Spiral rock splitter

A technology of spiral rock and splitting machine, applied in the field of rock splitting machine, can solve the problems of long production cycle, heavy equipment and high production cost, and achieve the effects of convenient transportation and use, easy assembly and maintenance, and energy saving and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

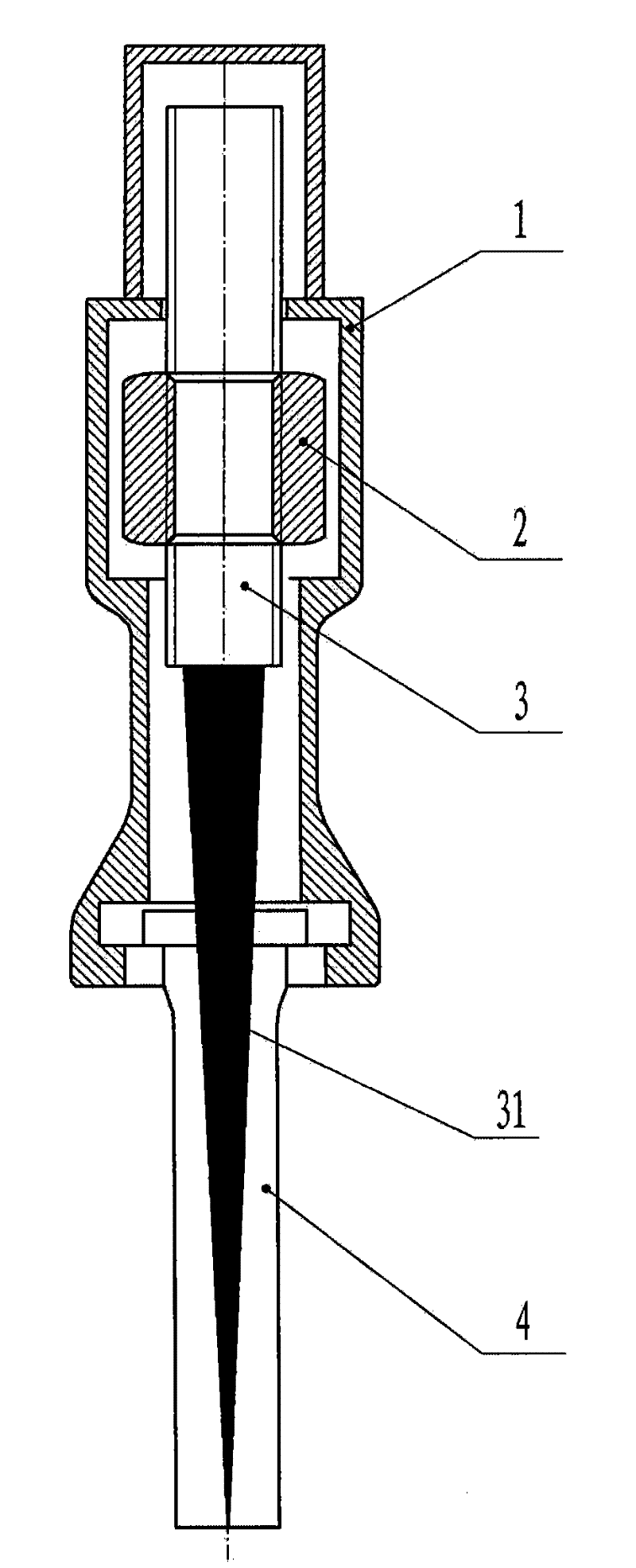

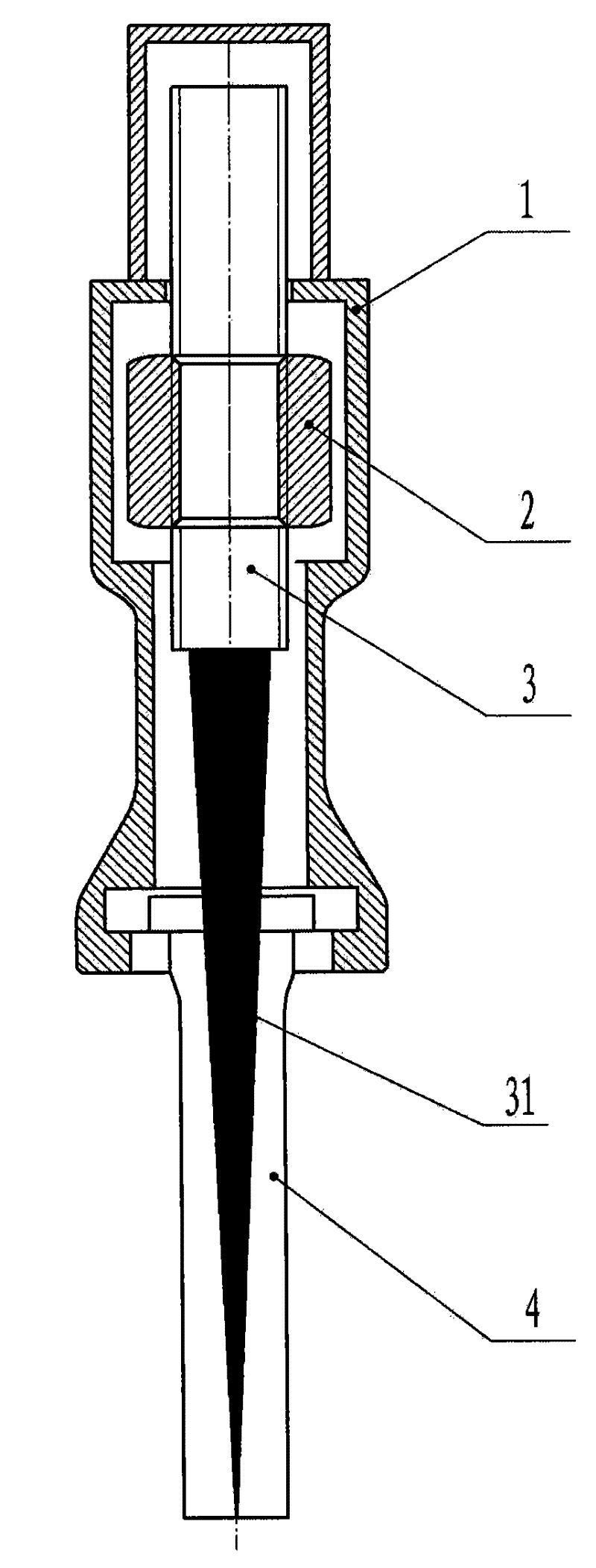

[0019] The present invention includes: a cage 1; a nut 2 is placed in the inner cavity of the cage 1; a screw 3 is placed in the middle of the nut 2; the screw 3 is connected to the middle wedge 31 at its lower end or the middle wedge 31 is connected to the nut 2 are connected; the side wedges 4 are arranged on both sides of the middle wedge 31.

[0020] In the structure of the present invention, the nut 2 rotates around the central axis, and the screw mandrel 3 can move up and down in a straight line without being able to rotate; it is also possible to allow the screw mandrel 3 to perform a rotational movement, while the nut 2 moves linearly along the central axis, so as to achieve the same driving structure effect. The screw rod in the structure of the present invention can be a threaded screw rod or a ball screw rod.

[0021] Through manual,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com