Wear-resisting blast-furnace tuyere small jacket

A technology of small tuyeres and blast furnaces, applied in the direction of tuyeres, etc., which can solve the problems of poor thermal conductivity, low service life, and peeling of the surfacing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

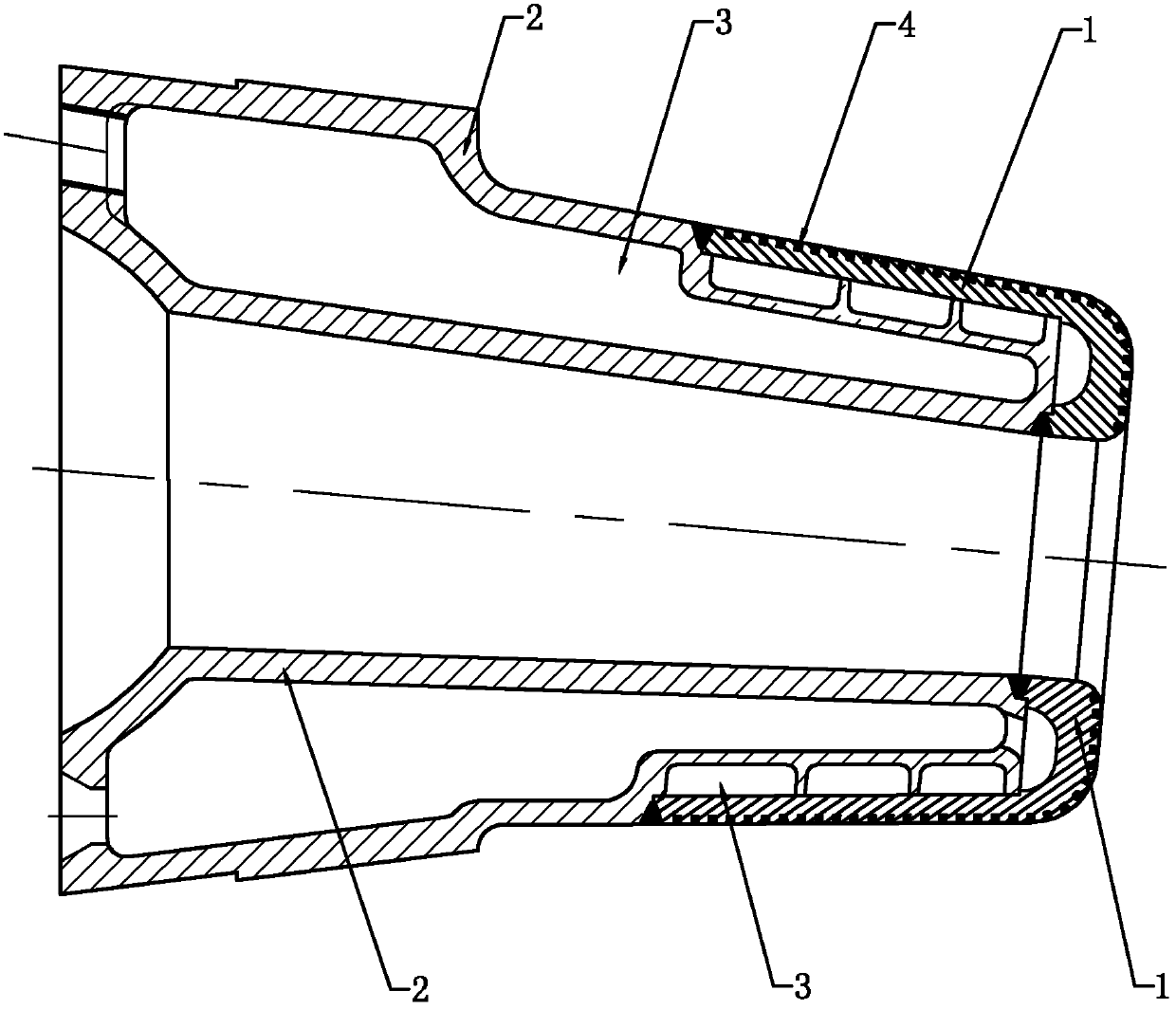

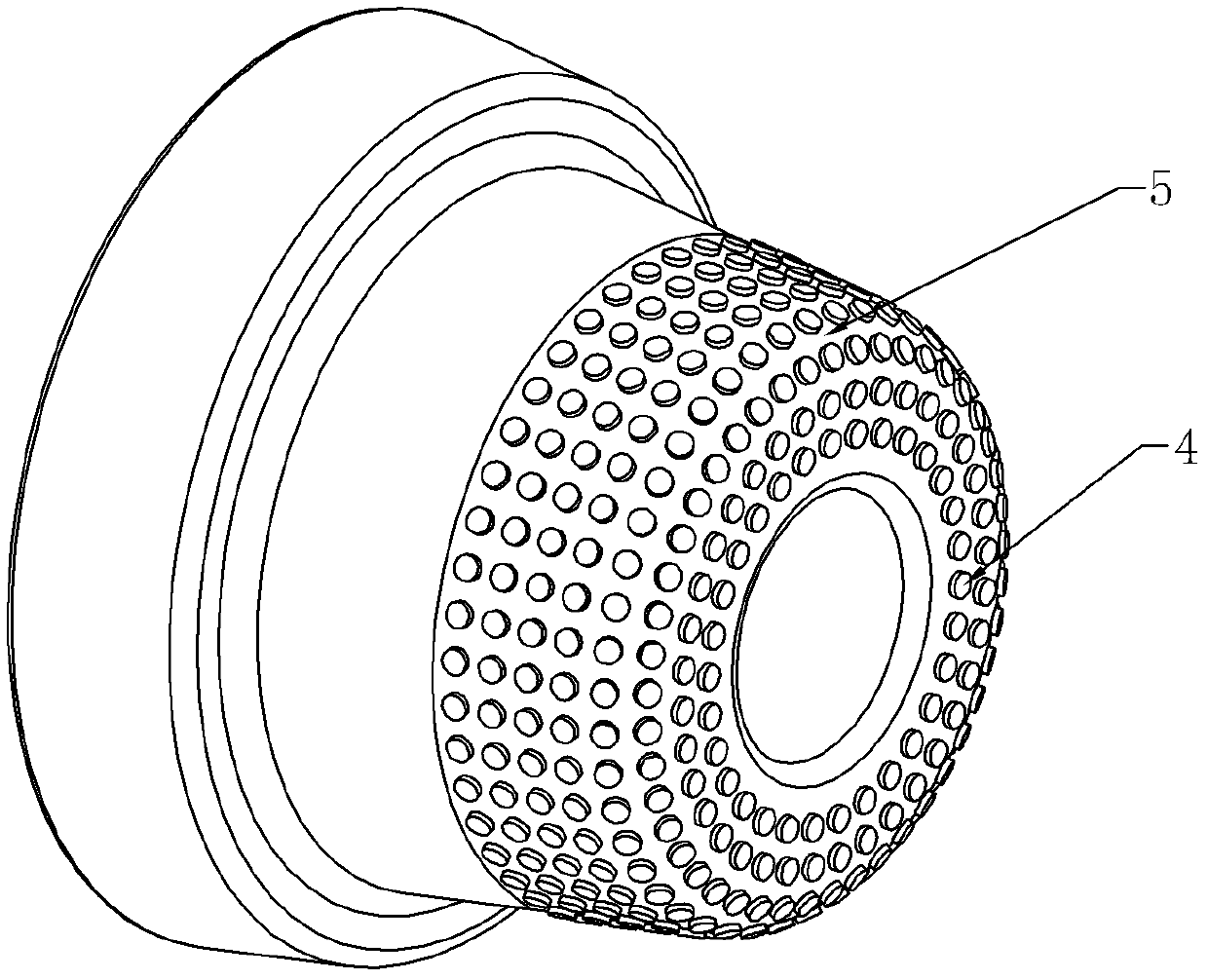

[0021] Example 1, such as figure 1 , figure 2 As shown, a wear-resistant blast furnace tuyere cover of the present invention includes a tuyere cap 1, a tuyere seat 2 and a water channel 3, wherein the tuyere cap 1 and the tuyere seat 2 are made of copper, and the front end and the outer wall of the tuyere cap 1 are embedded or cast Mechanically inlaid with a number of foam-shaped cylindrical inlays 4, the depth of the inlays 4 embedded in the copper matrix is 4 mm, the gap 5 between the inlays 4 is 10 mm, and the gaps are filled by the copper matrix. The diameter of the inlays 4 is 6 mm, inlay 4 is made of carbide. The inlay 4 can also be made of zirconium corundum, silicon carbide, ceramic, mullite or aluminum corundum.

Embodiment 2

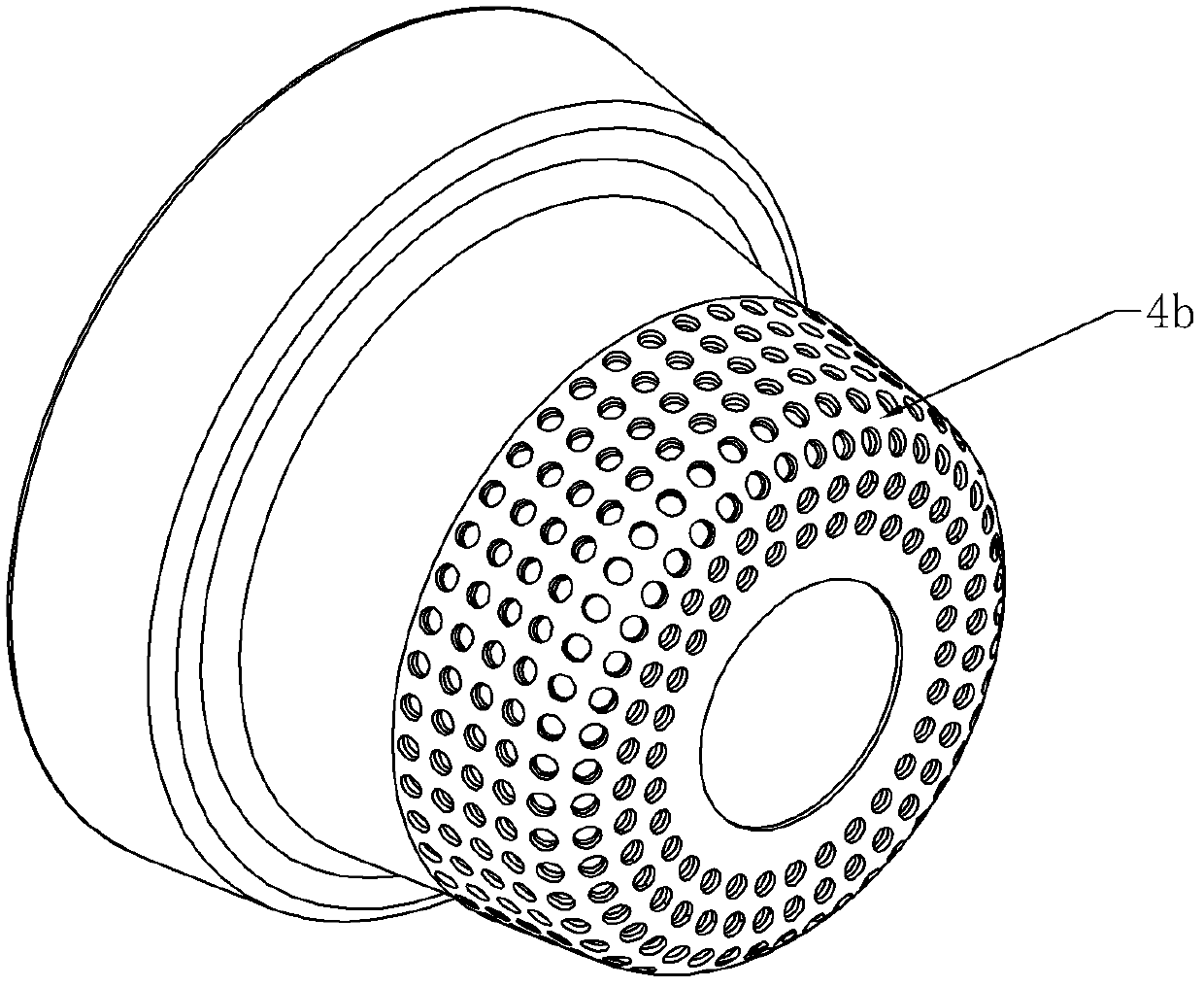

[0022] Example 2, such as image 3 As shown, the front end and the outer wall of the tuyere cap of a wear-resistant blast furnace tuyere cover are inlaid or mechanically inlaid with an inlay 4b. The depth of the inlay 4b embedded in the copper matrix is 2 mm, and several inlays 4b are processed. A circular hole, wherein the circular hole is a through hole, their diameter is 10 mm, the gap between the circular holes is 6 mm, the circular hole is filled with a copper matrix, and the inlay 4b is made of hard alloy. The inlay 4b can also be made of zirconium corundum, silicon carbide, ceramic, mullite or aluminum corundum.

Embodiment 3

[0023] Example 3, such as Figure 4 As shown, the front end and outer wall of the tuyere cap of a wear-resistant blast furnace tuyere cover are inlaid or mechanically inlaid with several annular inlays 4c. The width of the object 4c is 6 mm, the gap 6 between the annular inlays 4c is 10 mm, wherein the gap is filled with a copper matrix, and the inlay 4c is made of hard metal. The inlay 4c can also be made of zirconium corundum, silicon carbide, ceramic, mullite or aluminum corundum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com