Method for separating domestic garbage

A technology for domestic waste and sorting, applied in the field of domestic waste recycling, can solve the problems of inability to adapt to the characteristics of domestic waste, unable to achieve separation effect, complex components, etc., to achieve compact sorting process, small footprint, optimized Effects of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

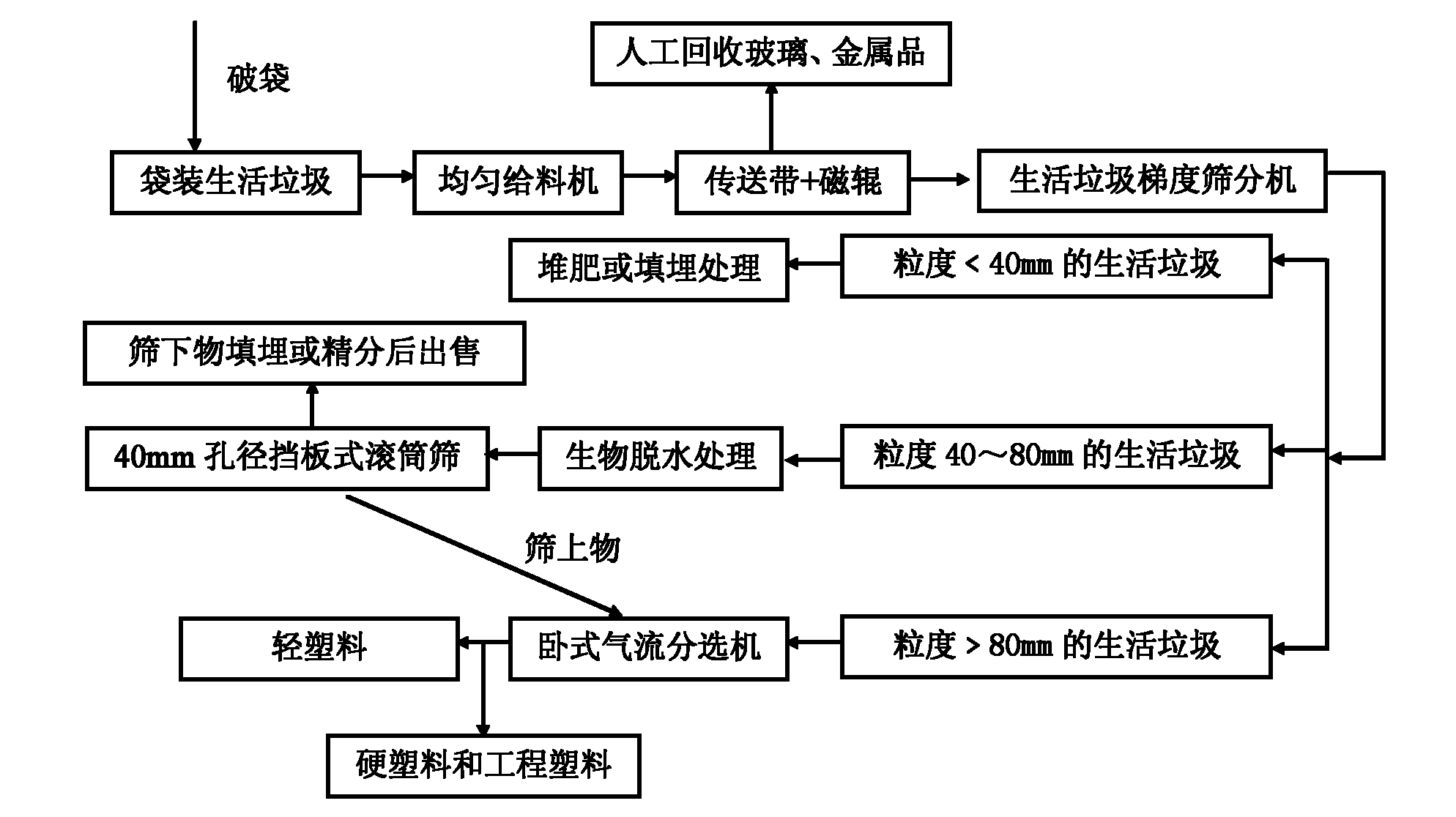

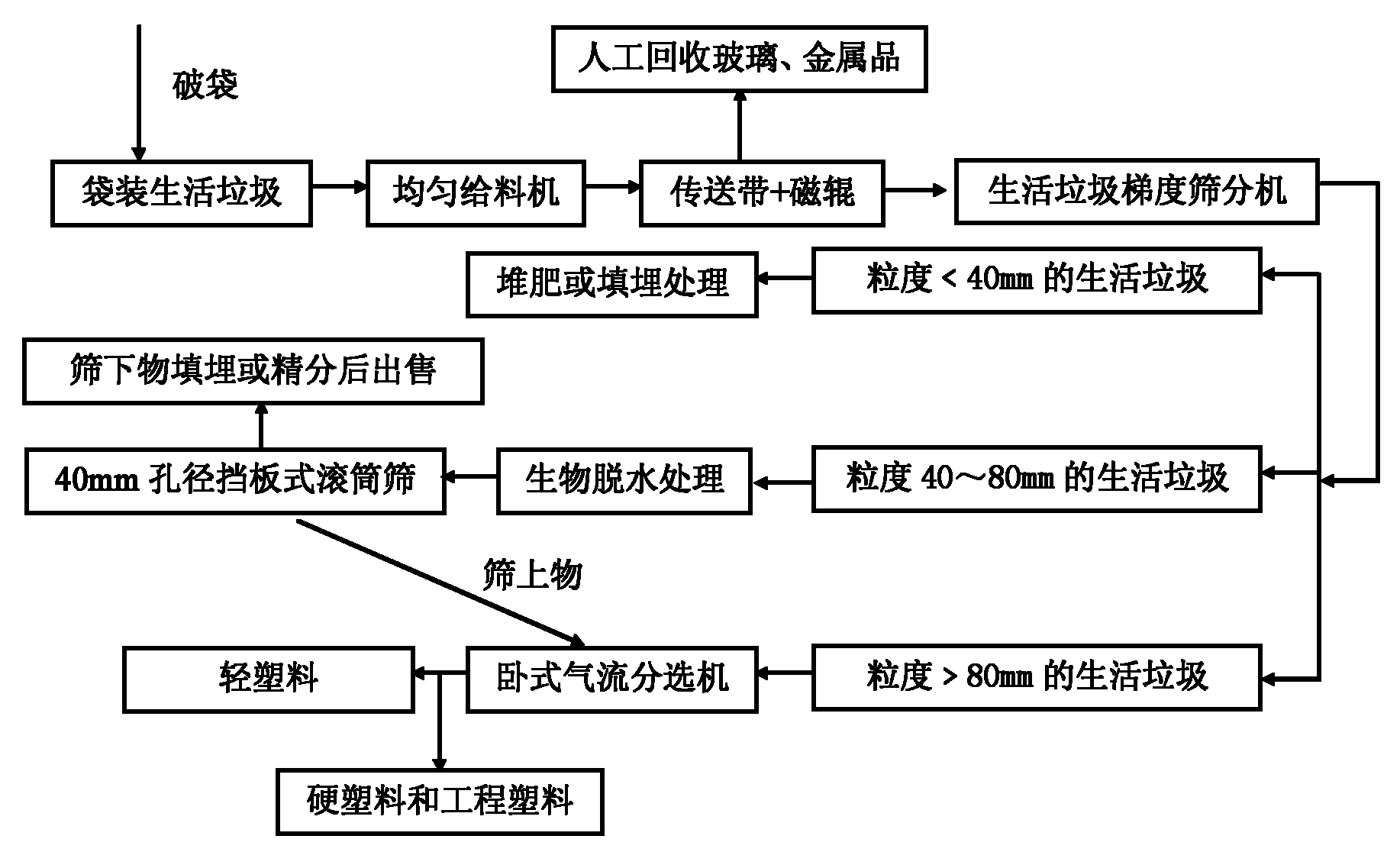

Method used

Image

Examples

Embodiment 1

[0029] Taking domestic waste from a landfill in Shanghai as an example, the components of domestic waste are shown in Table 1

[0030] Table 1 Analysis of waste components in a domestic waste landfill in Shanghai (wet basis, 100%)

[0031] Kitchen waste

ceramics and bricks

waste plastic

Glass

bamboo, wood

Muck and others

47.56

2.93

6.64

19.93

0.10

3.05

3.63

0.12

0.59

15.45

[0032] (1) Break 200kg of the household garbage first, then manually pick up 7.34kg of glass,

[0033] (2) A total of 0.22kg of metal is picked up by hand and magnetically separated by magnetic roller.

[0034] (3) The rest of domestic garbage enters the combined trommel screen, which operates under the conditions of v / V of 0.54 and angle of 6.0°.

[0035] (4) After being sieved by the drum of the above-mentioned integrated machine, the domestic garbage is distribu...

Embodiment 2

[0040] Taking domestic waste in a city in Jiangsu as an example, the components of domestic waste are shown in Table 2

[0041] Table 2 Domestic waste components in a city in Jiangsu (wet basis, 100%)

[0042] Kitchen waste

plastic

paper

the fabric

Bamboo

Glass

Brick ceramics

Muck and others

43.86

3.83

4.81

3.79

1.53

0.47

1.28

5.07

35.36

[0043] (1) Take 200kg of the domestic waste for sorting, first break the bag, pick up 3.47kg of glass by hand,

[0044] (2) A total of 0.92kg of metal is picked up by hand and magnetically separated by magnetic roller.

[0045] (3) The remaining domestic garbage enters the combined trommel screen, which operates under the conditions of v / V of 0.45 and angle of 5.3°.

[0046] (4) After being sieved by the drum of the above-mentioned integrated machine, the domestic garbage is distributed to the outlet of 80mm;

[0047](5) After being sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com