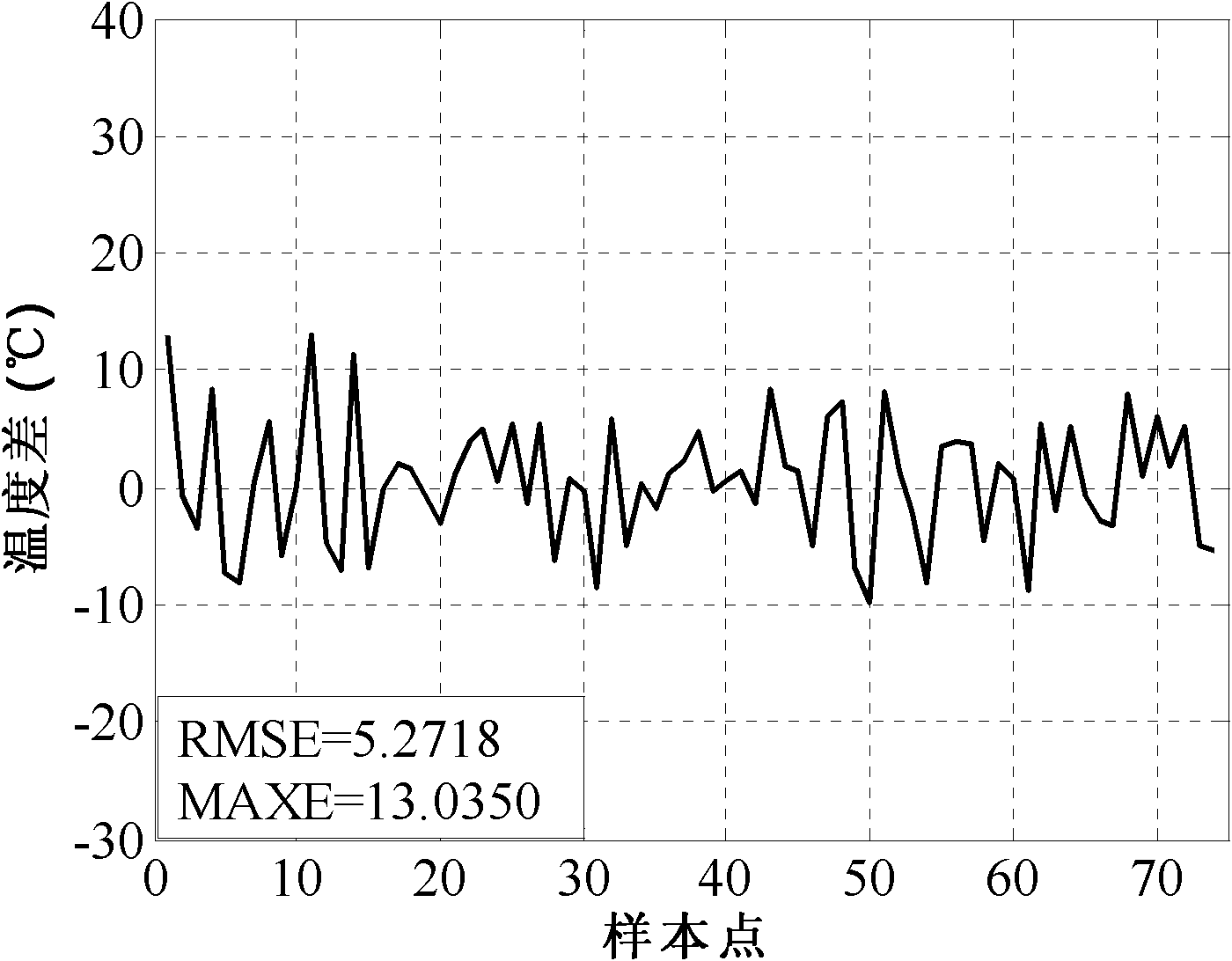

Examples

Embodiment 1

[0030] The main body of the coke oven is generally composed of 50-100 heating units. Each heating unit includes a carbonization chamber, a combustion chamber and a regenerator. The carbonization chamber and the combustion chamber are separated by a wall. The carbonization chamber is the place where the coal is isolated from the air for dry distillation, and the combustion chamber is the place where the gas is burned. Each combustion chamber also includes a certain number of vertical fire passages, wherein every two vertical fire passages are used as a pair to form a gas passage, and its two ends are respectively connected with the regenerator. The heating gas and air are mixed and burned in the fire channel of the combustion chamber to generate heat. The hot exhaust gas is mainly radiative heat transfer at high temperature, accompanied by convective heat transfer, and the heat is conducted to the coal material in the coalification chamber through the furnace wall. .

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com