Boundary layer turbine with blade plate

A kind of boundary layer and turbine technology, which is applied in the directions of blade support elements, stators, engine elements, etc., and can solve problems such as crushing, small flow channel clearance, and aggravation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

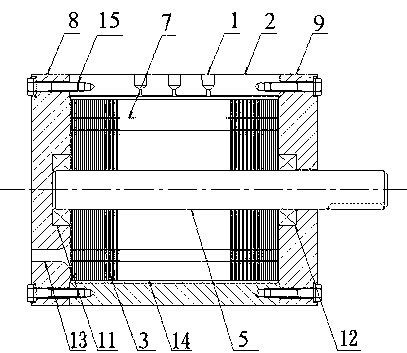

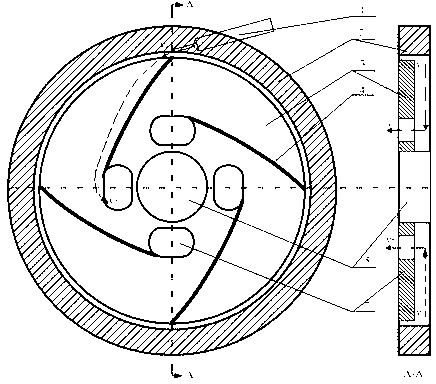

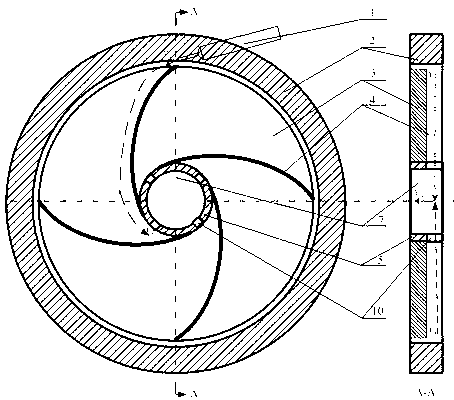

[0016] Referring to the accompanying drawings, the present invention provides a blisk-type boundary layer turbine, which includes a cylinder body 2, end covers 8 and 9 installed at both ends of the cylinder body 2, and also includes bearings 11 and 12 passing through the end cover and The rotating shaft 5 supported in the center of the cylinder, the rotating shaft 5 is installed with the working disc group 14, the blade 4 is installed between the adjacent working discs 3 in the working disc group 14, and the airflow direction at the inlet of the nozzle 1 is the same as that at the inlet of the blade 4. The included angle of the blade shape is 0 degree; the above-mentioned turbine working disk set 14 is provided with an outlet airflow passage 7, and the left end cover 8 is provided with a turbine airflow outlet hole 13.

[0017] Refer below figure 2 , image 3 The operation process of the bladed disk boundary layer turbine provided by the present invention will be described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com