Process for combating the appearance of haze during the coating of flexible supports with a crosslinkable liquid silicone composition, in a roll device

A technology of silicone coating and cloth flexibility, which is applied in the field of preventing fogging when coating a flexible carrier with a crosslinkable liquid silicone composition in a roll device, and can solve problems such as not providing quantitative factors for evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0208] Example 1 - Preparation of anti-fogging additive E1 according to the invention

[0209] In a 1L three-neck flask equipped with an anchor stirrer and a nitrogen flow inlet and outlet, add 150 g of polydimethylsiloxane (viscosity at 25 ° C is 1000 cP) with a trimethylsilyl end group, 72 g of polydimethylsiloxane (viscosity 14000 cP at 25° C.) containing hydroxyl functional end groups and 7.2 g of a partially hydrolyzed condensate of ethyl silicate (commonly known as partially hydrolyzed polyethyl silicate). The mixture was stirred and 0.9 g of basic catalyst (solution of potassium silanolate in octamethylcyclotetrasiloxane, KOH equivalent content 14% by weight) were added. The mixture was heated to 130°C. Keep stirring and heating. Then add 5g of silicon dioxide (Nippon Aerogel company's The specific surface area is 200m 2 / g) and 4.7 g of polydimethylsiloxane with hydroxyl end groups (viscosity 50 cP at 25° C.) and homogeneously disperse them with the aid of a homom...

Embodiment 2

[0210] Example 2: Preparation of anti-fogging additive E2 according to the invention

[0211] The anti-fogging additive was prepared in two steps. Step 1 can obtain ultra-high molecular weight resin.

[0212] step 1:

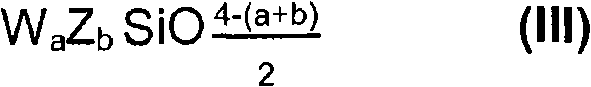

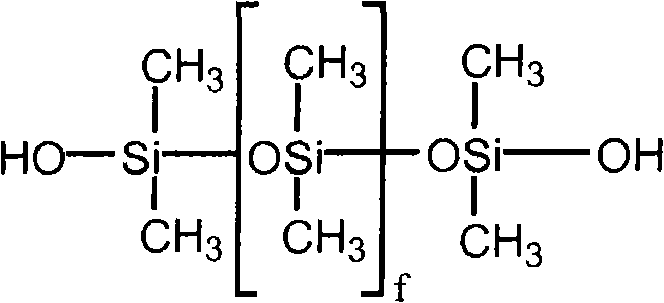

[0213] The molecular weight (Mw) is equal to 12,900, and the general formula is SiO 1.3 (OH) 1.28 Me 0.12 The solid MQ resin (A), the general formula is HO(Me 2 SiO) 15 H's linear polydimethylsiloxane (B) with ≡SiOH end groups and xylene were reacted in a three-necked flask equipped with an apparatus commonly referred to as Dean-Stark and a condenser to prepare an ultrahigh molecular weight MQ resin. The molecular weight (Mw) of compound (A) was 12,900. Compound (B) is preferably a linear polydimethylsiloxane with ≡SiOH end groups having the formula HO(Me 2 SiO) 15 H. The weight ratio of (A) / (B) is 15.7 / 1. The reaction mixture was heated at reflux (140°C) while maintaining constant agitation for 24 hours during which time ammonia catalyst was continuo...

Embodiment 3

[0216] Example 3: Preparation of anti-fogging additive E3 according to the invention

[0217] In a 1L three-necked bottle equipped with a stirrer and a nitrogen purging system, add 280 g of polydimethylsiloxane with a trimethylsilyl end group with a viscosity of 100 mPa·s at 25 ° C, 505 g of polydimethylsiloxane at 25 Polydimethylsiloxane with hydroxyl end groups having a viscosity of 14000 mPa·s at °C and 165 g of a hybrid polysiloxane containing approximately 31% of MQ resin with an OH content of 0.7% by weight . The mixture was stirred and then 30.7 g of basic catalyst (a solution of potassium silanolate in octamethylcyclotetrasiloxane, KOH equivalent content 14% by weight) were added. Stirring was maintained for 45 minutes, then 38.4 g of silicon dioxide ( Precipitated silica provided by Rhodia Company) and uniformly dispersed by means of a homomixer. The mixture was then quenched by heating at 160°C for 1 hour and then cooled to ambient temperature. A viscous product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com