Emulsified asphalt with strong compatibility, and preparation method thereof

A technology of emulsified asphalt and compatibility, applied in the field of emulsified asphalt with strong compatibility and its preparation, can solve the problems of restricting the promotion and application of emulsified asphalt technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

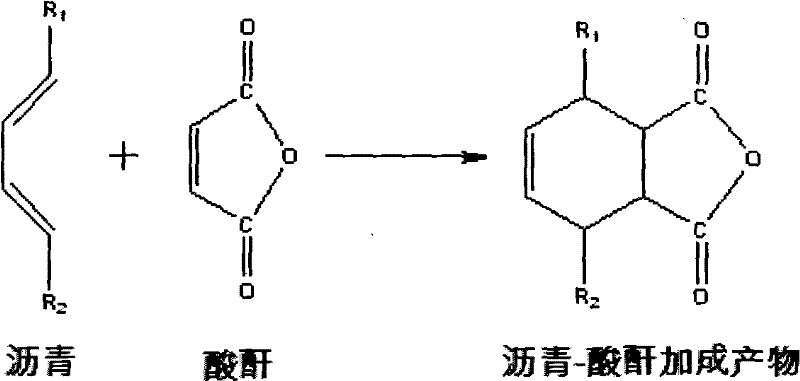

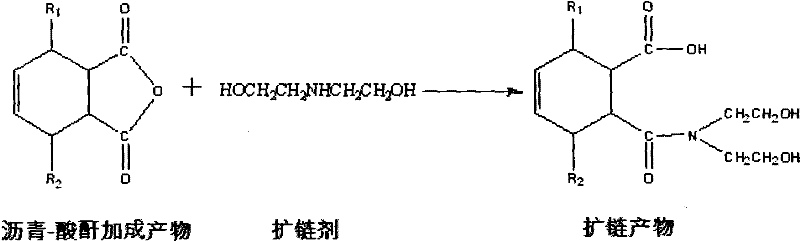

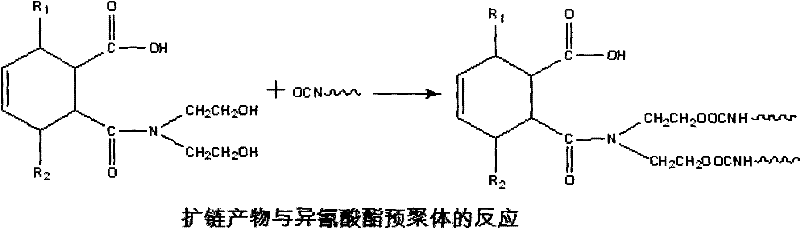

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of modified asphalt

[0035] Heat 80 parts of base asphalt to 100-160°C, remove moisture, add 2 parts of maleic anhydride and 0.3 parts of N,N-dimethylaniline, and react for 3-6 hours; add 1 part of diethanolamine, and react for 2-4 hours; Slowly add 16.7 parts of isocyanate prepolymer, control the feeding speed, and finish adding within 2 to 3 hours. Continue to react for 2 hours after the feeding is complete to obtain the modified asphalt.

[0036] (2) Soap preparation

[0037] Prepare 2 parts of C500 emulsifier (AkzoNobel), 0.5 part of polyvinyl alcohol, 36 parts of water and 1.5 parts of hydrochloric acid to prepare a soap solution, and heat it to 60-70°C.

[0038] (3) Asphalt emulsification

[0039] Heat the above-mentioned modified asphalt to 130-150°C, emulsify the above-mentioned soap solution and modified asphalt in the emulsification equipment, and then the emulsified asphalt product will be produced.

[0040] The performance indicators of ...

Embodiment 2

[0043] (1) Preparation of modified asphalt

[0044] Heat 85 parts of base asphalt to 100-160°C, add 3 parts of maleic anhydride and 0.5 parts of N,N-dimethyl-p-toluidine after dehydration, react for 3-6 hours; add 1.2 parts of diethanolamine, react for 2- 4h; Slowly add 10.3 parts of isocyanate prepolymer, control the feeding speed, and finish adding within 2-3 hours. Continue to react for 2 hours after the feeding is complete to obtain the modified asphalt.

[0045] (2) Soap preparation

[0046] Prepare soap solution by preparing 3.5 parts of MQK-1D emulsifier (Medwishvik Co.), 0.5 parts of calcium chloride, 33.4 parts of water and 2.6 parts of hydrochloric acid, and heat it to 60-70 °C.

[0047] (3) Asphalt emulsification

[0048] Heat the above-mentioned modified asphalt to 130-150°C, emulsify the above-mentioned soap solution and modified asphalt in the emulsification equipment, and then the emulsified asphalt product will be produced.

[0049] The performance indicato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com