A kind of copolyester compound and preparation method

A technology of compound and copolyester, which is applied in the field of copolyester of biological source raw materials, can solve the problems of limited application range and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

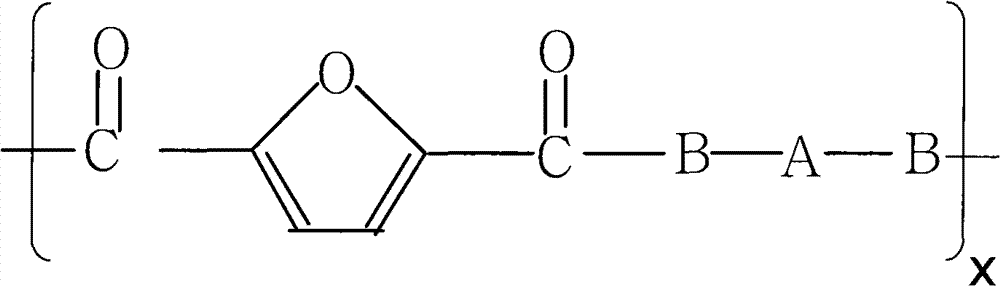

AI Technical Summary

Problems solved by technology

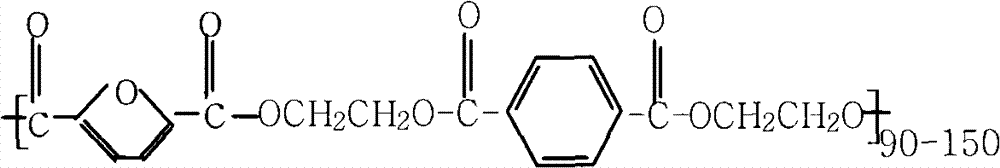

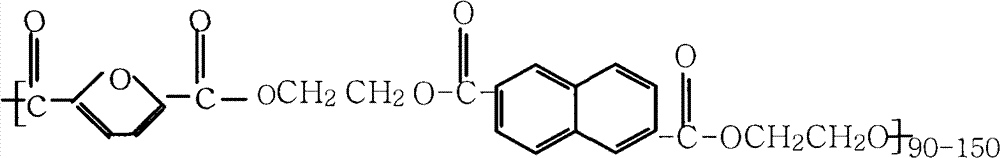

Method used

Image

Examples

Embodiment 1

[0024] At a temperature of 250° C., 166 parts by weight of terephthalic acid and 75 parts by weight of bio-sourced ethylene glycol (product of Dacheng Group) were directly esterified to obtain a first prepolymer.

[0025] At a temperature of 160° C., 89 parts by weight of 2,5-furandicarboxylic acid (Mianyang High-tech Zone Gaote Technology Co., Ltd. product) and 212 parts by weight of biological source ethylene glycol (Dacheng Group product) were esterified ( ES reaction), obtain the second prepolymer.

[0026] The first prepolymer and the second prepolymer are weighed to calculate the ratio of furandicarboxylic acid group and terephthalic acid group in the product copolyester compound to be 5: 95, and the two kinds of low prepolymers weighed Mix well, put into the polymerization test tube, the addition amount of tetrabutyl titanate (AR, product of Shanghai Shisi Hewei Chemical Co., Ltd.) of the polymerization catalyst is 100ppm with respect to the copolyester compound total a...

Embodiment 2

[0029] At a temperature of 250° C., 166 parts by weight of terephthalic acid and 75 parts by weight of bio-sourced ethylene glycol (product of Dacheng Group) were directly esterified to obtain a first prepolymer.

[0030] At a temperature of 160° C., 89 parts by weight of 2,5-furandicarboxylic acid (Mianyang High-tech Zone Gaote Technology Co., Ltd. product) and 212 parts by weight of biological source ethylene glycol (Dacheng Group product) were esterified ( ES reaction), obtain the second prepolymer.

[0031] The first prepolymer and the second prepolymer are weighed to calculate the ratio of furandicarboxylic acid group and terephthalic acid group in the product copolyester compound to be 8:92, and the two kinds of low prepolymers weighed Mix well, put into the polymerization test tube, the addition amount of tetrabutyl titanate (AR, product of Shanghai Shisi Hewei Chemical Co., Ltd.) of the polymerization catalyst is 100ppm with respect to the copolyester compound total am...

Embodiment 3

[0033] At a temperature of 250° C., 166 parts by weight of terephthalic acid and 75 parts by weight of bio-sourced ethylene glycol (product of Dacheng Group) were directly esterified to obtain a first prepolymer.

[0034] At a temperature of 160° C., 89 parts by weight of 2,5-furandicarboxylic acid (Mianyang High-tech Zone Gaote Technology Co., Ltd. product) and 212 parts by weight of biological source ethylene glycol (Dacheng Group product) were esterified ( ES reaction), obtain the second prepolymer.

[0035] The first prepolymer and the second prepolymer are weighed to calculate the ratio of furandicarboxylic acid group and terephthalic acid group in the product copolyester compound to be 10:90, and the two kinds of weighed low prepolymer Mix well, put into the polymerization test tube, the addition amount of tetrabutyl titanate (AR, product of Shanghai Shisi Hewei Chemical Co., Ltd.) of the polymerization catalyst is 100ppm with respect to the copolyester compound total amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com