Paddle floating-type stirring machine

A floating type, mixer technology, applied in mixers, mixers, dissolving and other directions with rotary stirring devices, can solve the problems that it is difficult to achieve uniform distribution and wall hanging of feeding materials, and achieve simple structure, convenient processing and improved efficiency. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

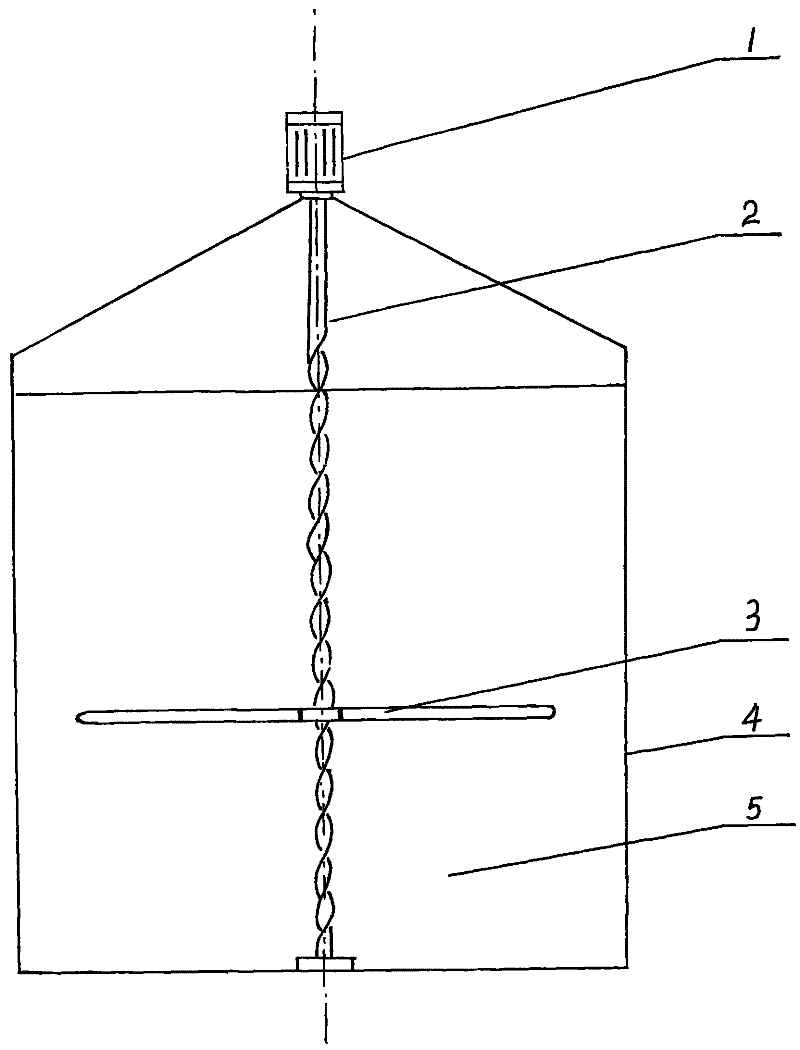

[0017] Such as figure 1 As shown, the variable frequency motor (1) can adjust the rotation speed during operation to achieve the purpose of adjusting the position of the blade.

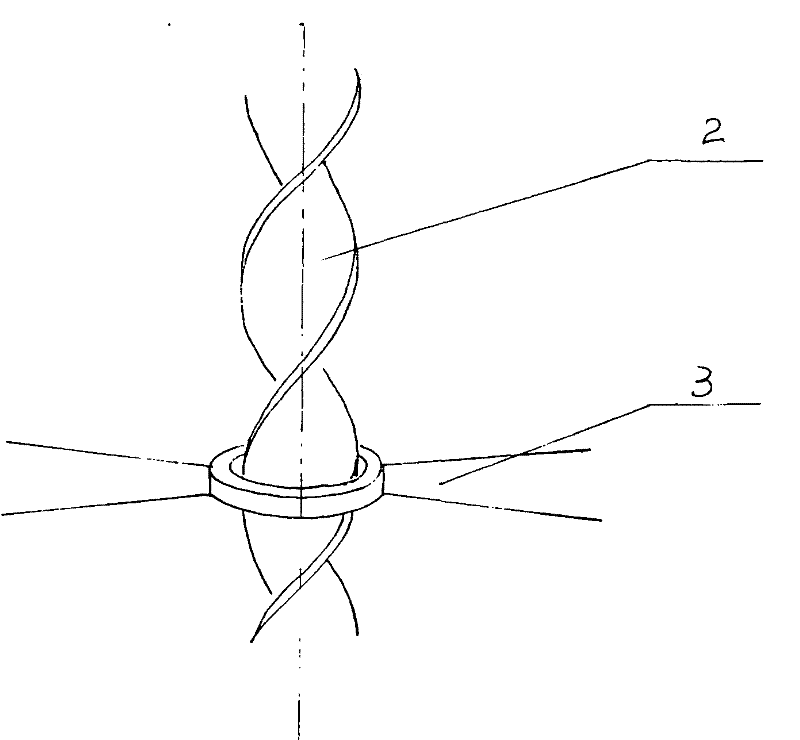

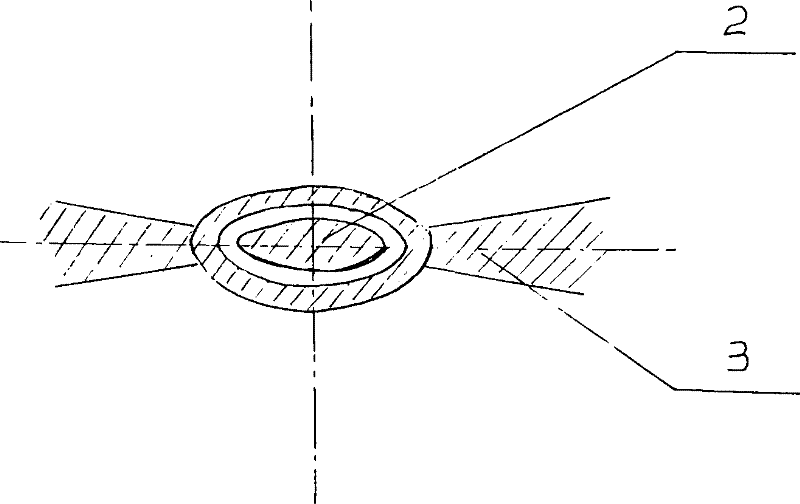

[0018] When the screw shaft (2) stops or the speed slows down, the floating stirring blade (3) will slide down or move up along the screw shaft (2) due to the influence of gravity and buoyancy only, and finally suspend in the solid-liquid mixture ( 5) the surface or bottom;

[0019] When the screw shaft (2) rotates rapidly, the floating stirring blade (3) is subjected to tangential force, and the floating stirring blade (3) will move along the screw shaft (2) depending on the direction of rotation of the screw shaft (2). direction movement;

[0020] Through the above two states, the movement up and down in the tank can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com