New process for shortening fermenting period of salted tuber mustard

A new technology, mustard mustard technology, applied in the fields of application, food preparation, food science, etc., can solve the problems that the temperature cannot be controlled and can only be affected by weather and temperature, and achieve the effect of improving quality, reducing the inventory of mustard mustard, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

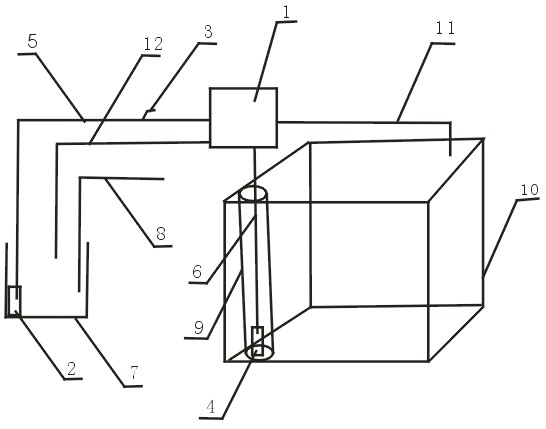

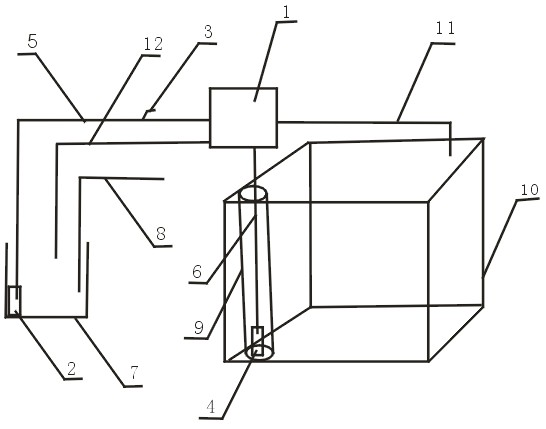

[0025] A new process for shortening the ripening cycle of salted pickled mustard, including a heat exchanger, a hot water pump, a control valve, a thermometer, a brine pump, a hot water pipe, a brine pipe, a hot water storage pool, a steam pipe, a bamboo basket, a salting pool, The brine pipe two and the return pipe, the brine pump is placed in the bamboo basket, and the bamboo basket is set in a corner of the salting pool, the brine pump is connected to the heat exchanger through the brine pipe one, and a thermometer is set at the connection, and the hot water pump is set in the hot water At the bottom of the storage tank, a steam pipe is inserted into the hot water storage tank. The hot water pump is connected to the heat exchanger through the hot water pipe. A control valve and a thermometer are respectively set at the connection. The upper end of the heat exchanger and the hot water storage tank is also connected with a return flow The heat exchanger is connected to the dia...

Embodiment 2

[0028] Around the end of January and the beginning of February around the Spring Festival, green vegetables are picked as salted mustard. The salting process is: harvesting of green vegetables → cleaning → first salting → circulating salt water → turning the pond → adding salt and showering cycle → cover salt → sealing sand. After sealing the sand, it enters the fermentation period, and warms the clean water: first, heat the clean water to 35-45°C with steam in the hot water storage tank, turn on the power supply of the hot water pump, and transport the hot water to the heat exchanger through the hot water pipe , the hot water exchanges heat with the lower temperature brine in the heat exchanger, and after the temperature is lowered, it is transported to the hot water storage tank through the return pipe for heating and recycling; It is sent to the heat exchanger through the brine pipe one, and the temperature rises after heat exchange with hot water in the heat exchanger, and...

Embodiment 3

[0030] Around the end of January and the beginning of February around the Spring Festival, radishes are picked as salted mustard. The salting process is: harvesting of green vegetables→cleaning→first salting→circulating salt water→turning the pool→salting and showering cycle→covering salt→sealing sand. After sealing the sand, it enters the fermentation period, and warms the clean water: first, heat the clean water to 35-45°C with steam in the hot water storage tank, turn on the power supply of the hot water pump, and transport the hot water to the heat exchanger through the hot water pipe , the hot water exchanges heat with the lower temperature brine in the heat exchanger, and after the temperature is lowered, it is transported to the hot water storage tank through the return pipe for heating and recycling; It is sent to the heat exchanger through the brine pipe one, and the temperature rises after heat exchange with hot water in the heat exchanger, and then it is sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com