Bismuth-titanium alloy and application thereof

A technology of titanium alloy and alloy liquid, applied in the field of alloy steel (C22C alloy) preparation, can solve the problems of large burning loss of bismuth element, difficulty in realizing industrial application, difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

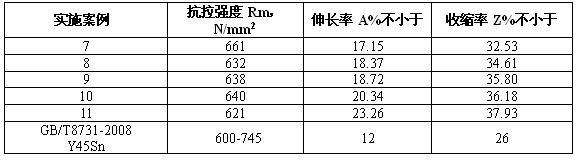

Examples

Embodiment 1

[0014] Embodiment 1: a kind of bismuth-titanium alloy, its component and the weight percentage of each component are (%): bismuth 15, the sum of unavoidable impurity sulfur, phosphorus, silicon etc.≤0.8, the balance is titanium; Its products are lumpy, with a lumpiness of 45mm.

Embodiment 2

[0015] Embodiment 2: a kind of bismuth-titanium alloy, its component and the weight percent of each component are (%): bismuth 59, the sum of unavoidable impurity sulfur, phosphorus, silicon etc. ≤ 0.8, the balance is titanium; Its products are granular, with a particle size in the range of 0.5-10mm.

Embodiment 3

[0016] Embodiment 3: a kind of bismuth-titanium alloy, its component and the weight percentage of each component are (%): bismuth 64, the sum of unavoidable impurity sulfur, phosphorus, silicon etc. ≤ 0.8, the balance is titanium; Its products are lumpy, with a lumpiness of 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com