Transmission for a car

A technology for transmission and vehicle, applied in the direction of vehicle transmission, vehicle components, components with teeth, etc., can solve problems such as complex structure, and achieve the effects of reducing pollution, reducing vibration sensitivity, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In the following description, embodiments of the present application will be described in detail. It will be apparent, however, to one skilled in the art that the embodiment may be practiced without these details.

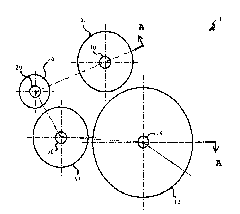

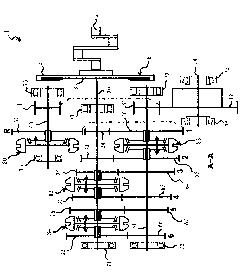

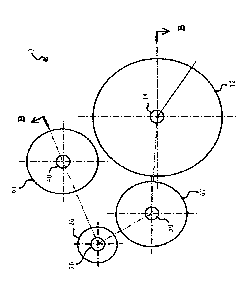

[0092] Figure 1-2 A detailed description of a first embodiment of the transmission 1 of the present application is provided.

[0093] The transmission 1 comprises a larger output gear 12 on an output shaft 14 , an input shaft 20 and two pinions 41 , 51 on two layshafts 40 , 50 . The input shaft 20 is non-rotatably connected to the clutch disc 8 of the clutch 6 . The two pinions 41 , 51 are the upper pinion 41 or reverse pinion 41 , and the lower pinion 51 or layshaft pinion 51 . On their axes of rotation, the upper pinion 41 is fixed to the upper layshaft 40 or reverse layshaft 40 and the lower pinion is fixed to the lower layshaft 50 or layshaft 50 , respectively. The two pinions 41 , 51 mesh with the output gear 12 at different positions of the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com