Manufacturing method of rare earth alloy powder, rare earth alloy powder thereof and permanent magnet

A technology of rare earth alloy and manufacturing method, applied in the field of rare earth alloy powder and permanent magnet, can solve the problems of complex reaction mechanism, change of magnetic properties such as coercive force of magnet powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

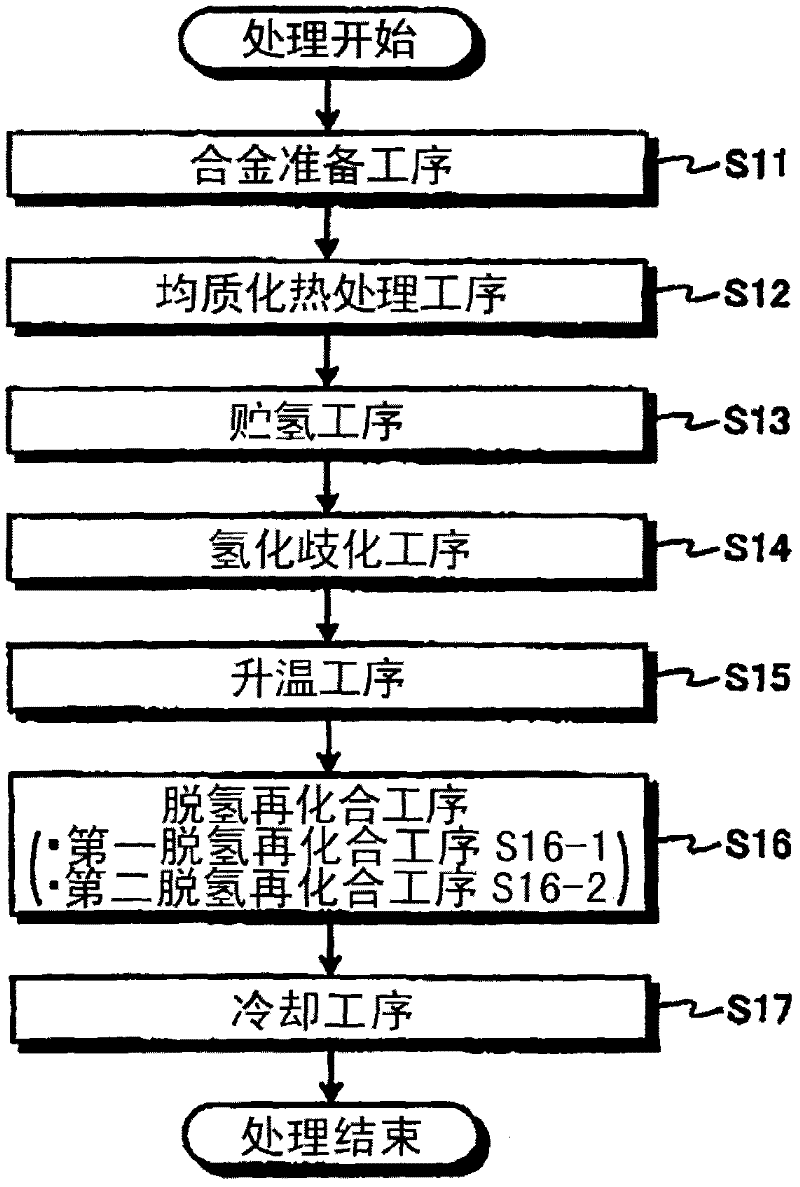

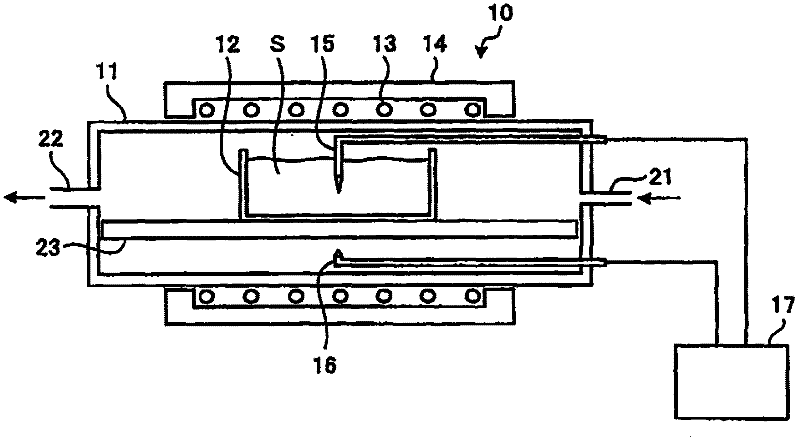

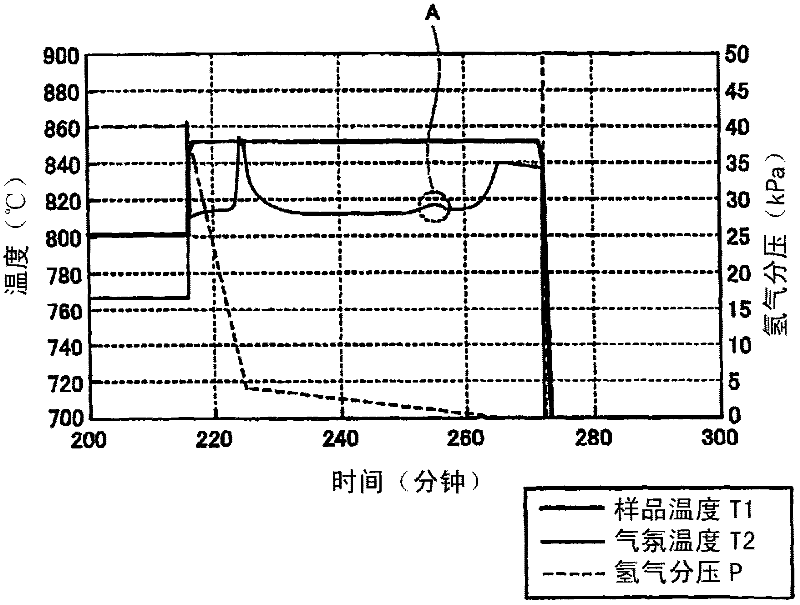

[0046] A suitable method for producing the rare earth alloy powder according to the embodiment of the present invention will be described with reference to the drawings. The method for producing rare earth alloy powder according to the present embodiment is a method for producing rare earth alloy powder by performing HDDR. The HDDR method is to heat the raw material (starting alloy) in hydrogen to hydrogenate the raw material - disproportionation (HD: Hydrogenation Decomposition), and then make it dehydrogenation - recombination (DR: Desorption Recombination), thereby making the crystal finer, And the method for manufacturing rare earth alloy powder. figure 1 It is a flow chart showing the manufacturing method of the rare earth alloy powder of 1st Embodiment of this invention. Such as figure 1 As shown, the production method of the rare earth alloy powder of the present embodiment includes the following steps: casting R 2 T 14 Alloy preparation process (step S11) of obta...

Embodiment 1

[0120] Nd with the following composition was prepared using the strip casting method (SC) 2 (Fe, Co) 14 B raw material alloy (grain size is about 30.0mm, hereinafter referred to as "raw material alloy".) ( figure 1 In the alloy preparation process (step S11)). According to this embodiment figure 1 The process shown is carried out.

[0121] Nd: 29.8% by mass

[0122] Fe: 63.1% by mass

[0123] Co: 5.0% by mass

[0124] B: 1.18% by mass

[0125] Ga: 0.36% by mass

[0126] Nb: 0.30% by mass

[0127] This raw material alloy contains trace amounts of unavoidable impurities (0.2 to 0.3% by mass of the whole raw material alloy) in addition to the above-mentioned elements. The raw alloy is kept in a vacuum at a temperature ranging from 1000°C to 1200°C for 24 hours ( figure 1 In the homogenization heat treatment process (step S12)). The homogenized heat-treated raw material alloy is pulverized with a pounder, and sieved to obtain a powdered raw material alloy (with a par...

Embodiment 2

[0135] In Example 2, the HDDR-treated rare earth alloy powder was obtained in the same manner as in Example 1 except that the temperature dropped in the second DR step (step S16-2) was changed from 650°C to 620°C. This rare earth alloy powder was used as magnet powder for magnet molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com