On-line measuring method and device of camber of steel plate

A measuring method and technology of measuring device, which are applied in the direction of length measuring device, mechanical counter/curvature measurement, metal rolling, etc., can solve the problems of production rhythm conflict, affecting the rhythm of steel plate off-line, measurement difficulty, etc., to solve the production rhythm conflict, quickly measure camber, reduce direct-acting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

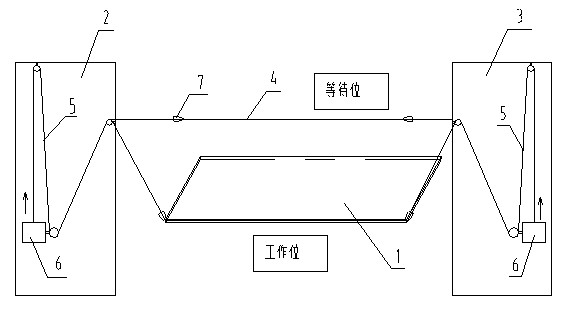

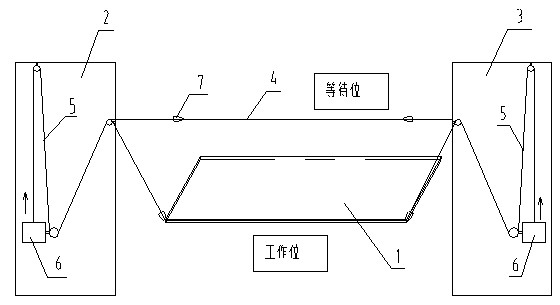

[0021] This embodiment provides a method and device for online measurement of camber of steel plate, the structure of the device is as follows figure 1 As shown, it includes pulley blocks 2 and 3 located on both sides of the steel plate 1, and the two pulley blocks are connected by a wire caliper 4 above the steel plate 1, and the other end of the wire caliper 4 is hung by a wire rope 5 wound on the pulley block. Lead weight 6 at the other end of the pulley block. The pulley block is made up of 3 pulleys, which are respectively located at the top, the middle and the bottom from top to bottom, the lead weight 4 is located at one end of the upper pulley, and the steel wire caliper 4 is connected with one end of the middle pulley. The two ends of the steel wire caliper 4 are respectively provided with a movable clamping block 7 .

[0022] The on-line measurement method of steel plate sickle bend is carried out according to the following steps:

[0023] ⑴A pulley block is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com