Dadoing device for metal plate bending machine

A bending machine, metal plate technology, applied in the direction of planer, metal processing equipment, planer/slotting machine, etc., can solve the problems of difficult to process small edges of patterns, unreasonable structure and control, and reduced processing accuracy, etc. Simple structure, improve precision and quality, reduce the effect of bending chamfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

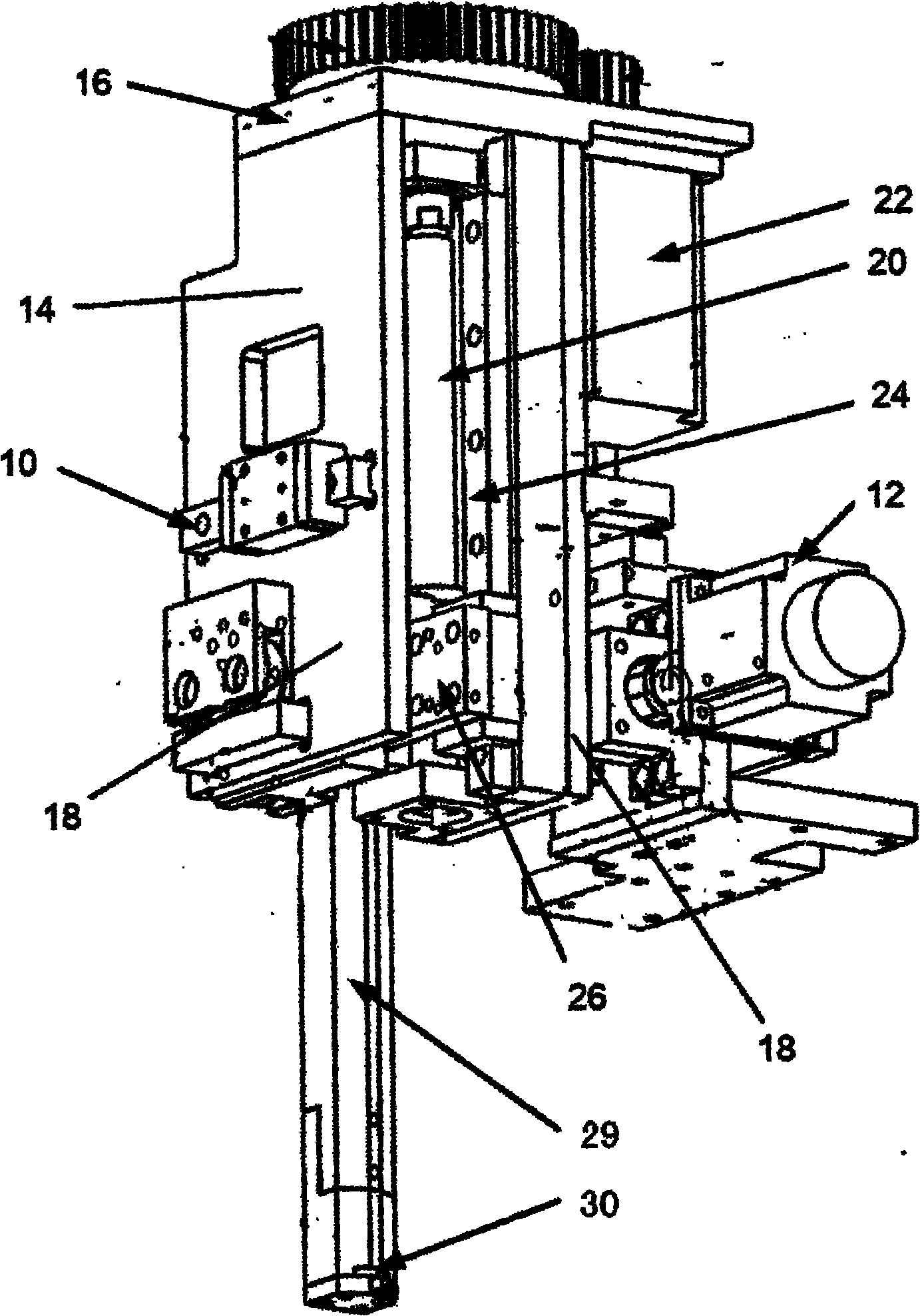

[0017] like figure 1 , figure 2 and image 3 As shown, a grooving device for a sheet metal bending machine of the present invention includes a horizontal slide rail 10 and a first stepping motor 12 arranged on an operation table (not shown) of the sheet metal bending machine. A planer seat 14 is arranged on the horizontal slide rail 10 , and the first stepping motor 12 can drive the planer seat 14 to move along the horizontal slide rail 10 .

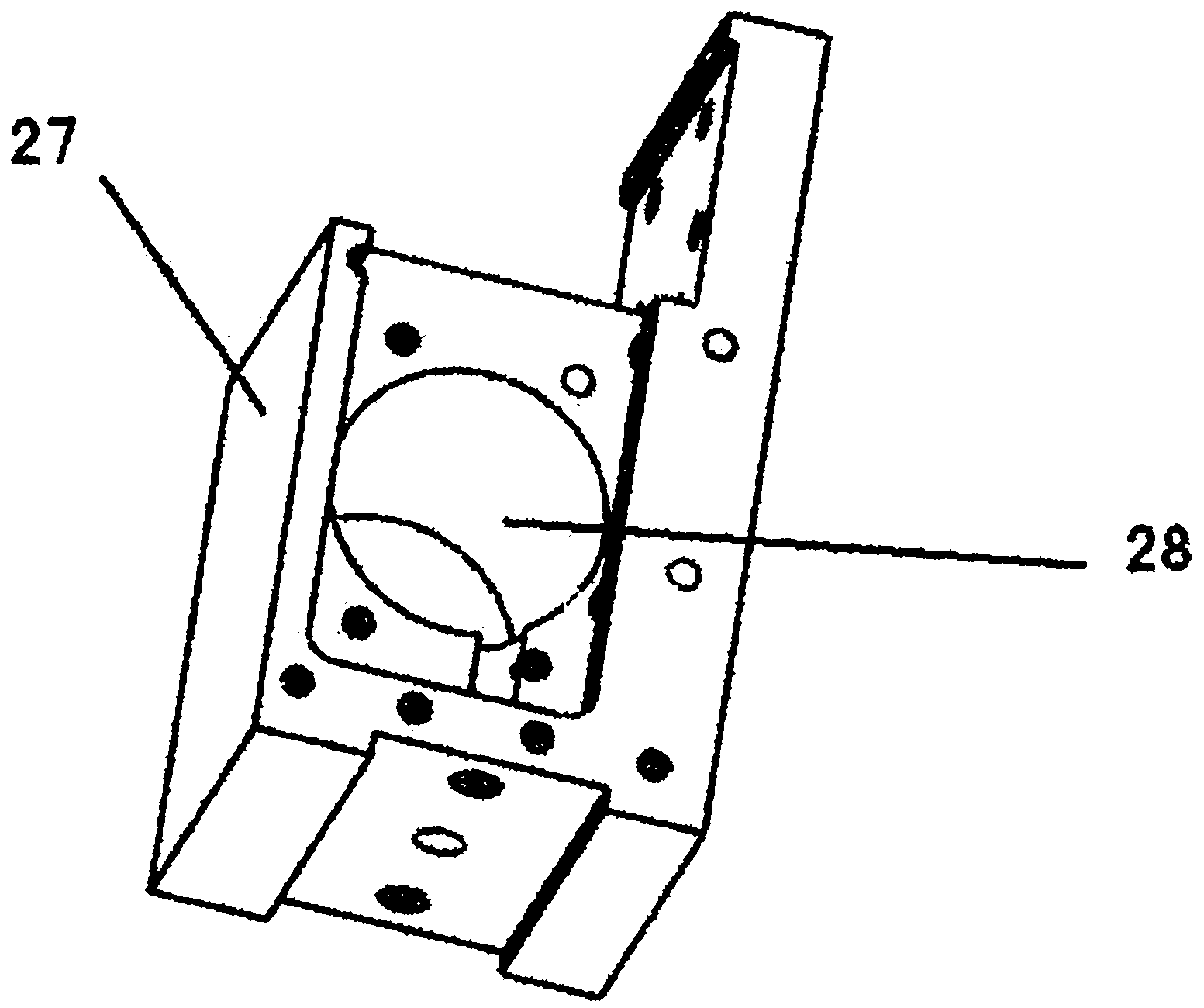

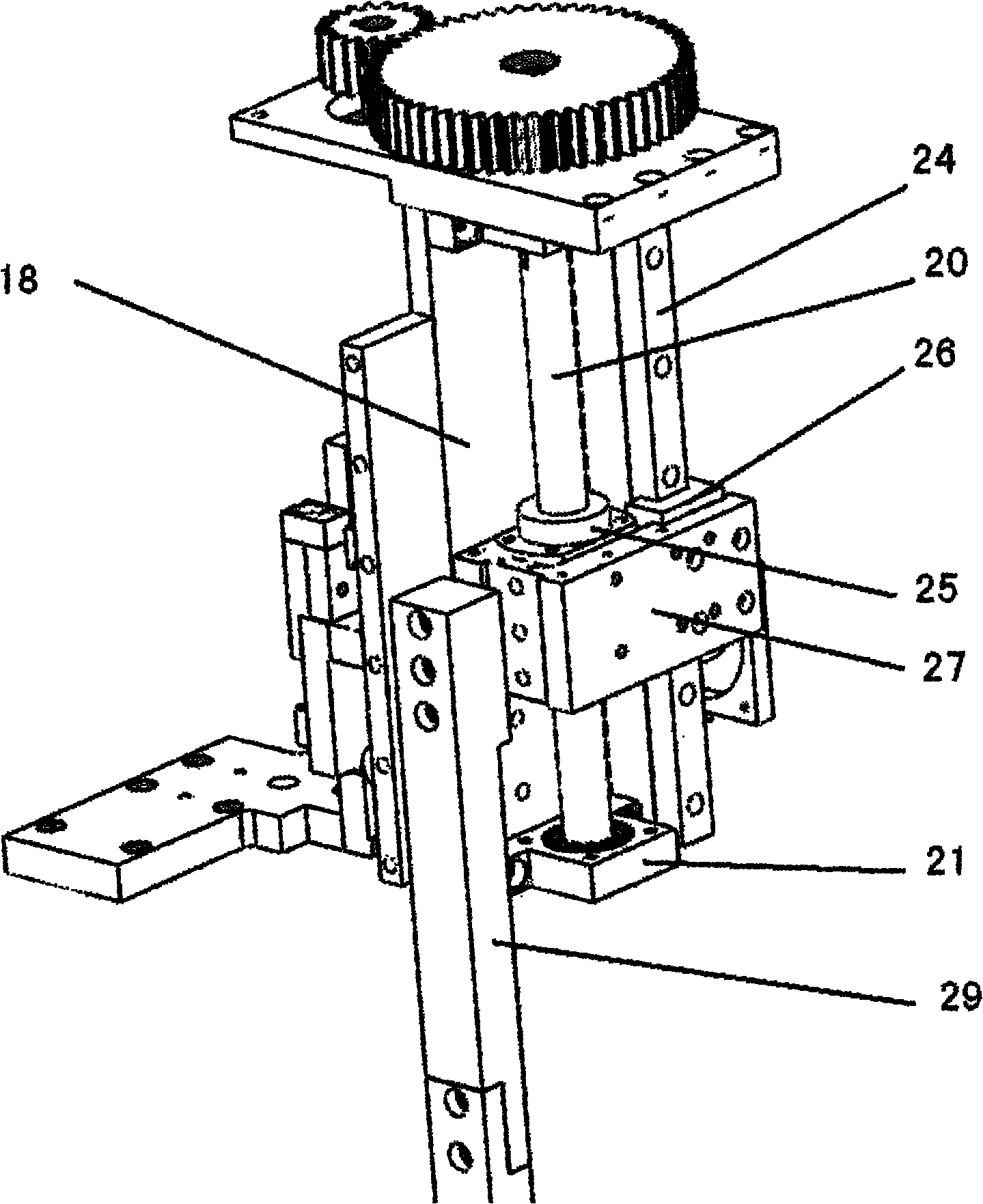

[0018] The planer holder 14 is a mouth-shaped structure, which includes a horizontal top plate 16 and a bottom plate (not shown) and vertical side plates 18 between the top plate 16 and the bottom plate. A threaded mandrel 20 is passed between the top plate 16 and the bottom plate, and the threaded mandrel 20 is fixedly connected to the side 18 through a bearing 21 . A second stepping motor 22 is provided on the side of the screw shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com