Continuously working and controllable electrostatic jetting device

An electrostatic spraying and working technology, applied in spraying devices, spray discharge devices, etc., can solve the problems of difficulty in ensuring the stability of the spraying process, restricting rapid application development, and inability to apply, and achieve the effect of long-term stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

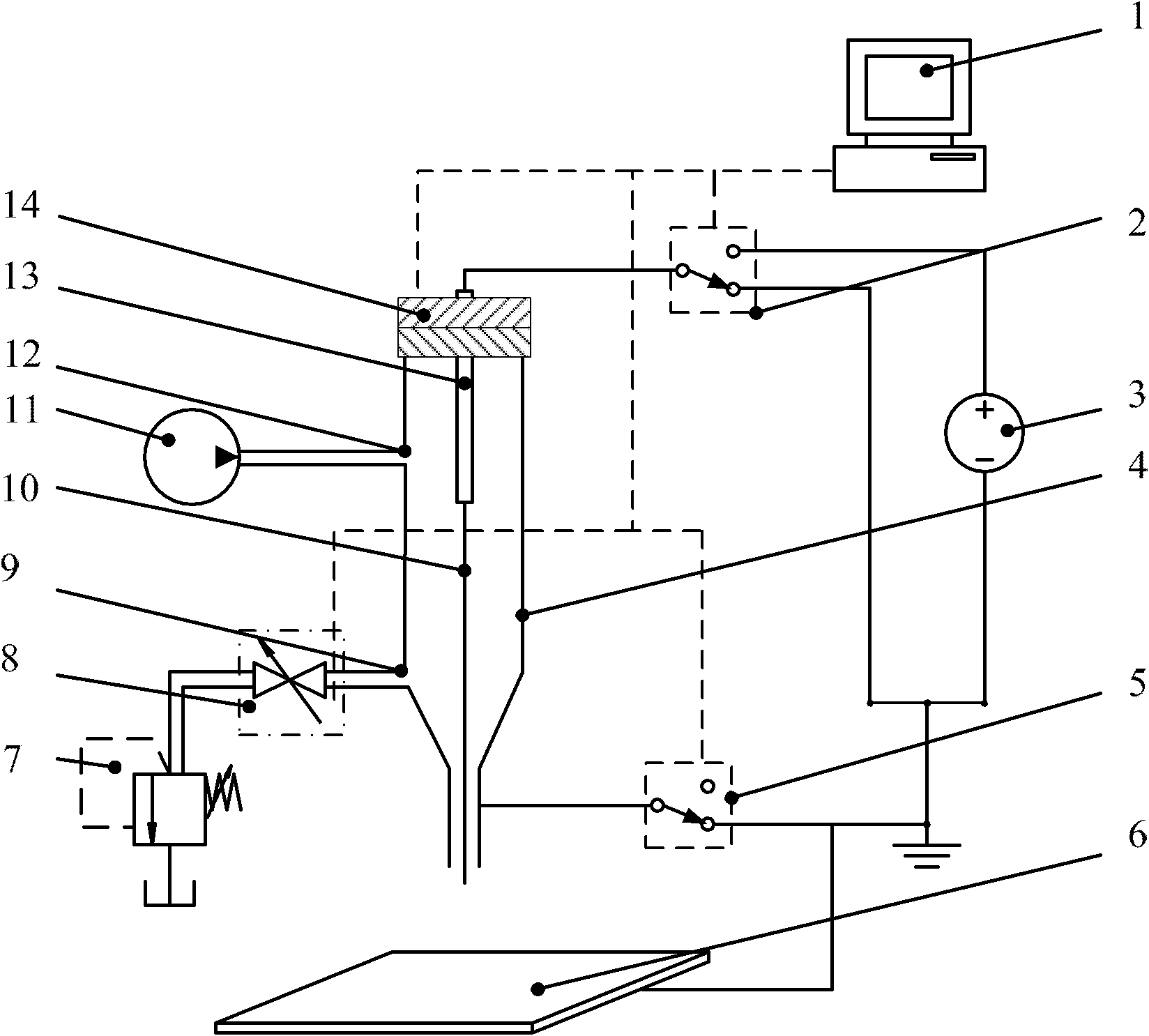

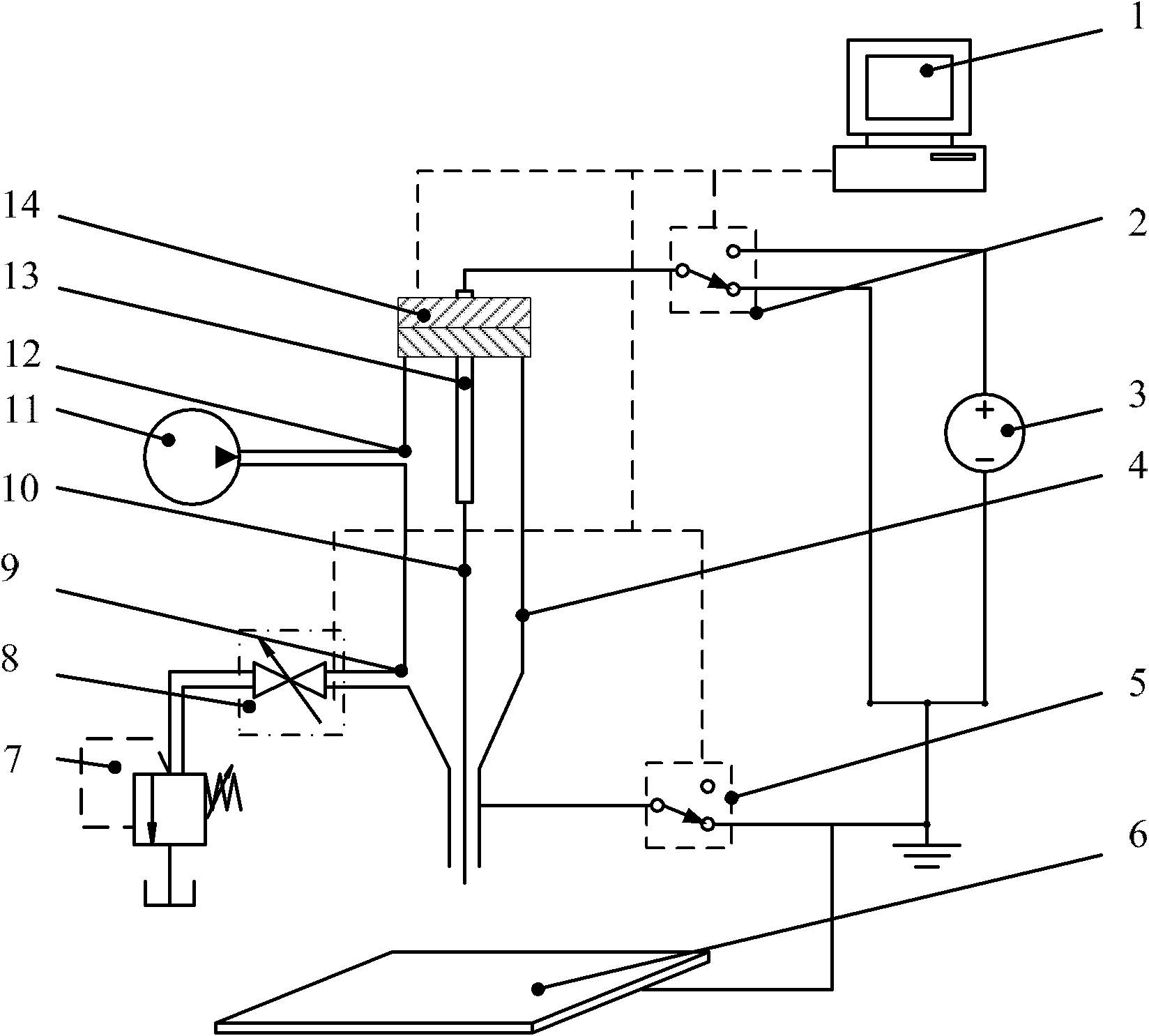

[0017] like figure 1 As shown, the embodiment of the present invention is provided with a hollow nozzle 4, a nozzle lower channel 9, a nozzle upper channel 12, a conductor probe 10, an insulating sealing sleeve 13, an electric screw regulator 14, a precision injection pump device 11, and a switching valve 8 ( With pressure regulating mechanism), negative pressure chamber 7, high voltage relay 2, electrostatic high voltage power supply 3, conductive relay 5, controller 1 and collecting plate 6.

[0018] The lower end of the hollow spray head 4 is provided with a nozzle, and the upper end of the hollow spray head 4 is provided with a cover. The insulating sealing sleeve 13 of the conductor probe 10 is arranged in the hollow shower head 4 , the conductor probe 10 is fixed in the insulating sealing sleeve 13 , and the lower end of the conductor probe 10 exposes the nozzle of the hollow shower head 4 . The insulating sealing sleeve 13 is fixed on the electric screw adjuster 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com