Side incident LED (Light Emitting Diode) light source backlight module

A backlight module and side-entry technology, which is applied in the field of side-entry LED light source backlight modules, can solve problems such as light leakage and light loss, and achieve the effects of improving energy efficiency, brightness uniformity, and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a side-entry LED backlight module structure. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

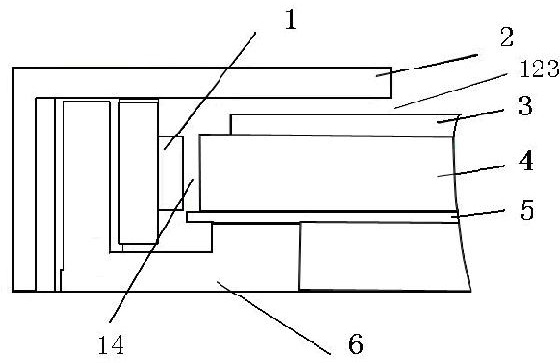

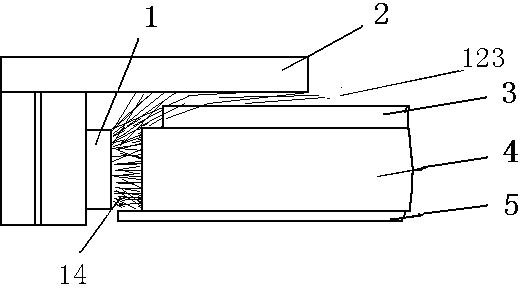

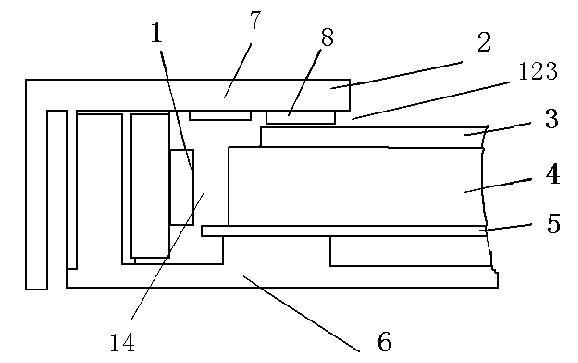

[0024] Such as Figure 3-4 As shown, Embodiment 1 of the present invention includes at least one LED light bar light source 1; middle frame bracket 2; optical sheet 3; light guide plate 4; reflection sheet 5; ; Absorbance buffer strip 8. It is characterized in that a specular reflective strip 7 is attached to the position corresponding to the middle frame bracket 2 in the gap 14 between the surface of the LED lamp and the light incident surface of the light guide plate, and a light-absorbing buffer is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com