Biomass polyester

A biomass and polyester technology, applied in the field of biomass polyester, can solve the problems of difficult control of cross-linked products and long reaction time, and achieve the effects of easy control of cross-linking degree, short reaction time and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of polyxylitol malate (PXM): Mix DL-malic acid and xylitol according to [-COOH]:[-OH] = 1:1, add 10ml ethanol, add 0.1 ~ 0.6ml 20% sulfuric acid, heated to dissolve completely. Cool, pour on a metal surface, then place in an oven at 100 o C~120 o C heating 10h, a colorless film is obtained, the glass transition temperature T g = -19 o c.

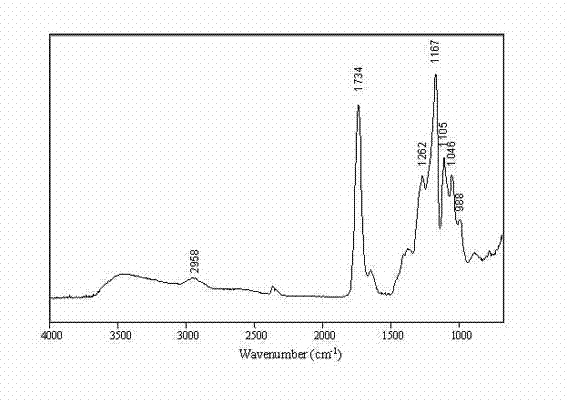

[0045] The product prepared above was detected by infrared spectroscopy to obtain the attached figure 1 , in the figure, the characteristic peak related to the ester group appears at 1734 cm -1 (ester group C=O expansion) and 1167cm -1 (Ester group C-O-C stretching) and other positions.

Embodiment 2

[0047] Similar to Example 1, but the reactant malic acid and xylitol ingredient ratio is changed to [-COOH]:[-OH] = 1:2 mixing, the other remains unchanged, after heating for 10h, a colorless film is obtained, and the glass transition temperature T g = -5 o c.

Embodiment 3

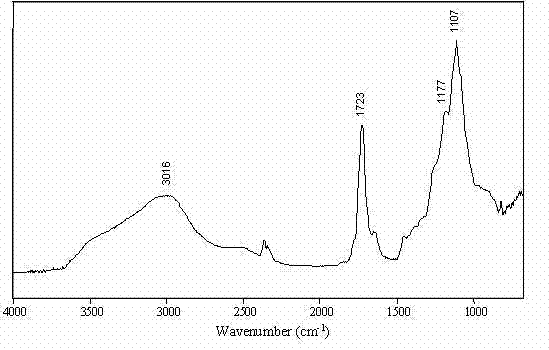

[0049] Preparation of polyglyceryl itaconate (PGI): mix 1.3010 g of itaconic acid with 0.73 ml of glycerin, add 20 ml of ethanol, add 0.5 ml of 20% sulfuric acid, and heat to dissolve completely. Cool, pour onto a metal surface, then place in a vacuum oven at 90 o C or 100 o C heating 11h, a colorless or light yellow film. The product was detected by infrared spectroscopy figure 2 , in the figure, the characteristic peak related to the ester group appears at 1723 cm -1 (ester group C=O expansion) and 1107cm -1 (Ester group C-O-C stretching) and other positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com