Rock core sampling method

A technology for core and sample selection, which is applied in the direction of solid analysis and sorting using sound waves/ultrasonic waves/infrasonic waves, and can solve the problems of core pore structure, mechanical properties that cannot be evaluated, experimental results that lack comparison, and quantitative analysis that cannot be done. Achieve the effect of simple structure, strong practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment further illustrate the present invention.

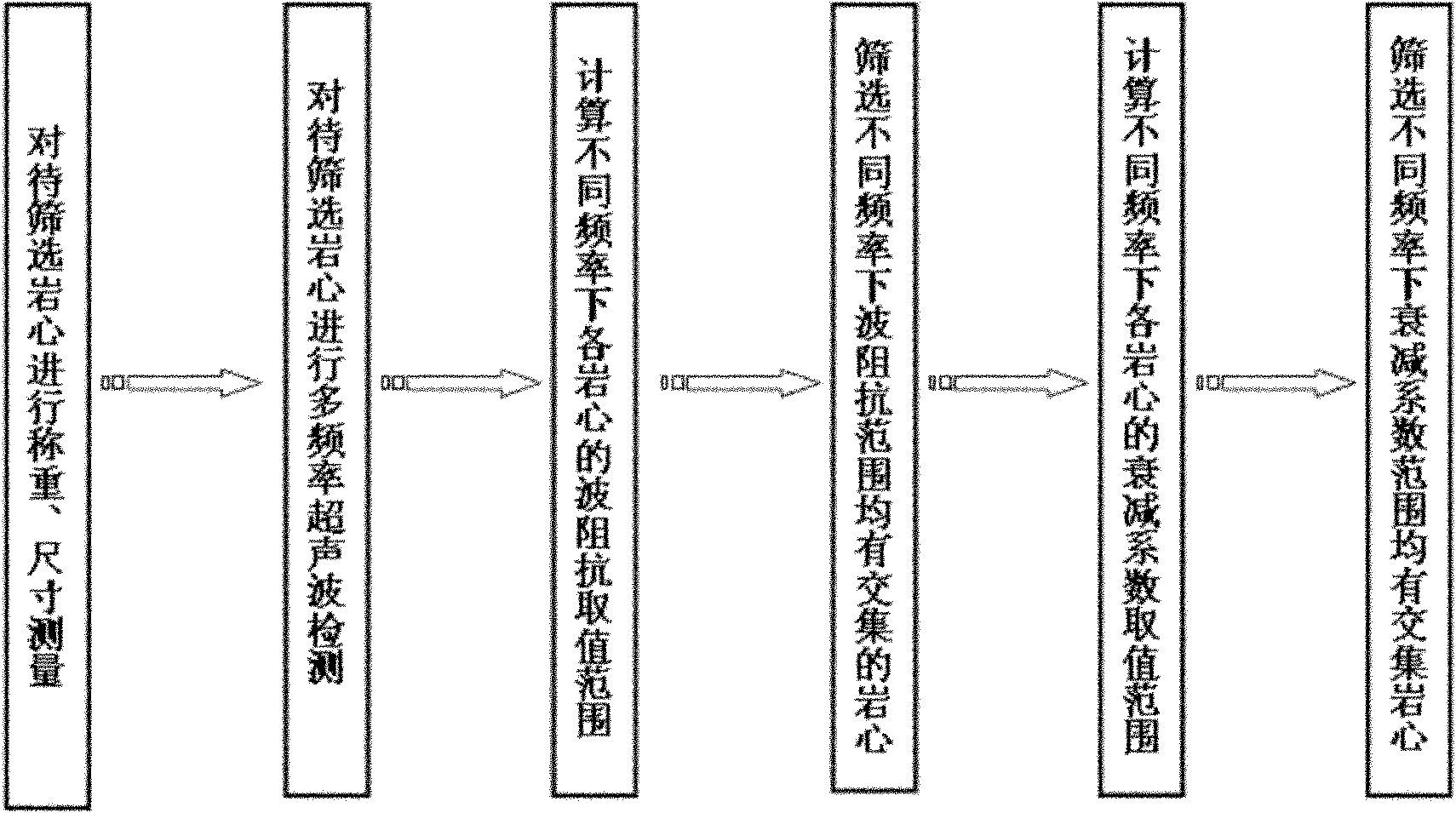

[0043] see figure 1 .

[0044]A method for core sample selection, the method comprises the following steps in sequence:

[0045] (1) Select 5 rock cores from the same strata section and block, measure the length and diameter with a vernier caliper with an accuracy of Δl=0.02mm, weigh with an electronic balance with an accuracy of Δm=0.0001g, and use time and amplitude with an accuracy of Δt =0.4μs, Δa=0.0039 digital oscilloscope to read the value, the data results are shown in Table 2;

[0046] (2) The rock core processed in (1) is subjected to ultrasonic testing using a multi-probe and different-frequency ultrasonic testing system, and the transmitting and receiving probes are respectively placed on both ends of the rock core, and appropriate confining pressure is added to allow the probe to fully contact the end face of the rock core. For better coupling, apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com