Full-photopic-vision microorganism solid-state fermentation tank

A solid-state fermenter and microbial technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc. , Low production efficiency and other issues, to achieve the effect of shortening the fermentation cycle, less operating workload, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

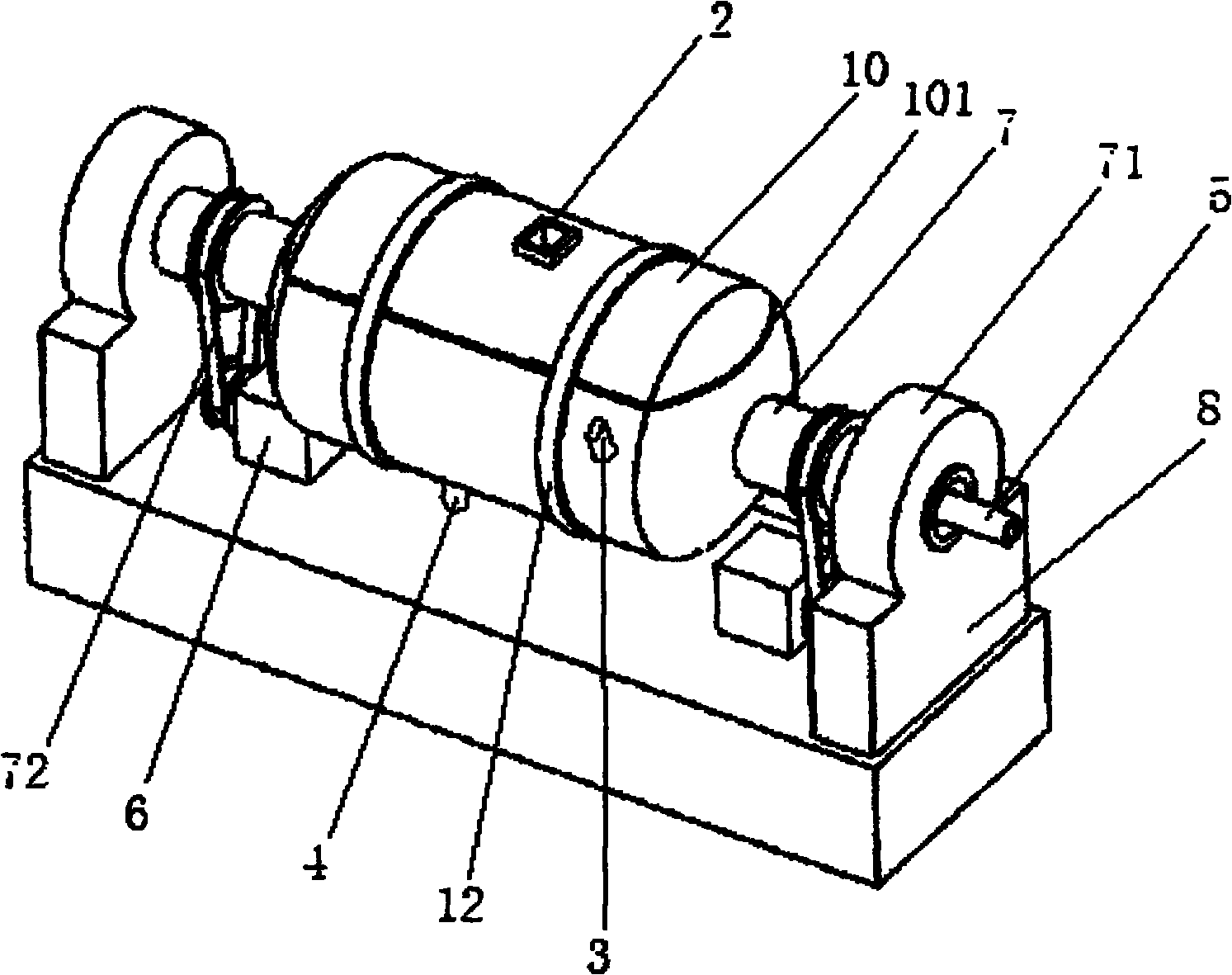

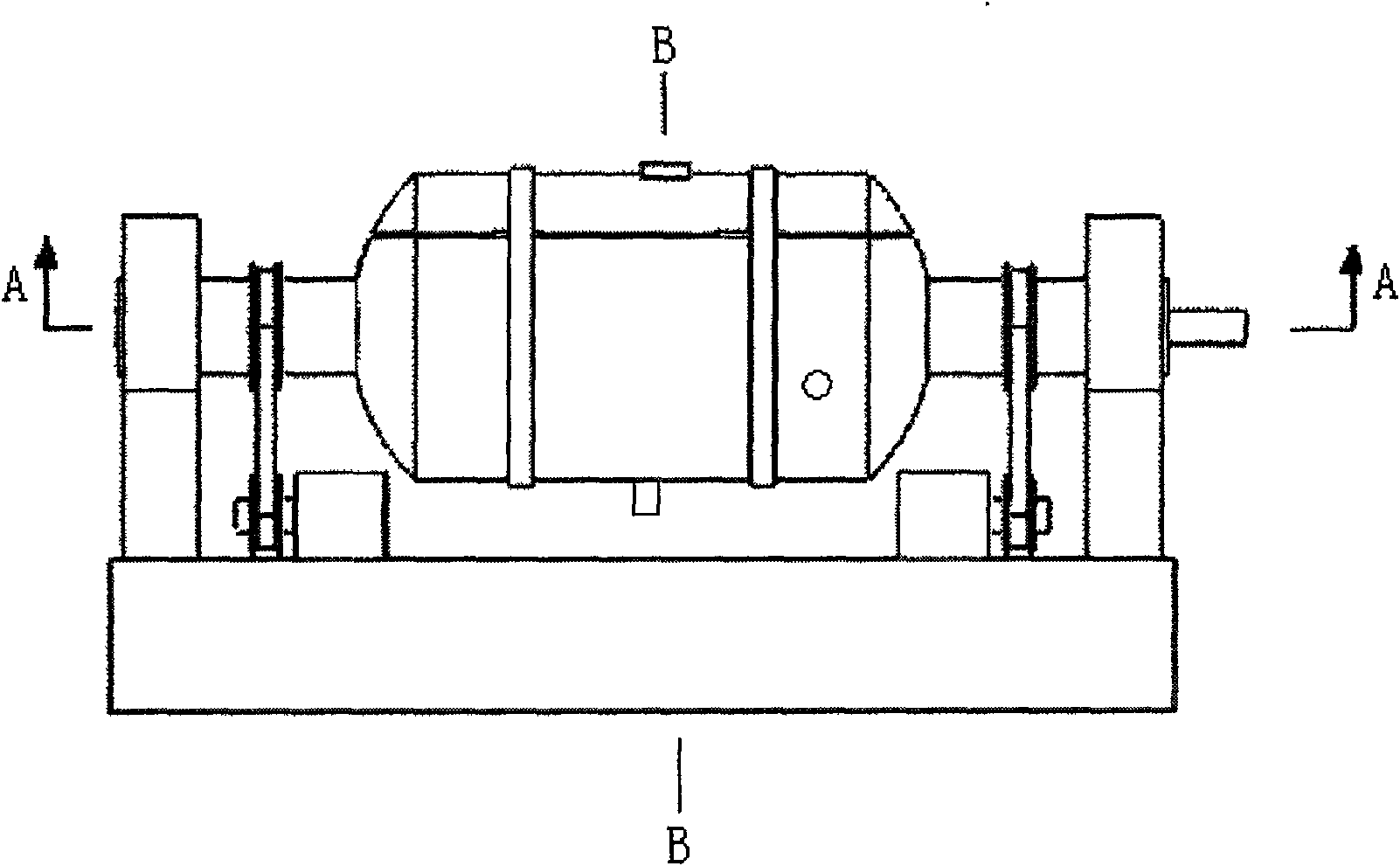

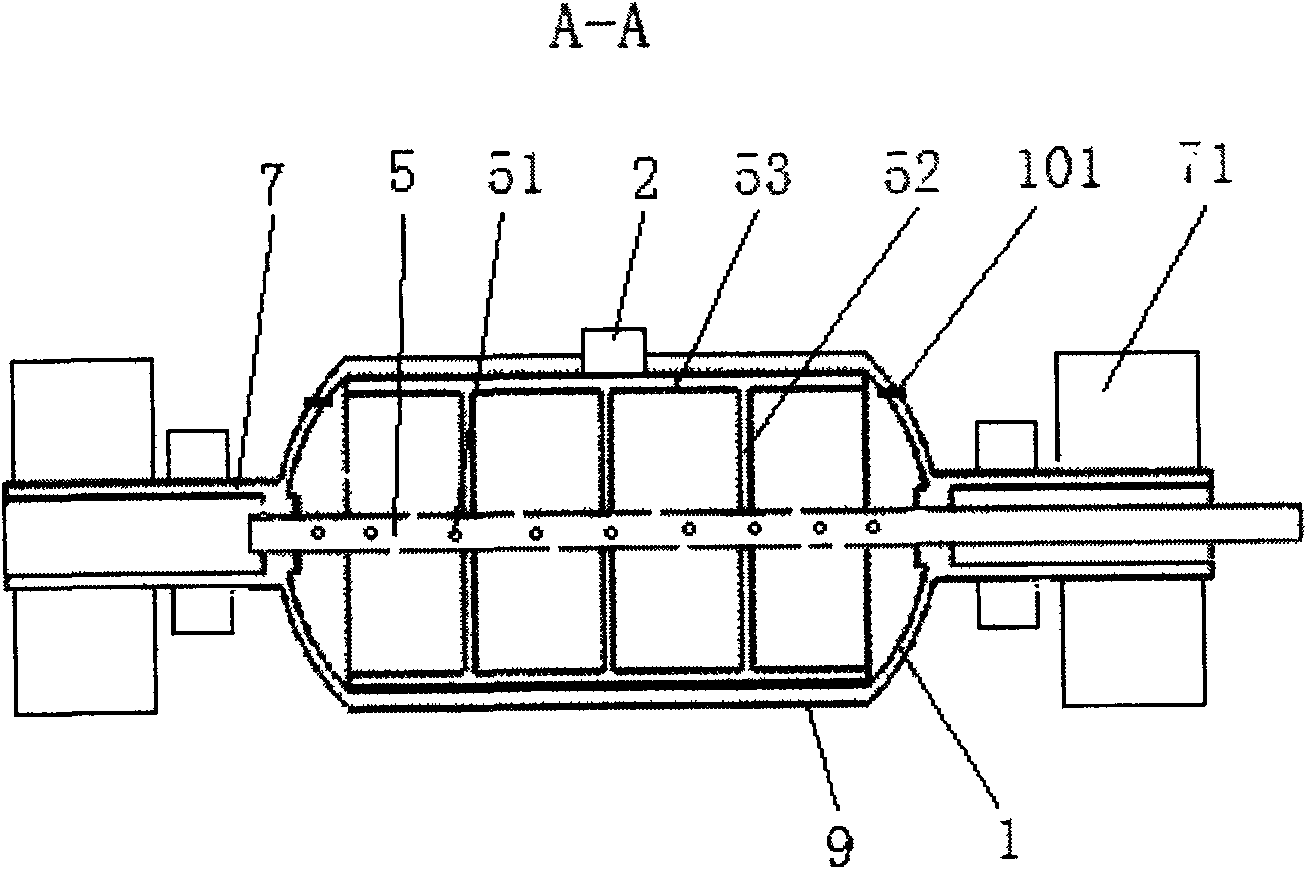

[0016] Such as figure 1 , 2 , 3, and 4, the present invention includes a tank provided with an inner liner 1 densely covered with micropores (not shown in the figure), and a clamp is provided between the inner liner 1 and the tank shell 9 Cavity. The tank body is provided with a feed port 2, a tail gas discharge port 3 and a waste liquid discharge port 4, wherein the feed port 2 is arranged on the tank body cover. It also includes a hollow shaft 5 movably connected to both ends of the tank body, and a motor 6 that drives the tank body to rotate (in this embodiment, a forward and reverse motor is selected).

[0017] Such as image 3 As shown, one end of the hollow shaft 5 passes through the tank body, and then passes through the connecting piece 7 (the connecting piece 7 is cylindrical) at the end of the tank body. The end of the hollow shaft 5 at this end is a through hole (other One end is sealed), the hollow shaft 5 in the tank is provided with gas discharge holes 51, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com