Insert mold transcription film including three-dimentional pattern of metal texture and method for fabricating the same

A manufacturing method and film technology, applied in the direction of copying/marking method, imitating three-dimensional effect patterns, metal layered products, etc., can solve the problems of unnatural patterns and reduced processing elongation rate, so as to omit follow-up engineering and high elongation rate , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

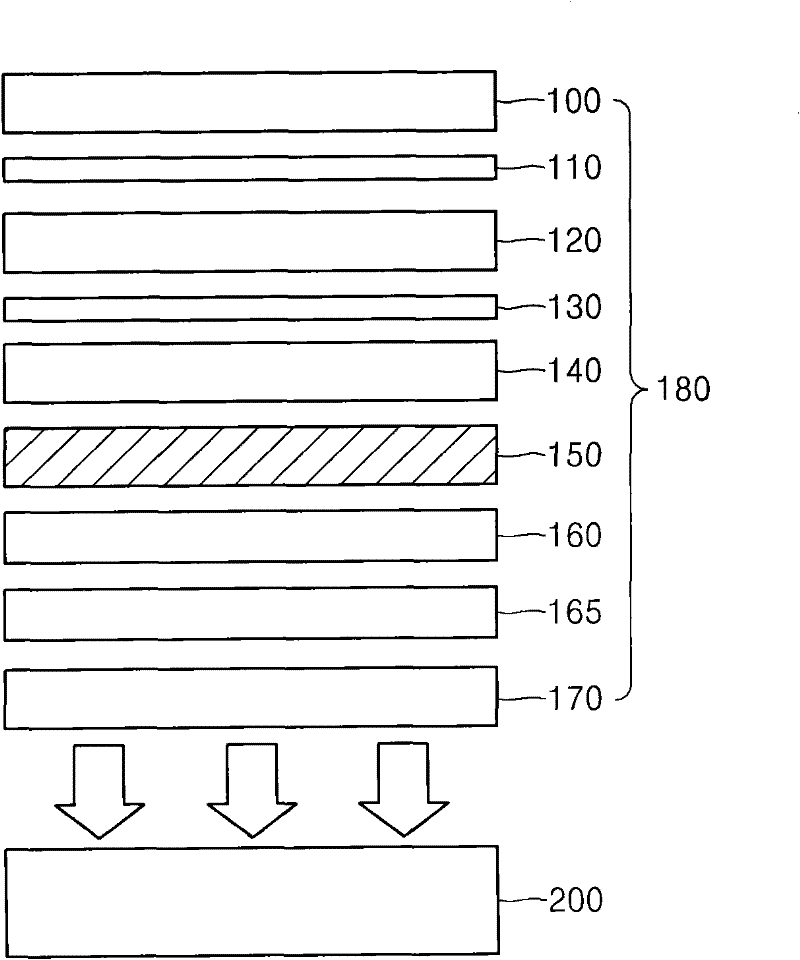

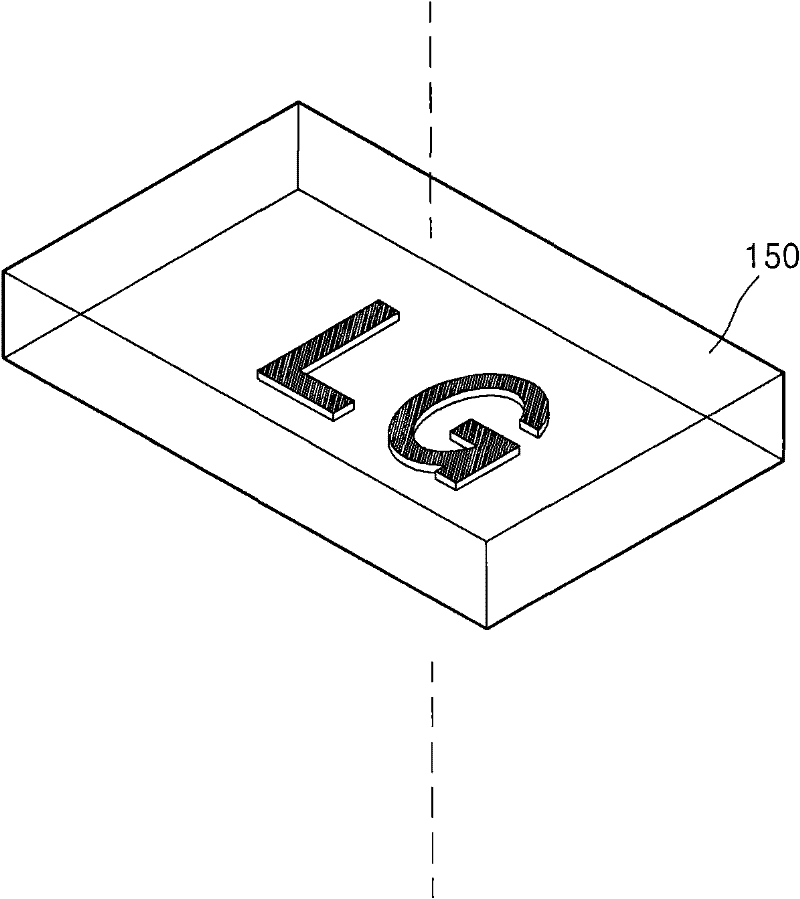

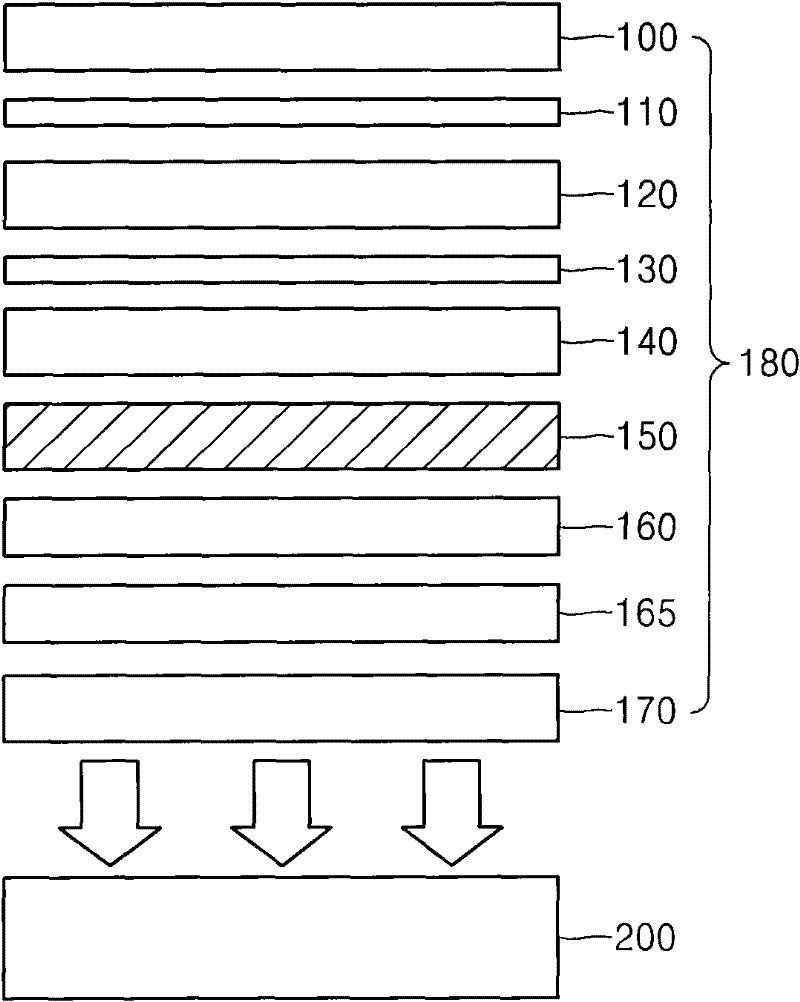

[0022] The invention provides an interspersed mold transfer printing film including a metallic three-dimensional pattern and a manufacturing method thereof, which has excellent printability, adhesion, and solvent resistance, and embodies a three-dimensional three-dimensional pattern with a distinct metallic texture and high hardness.

[0023] Hereinafter, the through-mold transfer film including the metal texture three-dimensional pattern and the manufacturing method of the present invention will be described in detail.

[0024] The advantages, features and implementation methods of the present invention are clearly described with preferred embodiments and methods with reference to the accompanying drawings. However, the present invention is not limited to the embodiments, but various forms can be realized in different ways. The following embodiments are provided so that those skilled in the art can successfully implement the present invention, and the present invention is def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com