Preparation method of spherical-crown transmitting transducer with high frequency and wide wave beam

A technology of transmitting transducers and spherical caps, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the manufacturing cost and difficulty High, prone to side shift, deformation and other problems, to achieve the effect of large beam width and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

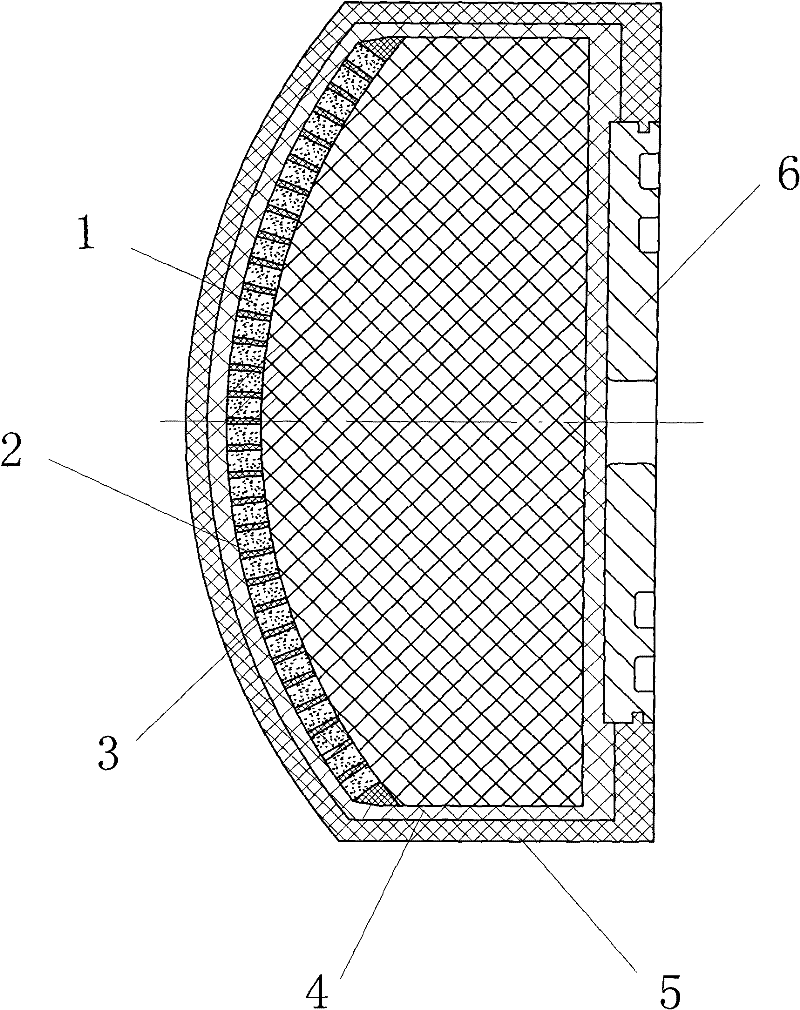

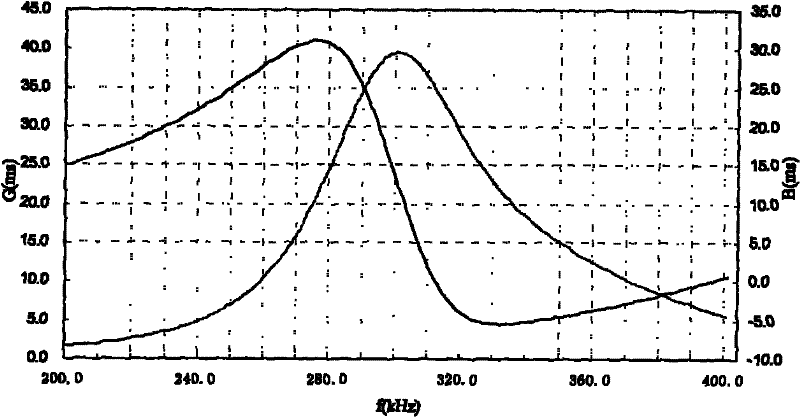

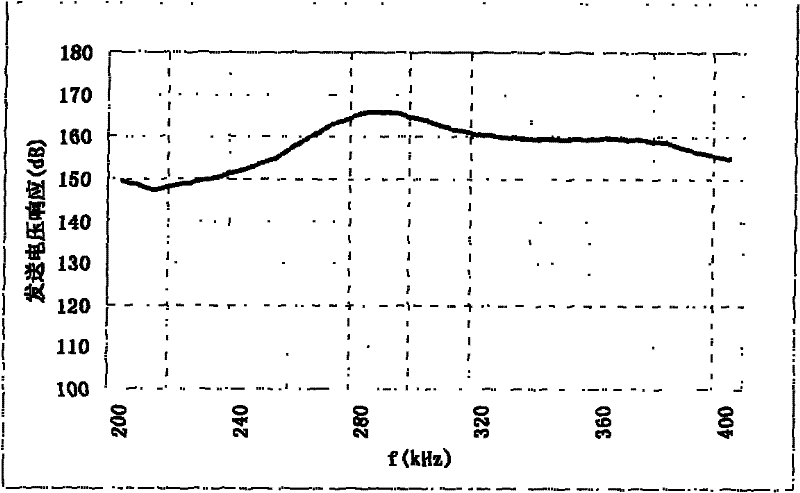

[0017] The present invention presents a spherical crown-shaped high-frequency and wide-beam high-power transducer, which adopts the front matching layer and the back lining technology, uses the spherical crown-type array first, and then fills it with polymer, thereby obtaining a square sound radiation area . The working frequency of the transducer is 300kHz. Through analysis and experiments, the optimal curvature radius and size of the spherical cap and the optimal spacing between array elements are determined. The transducer's 300kHz horizontal and vertical beamwidths are greater than or equal to 46 degrees (-3dB fluctuation), such as Figure 4 and Figure 5 shown. The fluctuation of the voltage transmission response within the range of 265 ~ 330kHz is 6dB ( image 3 ), at 300kHz, 846.9w electric power is applied, the sound source level is 206.8dB, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com