Bonding device, ultrasonic transducer, and bonding method

A bonding device and ultrasonic technology, applied in welding equipment, electric solid-state devices, semiconductor devices, etc., can solve the problems of hindering the rotation of the bonding head, too large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

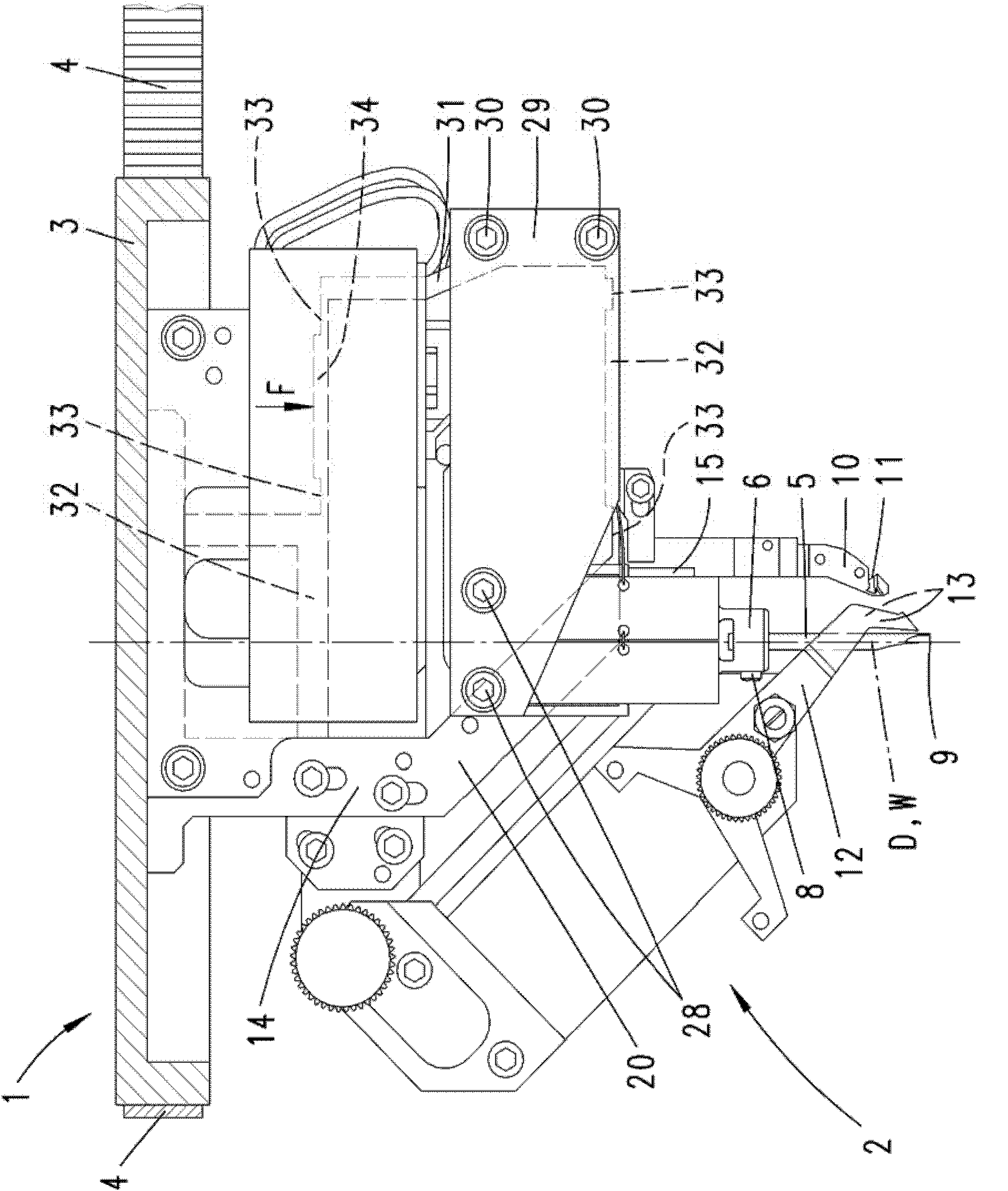

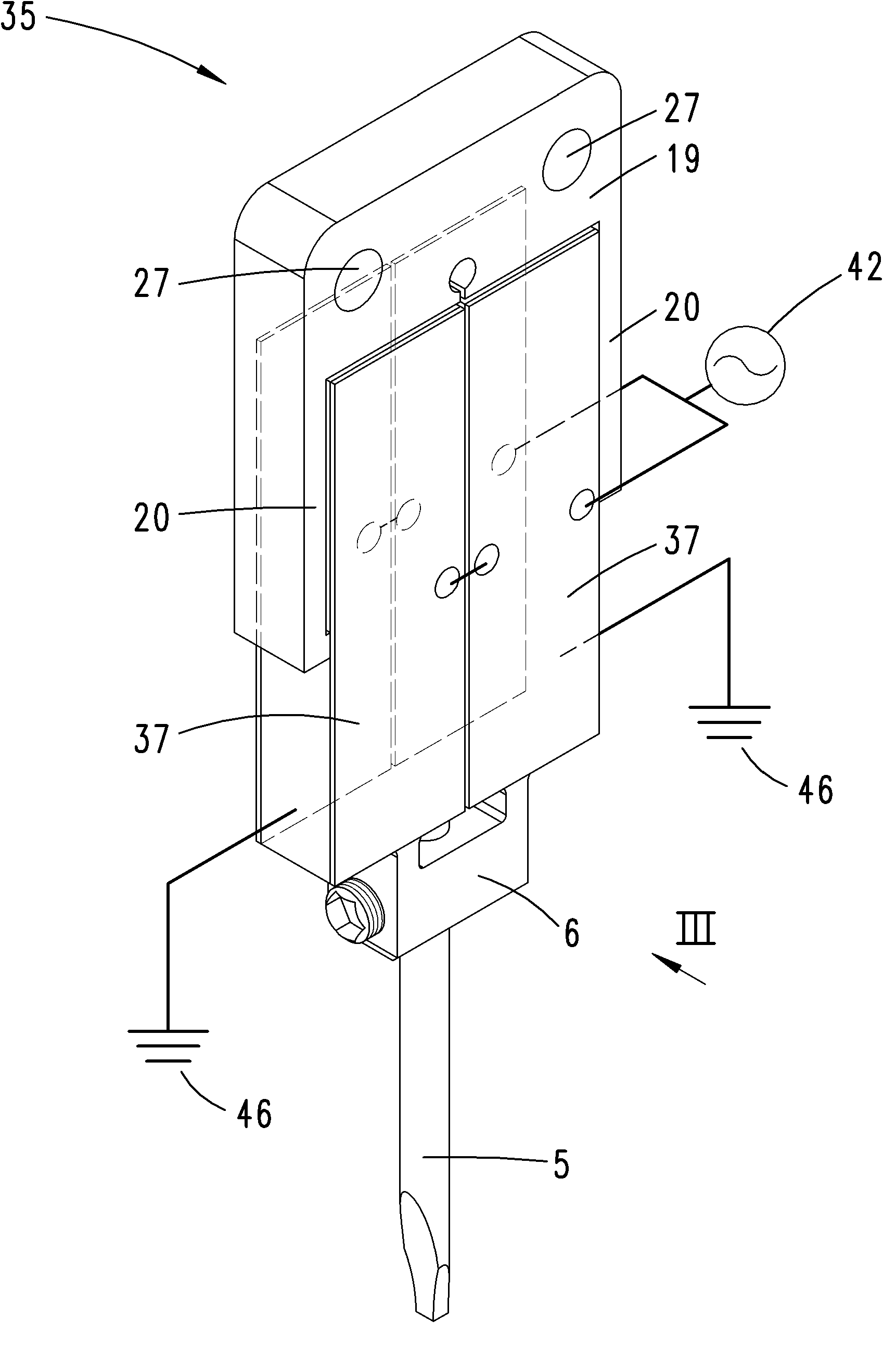

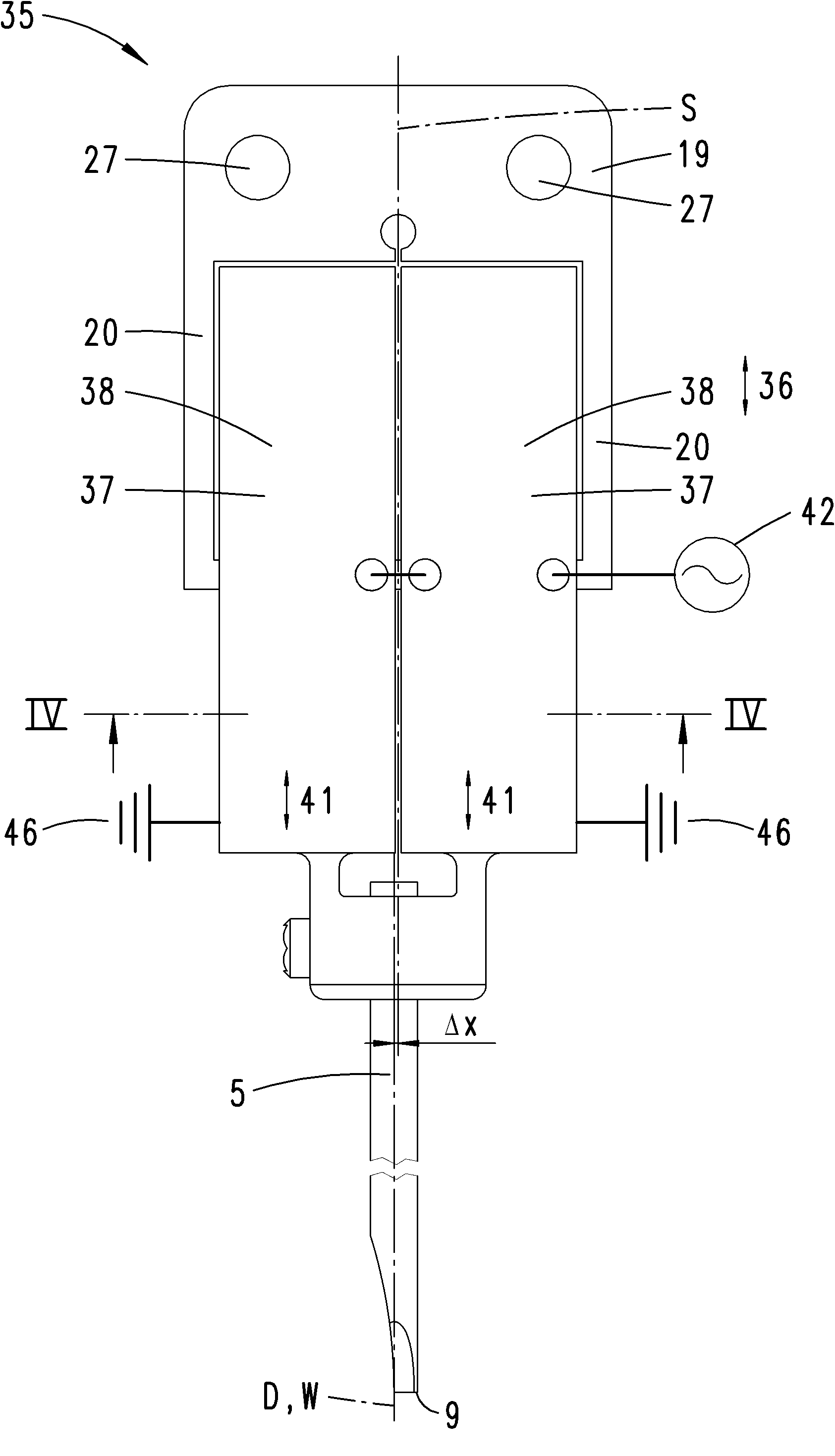

[0042] first reference Figures 1 to 6 A preferred embodiment of the splice device according to the invention and the method according to the invention for establishing a splice connection is described, figure 1 only shows bonding device 1 in the area of bonding head 2, Figures 2 to 6 It is an enlarged view of the components of the bonding head 2. The joint head 2 is fastened on the underside of a wheel 3 , which is rotatable about a vertical axis of rotation D on the joint device 1 in a manner not shown. To generate the rotation, in this embodiment a toothed belt 4 shown only partially can be provided, which meshes with the external toothing of the wheel 3 and which is driven by a driven wheel, not described, wrapped around it by a section according to The desired distance of the corner. An additional driving device can also be provided to make the entire bonding head 2 move laterally in different directions in a plane perpendicular to the rotation axis D. The bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com