Preparation of biodegradable fermentation organic acid ployester

A biodegradation and organic acid technology, applied in the field of polymer materials, can solve the problems of limited sources of raw materials and catalysts, difficult control of cross-linked products, long reaction time for synthesis and preparation, etc. and social benefits, the effect of easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

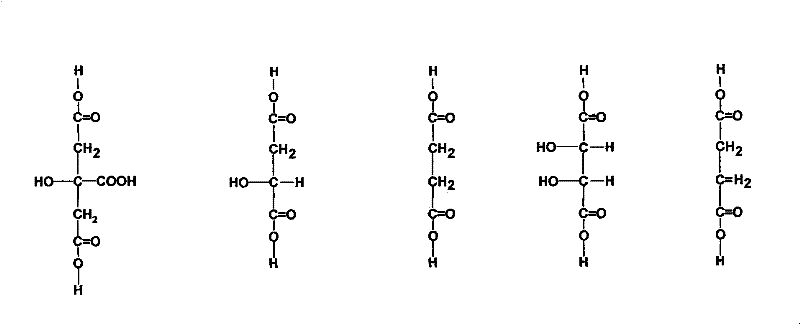

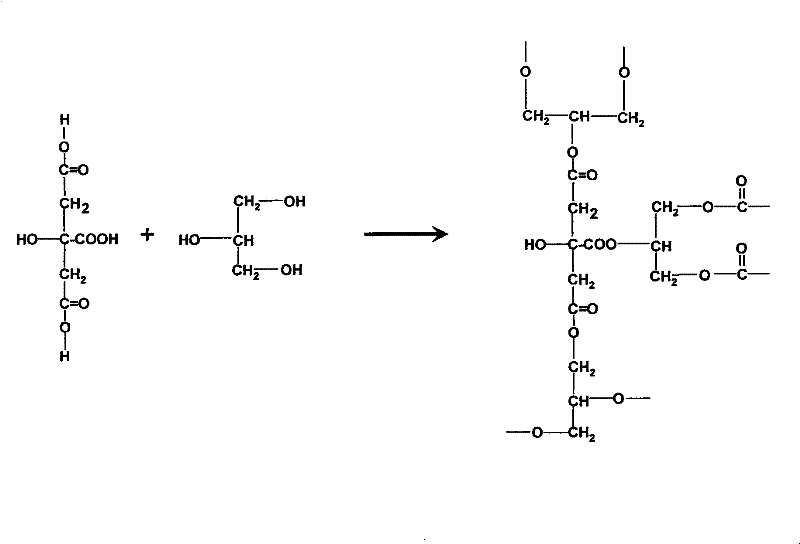

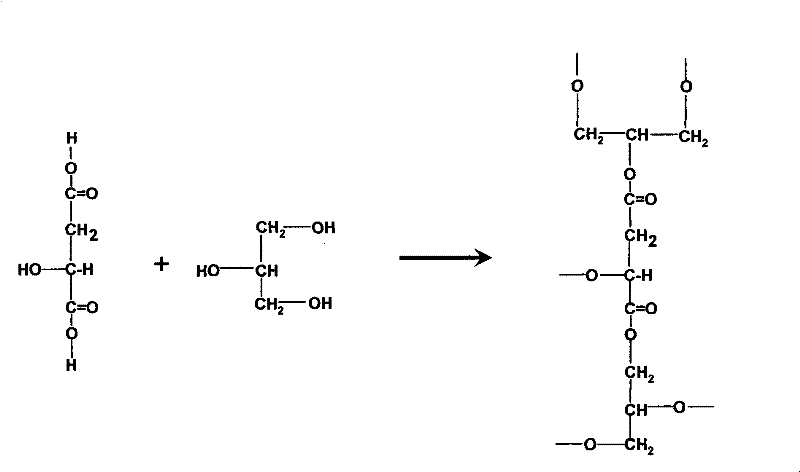

Method used

Image

Examples

Embodiment 1

[0034] Add weighed 28.78g citric acid, 10.0ml glycerin and 2 drops of 25% sulfuric acid solution in the flask of rotary evaporator. Turn on the vacuum pump, and when the vacuum degree reaches about -0.09MPa, turn on the heating and rotary switch of the rotary evaporator to allow it to react. The temperature of the oil bath is controlled at 50-90°C, and the mixture is evenly mixed. After about 30 minutes, a prepolymer is initially formed. The prepolymer is coated on 16 glass slides respectively, placed in a blast drying oven, and reacted for 14 hours to 36 hours respectively, and the temperature is controlled at 60-160°C. After the reaction is completed, take it out, put it in an enamel square plate and soak it in distilled water 12-24 hours, until the product falls off from the glass slide, dry at 110°C or dry the product at 70°C under vacuum. The product prepared above was detected by infrared spectroscopy to obtain the attached Figure 5 , in the figure, the characteristic...

Embodiment 2

[0039] Add weighed 14.80g citric acid, 5.0ml glycerin and 2 drops of 25% sulfuric acid solution in the three-necked flask, add water 10mL. Reflux at 80°C for 1 hour and mix well. Cast the solution on the surface of a clean glass or polytetrafluoroethylene plate, place it in a blast drying oven, control the temperature at 110-150°C and react for 12-36 hours, take it out after the reaction is completed, and place it in an enamel square plate for use Soak in distilled water for 12 to 24 hours until the product falls off the glass or Teflon surface, and vacuum dry the product at 70°C.

Embodiment 3

[0041] Add 5.0ml glycerin, 14.80g citric acid, and 2 drops of 20% sulfuric acid to the flask of the rotary evaporator, mix well, connect the rotary evaporator, the vacuum degree reaches about -0.09MPa, the temperature rises to 140°C, and rotate After 4 hours, it was poured out while it was hot, and the product solidified quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com